CNC plasma cutters may sound like something out of a science fiction movie, but they are actually incredible machines that can do some pretty amazing things!

CNC stands for Computer Numerical Control, which means that these machines are controlled by computers. Plasma cutters, on the other hand, are tools that use a high-temperature jet of ionized gas, called plasma, to cut through various materials with precision. When you combine the power of CNC technology with plasma cutting, you get CNC plasma cutters.

Now let’s embark on an exciting journey to discover their remarkable uses.

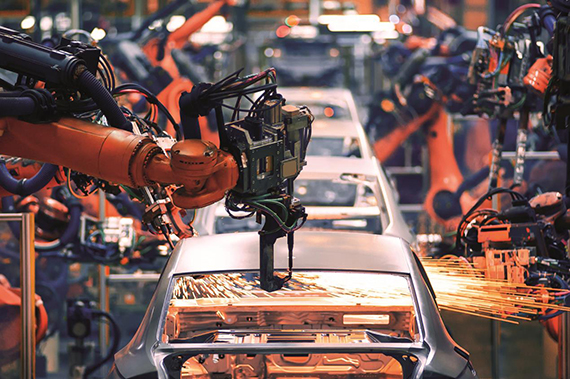

#1 Automotive Manufacturing

The automotive industry is one of the sectors where CNC plasma cutters have made a significant impact. CNC plasma cutters can precisely cut metal sheets into specific shapes required for components like car frames, chassis, brackets, and panels. By following computer-generated designs, CNC plasma cutters ensure that each part is cut with utmost accuracy and consistency. This precision is vital for ensuring that the car parts fit together perfectly during assembly.

Moreover, CNC plasma cutters can handle a wide range of materials used in the automotive industry, including steel, aluminum, and even specialized alloys. This versatility allows manufacturers to create parts with different characteristics, such as strength, lightness, or heat resistance, depending on the requirements of the specific component.

Recommended Read: CNC Plasma Cutters: 3 Hidden Secrets Only Experts Know

#2 Home Decor and Interior Design

CNC plasma cutters have become a go-to tool for artisans and designers when it comes to crafting intricate and eye-catching decorative metal elements. These machines can transform metal sheets into stunning designs, including ornate patterns, intricate filigree, and elaborate motifs.

From decorative wall panels and room dividers to stunning stair railings and intricate lampshades, CNC plasma cutters enable the creation of unique and captivating metal elements that add a touch of elegance and sophistication to any home. The precision and versatility of these machines allow designers to explore various shapes, sizes, and textures, bringing their creative visions to life with astonishing detail.

One of the most exciting aspects of CNC plasma cutters is their ability to personalize home accents. These machines can be programmed to cut out specific designs, names, or monograms, offering homeowners the opportunity to create personalized pieces that truly reflect their individuality.

Imagine having a customized metal sign with your family name hanging at your front door or personalized wall art featuring your favorite quotes or symbols. CNC plasma cutters make it possible to turn these ideas into reality, giving homeowners the chance to add a personal touch to their living spaces.

Furthermore, CNC plasma cutters can be used to create personalized home accents for special occasions or events. Whether it’s a unique centerpiece for a wedding or custom-made decorations for a birthday party, these machines allow for limitless creativity and customization.

