Precision Machining of Brass: An Introduction

Precision machining is a fundamental manufacturing process that entails the meticulous removal of material from a workpiece, to create precise components with specified dimensions and tolerances. The objective of this operation is to produce high-quality parts with utmost precision and accuracy, by utilizing advanced machine tools and techniques.

The critical role of brass in precision machining cannot be overstated. Often favored due to its excellent machinability, durability and corrosion resistance, brass enables manufacturers to create complex shapes and designs with ease and efficiency. This versatile alloy facilitates smoother machining operations, reduces tool wear, and extends the longevity of machinery, making it an exemplar choice for intricate medical applications requiring superior strength and reliability. Some examples include surgical instruments, implants, and medical equipment where accuracy is paramount:

- Surgical Instruments – Brass provides the required hardness yet flexibility to design precision surgical instruments like forceps, scalpel handles or needle holders, ensuring their utility and effectiveness during complicated procedures.

- Implants – Intricate brass-based alloys are often used in the creation of bio-compatible implants such as joint replacements due to their biocompatibility, durability and resistance to corrosion.

- Medical Equipment – Many essential medical devices, including diagnostic equipment and patient monitoring systems, incorporate meticulously machined brass components for maintaining long-lasting performance and operational accuracy.

The Versatility of Brass in Medical Applications

The remarkable properties of brass position it as an ideal choice for various medical applications. Brass, a combination of copper and zinc, exhibits antibacterial capabilities; hence, making it well-suited to maintain hygiene standards pertinent to the healthcare industry. This quality is supremely important in high-contact areas or pieces such as door handles and bed rails. Moreover, brass affords excellent corrosion resistance and strength which makes it indispensable in critical instruments. It also offers impressive machinability that enables intricate detailed designs imperative for certain surgical tools.

For instance, consider the use of a brass-made stethoscope. Well-known for its acoustic properties, a brass-head stethoscope delivers clear sound transmission, thereby aiding precise diagnosis. Furthermore, due to its non-ferromagnetic property, it eliminates any signal interference especially near MRI machines.

- Antibacterial qualities: Helpful in maintaining cleanliness and hygiene in health care settings.

- Corrosion-resistance and strength: Effective longevity, durability, and performance under diverse hospital environments.

- Machinability: Allows fabrication of complex components required for specialized medical procedures.

Thus, with key features like inherent toughness, malleability, and acoustical advantages, brass presents itself as a versatile option not only in terms of utility but also concerning patient safety and comfort within medical domains. These attributes ensure that precision machining of brass shapes a vital constituent of custom solutions for a variety of medical applications.

Custom Solutions: Tailoring Brass Equipment for Medical Needs

The process of precision machining allows brass components to be custom designed specific to individual medical needs, recognizing the critical significance of personalization in healthcare applications. A myriad of health factors often necessitate a unique set of requirements, underscoring the importance of bespoke fabrication in therapeutic devices. For instance, patients suffering from chronic respiratory issues may require specially tailored connectors and valves made from brass for their oxygen concentrators. These deliver measured amounts of concentrated oxygen directly to them via nasal cannulas, assisting in managing their condition efficiently.

- Brass Connectors: Enables seamless interconnection between device modules, ensuring efficient gas flow.

- Brass Valves: Regulates the release of oxygen at suitable pressures, aiding in patient comfort and safety.

This case exemplifies how custom machining of brass can play a crucial role in creating personalized solutions catering exactly to distinct medical necessities. Such an approach strengthens the effectiveness of care delivery and broadens the horizon of advancements in the field of medicine.

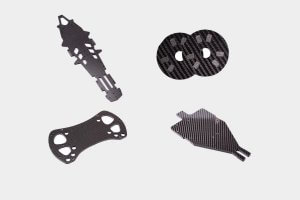

The process of precision machining for brass involves the production of accurate components with high tolerances and excellent surface quality. This is achieved by removing materials from a workpiece using various techniques such as turning, milling, drilling, and grinding. Precision CNC machining can be carried out using a wide variety of materials, including brass, which is suitable for industries such as electrical goods, consumer goods, architecture, automotive, and healthcare.

The Influence of Technological Advancements in Precision Machining

Technological advancements have greatly influenced the precision machining industry, more specifically in crafting custom brass solutions for medical applications. High-precision machinery like CNC (Computer Numerical Control) machines uses software control systems to cut and shape brass with extreme accuracy. Specific devices such as:

- Laser-cutting Machines – Aid in the production of intricate designs on the metal surfaces.

- CNC Lathe Machines – Helps ensure consistency in mass production while maintaining a high level of precision.

- Automated Grinding Equipment – Facilitates precision surface finishing.

This technological evolution not only optimizes consistency but also reduces waste generation through precise cuttings which is beneficial both economically and environmentally. Moreover, it ensures safe manufacturing due to reduced manual handling. The introduction of these technologies has made possible the creation of specialized medical items such as tiny screws used in bone surgeries and complex components for medical imaging equipment. Thus technology proves critical to achieving efficacious outcomes in the medical field by delivering accurate and reliable machined parts.

Importance of Quality Control in Producing Precise Brass Instruments

In the generation of precise brass instruments for medical applications, Quality Control (QC) plays a pivotal role. QC ensures that all manufactured items conform to an established set of quality measures and tolerances. This process is indispensable as it guarantees the efficacy and reliability of these critical tools in real-life medical situations.

- The stringent observation of metrics in dimensional accuracy, surface finish, and material properties make certain that each instrument will function as designed with no room for errors.

An example of the repercussions of neglecting accurate quality control can be observed in the recall of a specific brand of surgical forceps in 2017. The forceps broke during surgery due to substandard materials which led not only to setbacks in various surgical procedures but also put patients’ lives at risk. In light of such incidents, consistency in QCs maintains credibility and prevents significant losses from product recalls or malfunctions.

Environmental Considerations in Precision Machining of Brass

In precision machining, particularly with metals like brass, environmental considerations play a crucial role. The process involves the significant use of energy and resources, hence it’s essential to minimize its ecological footprint. With regard to the operations involving brass, industry leaders are continuously striving toward more sustainable techniques.

For instance, when working with brass, manufacturers often recycle chips and offcuts produced by the machining process as an effort towards sustainability. By doing so, they ensure valuable materials are not wasted, reducing both costs and environmental impact.

- Your use of coolant, which can pose potential hazards to ecosystem health, is another area where environmental sensitiveness comes into the picture. Companies today seek out bio-degradable or recyclable options for coolants, thereby minimizing overall harm to the environment.

- Moreover, optimum power usage has also been prioritized, making efficiency a strongly favored quality in machinery selection. With highly-efficient machine tools, the amount of electrical consumption can be significantly reduced, directly lowering carbon emissions associated with electricity production.

By integrating such strategies, ones aimed at enhancing efficacy alongside diminishing negative environmental effects, the precision machining sector represents an excellent example of adopting responsible practices within the industrial domain.

Other Articles You Might Enjoy

- Affordable CNC Machining: Quick Turnaround for Prototype Steel Parts

Introduction: The Role of CNC Machining in Manufacturing Steel Parts CNC (Computer Numerical Control) machining is a pivotal factor in manufacturing steel parts, providing significant benefits ranging from precision to…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Bead Blasting in CNC Machining(sheet metal fabrication Charles)

Bead blasting is an integral process in the world of Computer Numeric Control (CNC) machining. This technique involves the use of high-pressure air or steam to propell tiny glass beads…