Introduction to Aluminum CNC Machining Services

In the world of manufacturing, Aluminum CNC machining services stand as a vital solution. Utilizing computer numerical control (CNC) technology, these high-precision services employ automated machine tools that generate accurate and intricate parts from aluminum—a material renowned for its superior tensile strength, corrosion resistance, and heat dissipation attributes.

Precision and custom solutions in this industry are pivotal. They ensure each component produced meets stringent quality standards and caters effectively for specific utilization needs across various sectors like automotive, aerospace or medical devices industries.

- Precision: Precise results eliminate the risk of errors in part production, ensuring every single measurement is accurate to fractions of a millimeter. This level of precision fosters optimal operating efficiency among machinery composed of CNC machined components while additionally extending their service lifespan.

- Custom Solutions: Customizable services facilitate unique application requirements fulfillment. Be it complex geometrical designs, tight tolerance demands, challenging assembly integrations–a flexible CNC machining process can accommodate such bespoke specifications without compromising on the product’s integrity and performance.

Understanding Aluminum CNC Machining

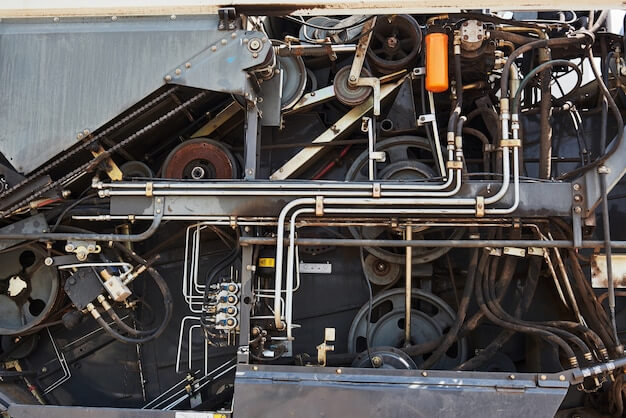

CNC, or Computer Numerical Control machining, is a process used in the manufacturing sector that involves the use of computers to control machine tools. In aluminum CNC machining, this technology is leveraged for precise manipulation of aluminum – a material prized for its light weight and superior strength-to-weight ratio. It allows for accurate, repeatable production of complex parts with intricate designs on an industrial scale.

An example illustrating this application would be the aerospace industry where lightweight and high-strength components are critical. Parts like aircraft wing spars, fuselage sections, and engine parts can be meticulously crafted from aluminum through CNC machining. The process starts with precise programming encoding a three-dimensional design into a series of numerical commands. These guide the CNC machine’s operations to produce exact copies of the design as many times as needed.

Precision plays a crucial role in aluminum CNC machining, ensuring the accurate and consistent production of custom aluminum parts. The use of advanced CNC technology and precision machining services guarantees the high-quality and precise manufacturing of aluminum components for various industries.

Custom Solutions Offered by Aluminum CNC Machining Services

Aluminum CNC machining services offer various custom solutions to meet the unique needs of diverse businesses. These range from modifications in cutting tool paths, speed variations, axis refinements, part complexity handling, to detailed programming for complex multi-dimensional configurations. Offering tailored machining services brings several benefits to a business. Foremost are the flexibility and precision it provides an industry that demands intricate designs. It ensures the creation of end-products with higher accuracy while improving overall productivity and reducing costs.

An adept example is the automotive sector. A leading car manufacturing company was able to enhance its production rate and minimize downtime through such custom CNC solutions. Their brake pedal assembly, which required precise drilling processes, saw enhanced performance due to customized changes in spindle rotation speed and drill feed rates specific to their requirements. Therefore, these customizable machined solutions allow businesses to encounter their unique challenges head-on, paving the way towards innovation and optimized workflows.

Challenges in Aluminum CNC Machining

In the realm of Computerized Numerical Control (CNC) machining, aluminum presents a unique set of challenges. Known for its malleability and thermal conductivity, working with aluminum requires attention to detail due to its penchant for creating rough margins or uneven surfaces when machine-cut inaccurately. Equally significant is its susceptibility to heat which could deform the material and affect the end results.

- Identification of core difficulties: Aluminum’s softness can produce ragged edges or irregular shapes when not precisely cut which often leads to product rejections.

- The effect on final products: Inaccurate cutting of the metal or excessive heating during machining alters both the aesthetic and functional quality of the final output, negatively impacting customer satisfaction.

Despite these obstacles, adept service providers utilize advanced methods to combat these issues, storing aluminum at appropriate temperatures and employing precise cutting tools for exact shaping. Techniques such as high-speed machining, effective coolant strategies, and using modern, sharper tools prevent detrimental heat buildup and guarantee consistent, high-quality outputs irrespective of the inherent complexities associated with aluminum machining. These solutions are testaments to continuous innovation in addressing the intricacies of aluminum CNC machining.

Other Articles You Might Enjoy

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…

- Nickel vs. Cobalt Alloys in High-Temperature CNC Machining: A Detailed Analysis?

Nickel and Cobalt Alloys in High-Temperature CNC Machining Both Nickel and Cobalt alloys play an essential role in high-temperature CNC machining. These metal alloys are popular choices due to their…