Zinc Alloys and Aluminum: Essential Materials in CNC Machining

Metal alloys, particularly zinc and aluminum, play a crucial role in computer numerical control (CNC) machining. Zinc alloys are known for their strong resistance to corrosion, high dimensional stability, and premier casting performance. They display excellent ductility enabling them create complex shapes during the machining process. Their superior physical properties often increase productivity levels while reducing overall processing costs.

In comparison, aluminum as a material offers lightweight characteristics coupled with significant strength and durability. Its exceptional thermal conductivity, natural oxidative surface layer and capability to accommodate versatile finishes make it a preferred choice in industries like aerospace, automotive and electronics.

General Properties of Zinc Alloys

Zinc alloys boast several key properties that make them an attractive choice for use in manufacturing. Foremost among these characteristics is their excellent corrosion resistance. This can substantially enhance the longevity of products made from these metals, even when exposed to harsh environments. Another key property of zinc alloys is their lower melting point compared to many other materials. This not only allows for faster and more efficient production but also helps to minimize energy consumption during the manufacturing process.

- Corrosion Resistance: Zinc alloys exhibit a remarkable ability to withstand corrosive environments, which can lengthen the life span of the manufactured product.

- Lower Melting Point: The lower melting point of zinc alloys greatly increases the efficiency of the production process, contributing to significant energy savings.

The combined benefits of zinc alloy’s properties have seen it gain popularity in industries such as automotive, electronics, and construction.

General Properties of Aluminum

Aluminum, commonly used in CNC machining, boasts several characteristics that make it desirable for manufacturing. Foremost among these properties is its light weight; aluminum has a low density, which allows products made from this material to be lightweight but sturdy.

- Ductility: Aluminum’s impressive ductility contributes to its popularity in various industries, not least being the automotive sector. Its malleability under compression and tension allows manufacturers to easily mold it into intricate shapes or sheets with varying thickness – an advantage during machining processes.

- Thermal conductivity: High thermal conductivity is another quintessential feature of aluminum. It aids the metal to dissipate heat more quickly than many other metals, making it ideal for applications such as heat exchangers or engine components where rapid heat transfer is critical.

In sum, these attributes—light weight, ductility, and good thermal conductivity—make aluminum a prime option for diverse areas within manufacturing, particularly in tasks requiring detailed CNC machining.

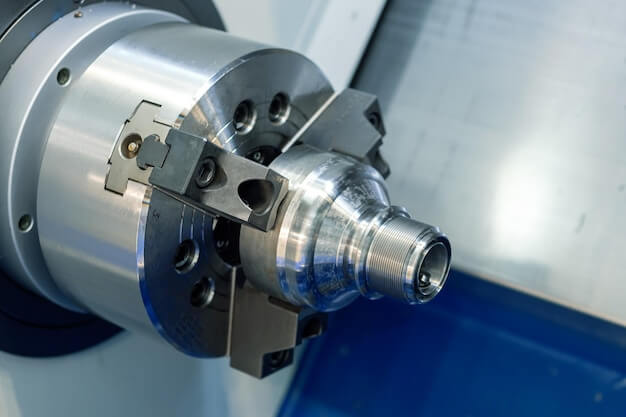

Understanding CNC Machining

CNC (Computer Numerical Control) machining is an automated manufacturing process. This process simplifies the molding and shaping of raw materials like zinc alloys or aluminum into desired forms with high precision. Unlike traditional manual machines, a computer controls the cutting tools in CNC machining.

At the heart of this system are CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. These applications help design the 3D model that will be produced and translate these designs to numerical codes that control the machine.

- CAD Software: A design tool for creating the 3D models.

- CAM Software: Translates the created 3D models into numerical code that’s understood by the machine.

- Cutting Tools: Operated by the machine as per the instructions from the programmed software.

In essence, one can imagine CNC machining like a robot sculptor who receives precise instructions from a digital blueprint and then carves out the specified form with exceptional accuracy.

Use of Zinc Alloys in CNC Machining

Zinc alloys are commonly used in CNC machining due to their excellent dimensional stability, high precision, and cost-effectiveness. They are suitable for producing intricate and detailed parts for various industries, including automotive, electronics, and consumer goods.

Use of Aluminum in CNC Machining

In the realm of manufacturing, particularly within CNC machining operations, aluminum is a frequently utilized material. Its usage can be attributed to several key advantages that this metal provides. Fundamentally, aluminum is renowned for its lightness and strength, making it suitable for parts requiring low weight but high durability. Moreover, its excellent thermal conductivity coupled with resistance to corrosion substantially contributes to enhancing the longevity and reliability of finished components.