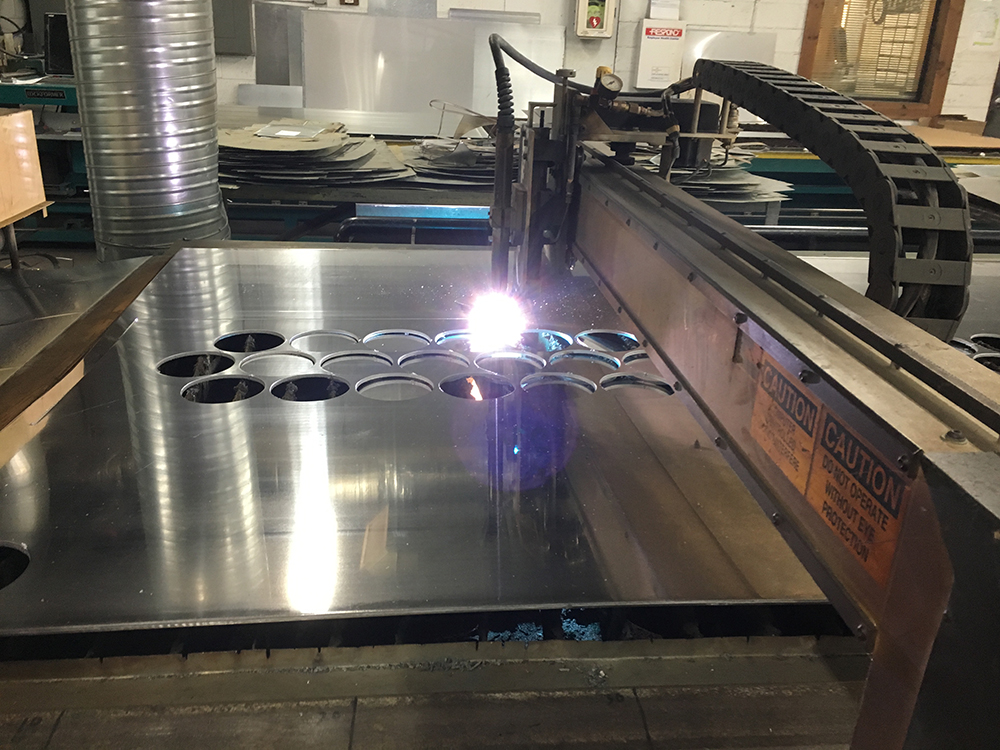

#3 Equipment Repair and Modification

CNC plasma cutters provide an invaluable tool for repairing damaged machinery parts. When a component becomes worn out, damaged, or needs to be replaced, CNC plasma cutters can precisely cut out the necessary replacement part with accuracy and speed.

CNC plasma cutters are able to ensure that the repaired part perfectly matches the original specifications. This precise replication guarantees a seamless fit and functionality within the machinery. Whether it’s a broken gear, a worn-out bracket, or a damaged flange, CNC plasma cutters can recreate the exact shape and dimensions required for the repair.

In addition to repairs, CNC plasma cutters are instrumental in modifying machinery parts to improve performance or meet specific requirements. Sometimes, machinery parts need to be customized to adapt to new operating conditions, accommodate technological advancements, or optimize efficiency.

CNC plasma cutters enable technicians to accurately cut, shape, and modify existing parts with precision. They can remove sections, create new openings, or add additional features to enhance the functionality of the machinery. This flexibility allows for the adaptation and customization of equipment to suit evolving needs.

Whether it’s modifying a conveyor belt system, retrofitting a control panel, or altering the design of a hydraulic component, CNC plasma cutters provide the means to achieve precise and efficient modifications. Technicians can rely on these machines to ensure that the modified parts integrate seamlessly into the existing machinery, maintaining overall performance and reliability.

#4 Salvage and Recycling

When dealing with large pieces of scrap metal, such as old machinery, vehicles, or structural components, Plasma cutters can precisely cut through the material, separating it into smaller, manageable pieces. CNC plasma cutters ensure that the salvage process is carried out with utmost precision and efficiency. Technicians can identify and cut out sections of the scrap metal that contain valuable materials or components, such as steel plates, pipes, or electrical wiring. These salvaged materials can then be repurposed or used in other manufacturing processes, reducing the need for new raw materials and minimizing waste.

CNC plasma cutters have also made significant contributions to the recycling industry by facilitating the processing of scrap metal and increasing the efficiency of recycling operations. These machines enable the precise separation of different metal components, making it easier to sort and recycle materials based on their specific properties.

In recycling facilities, CNC plasma cutters are utilized to disassemble large and complex metal structures, such as appliances, vehicles, and industrial equipment. They can cut through these items with precision, separating them into individual components or materials that can be recycled separately. This process allows for more efficient recycling and reduces the amount of waste that goes to landfills.

Related Posts

- CNC Plasma Cutters: 3 Hidden Secrets Only Experts Know

CNC plasma cutters have revolutionized the world of precision cutting and fabrication. With their remarkable versatility and precision, these machines have become an integral part of numerous industries. In this…

- What is a CNC Plasma Cutter?

In the fast-paced world of CNC machining, where precision and efficiency reign supreme, the CNC Plasma Cutter emerges as a groundbreaking tool. If you're new to the realm of CNC…

- The Role of Precision in CNC Machining: How Tight Tolerances Impact Cost and Quality?

Introduction: Understanding Precision in CNC Machining In manufacturing contexts, precision is epitomized by Computer Numerical Control (CNC) machining. In essence, CNC machining is a process utilized widely within the manufacturing…