- Ease of machinability: Aluminum’s machinability stands out as an essential attribute. The metal’s soft nature allows machine tools to cut through it swiftly and efficiently, reducing cycle times and consequently costs, without compromising precision or quality.

- Versatility: Given its malleable properties, aluminum offers superior versatility and flexibility in terms of design opportunities, enabling intricate geometries that wouldn’t be achievable with other metals. This expands design boundaries, offering manufacturers increased freedom.

- Surface finish: Owing to its fine grain structure, aluminum produces excellent surface finishes post-machining; thereby, further minimizing secondary processes such as grinding or polishing.

Numerous energy, aerospace, automotive and electronics industries take advantage of these benefits; emphasizing aluminum’s critical role in CNC machining settings.

Comparative Analysis: Zinc Alloys vs Aluminum

In contrast to aluminum, zinc has a greater chemical resistance capability and possesses its highest strength at room temperatures while aluminum exhibits its best performance when subjected to high heat. Thus, for CNC machining processes that require superior tensile strength and versatility under varying temperature conditions, zinc alloys generally outperform aluminum.

- Strengths of Zinc: Apart from excellent hardness and rigidity, zinc alloys have a low melting point which translates to less energy required during the production process. This metal also facilitates precise die-casting due to its fluid nature.

- Weaknesses of Zinc: While zinc proves efficient in numerous applications, it is not as lightweight as aluminum thus impacting the final weight of products. Also, certain zinc alloys may be prone to deformation at higher temperatures.

- Strengths of Aluminum: One key advantage of using aluminum in CNC machining includes its light weight. In addition to this, aluminum is resistant to corrosion making it suitable especially when product longevity is an object.

- Weaknesses of Aluminum: Despite these benefits, aluminum tends to lack behind in strength compared to zinc alloys. Additionally, it sometimes requires secondary operations like coating to enhance wear-resistance, indirectly increasing project costs.

In conclusion, the decision between aluminum or zinc alloy typically depends on the specific demands of the application being considered. For instance, if the project significantly values weight reduction, aluminum would come out ahead. However, where extreme resilience and cost-effectiveness are essential, zinc alloys take the win.

Industry Insights on Material Choice

In various sectors, the choice between using zinc alloys or aluminum for CNC machining significantly depends on specific industry requirements and constraints. For instance, in the automotive industry where strength and durability are paramount, zinc alloys often see more usage due to their higher tensile strength and impact resistance relative to aluminum. In contrast, industries like aerospace prefer aluminum because of its light weight nature which is critical in reducing fuel consumption.

-

The electronic sector also favors zinc alloys as they offer better electrostatic protection to sensitive components.

-

However, food industries predominantly use aluminum considering its non-toxicity and resistance to corrosion, making it ideal for items such as containers and cookwares.

-

Similarly, in construction, Aluminum stands out due to its lighter weight that makes transportation and handling easier compared to zinc alloys.

Conclusion: Zinc Alloys vs Aluminum in CNC Machining

After extensive comparison and analysis, we can affirm that zinc alloys indeed offer distinctive benefits over aluminum for CNC machining processes. Superior casting precision, longer tool life, improved surface finish quality are significant factors favoring zinc alloys. A critical technical principle is the lowered melting point of Zinc – which not only reduces manufacturing energy needs but also allows for superior formability compared to Aluminum. For example:

- Zinc’s precise casting enables the manufacture of more complex or intricate elements featuring thinner walls.

- The remarkable longevity of tools used with zinc components significantly decreases production costs over time.

- The smoothness and aesthetic appeal achieved by zinc components surpass those of aluminum due to its excellent finishing properties.

Finally, these characteristics make zinc alloys a preferred choice when high strength, tolerances, and detailed features are pivotal requirements in manufactured parts.

Other Articles You Might Enjoy

- The Functionality of Cantilever Snap Joints in CNC Machining(how does a cantilever snap joint work Rory)

The Functionality of Cantilever Snap Joints in CNC Machining The functions of cantilever clamp joints in CNC machining include several aspects: Positioning and Fixation: Cantilever clamp joints effectively position and…

- Evolving World of CNC Machining: Snap Joints to Rivets( what is a cantilever snap joint Hyman)

Exploring an industrial facility, one might encounter numerous instances where manufacturing processes utilize CNC machining. Its applications are vast and extend from the creation of titanium vs aluminum elements over…

- Exploring Bead Blasting in CNC Machining(torsion snap joint Uriah)

Bead blasting is an essential process within the broader umbrella of CNC (computer numerical control) Machining. Understanding its role and functions can provide a unique perspective on manufacturing and production,…