Introduction to Precision CNC Machining

Precision CNC machining, or Computer Numerical Control machining, is a technology that enables the design and production of complex parts with exquisite accuracy. It plays an integral role in shaping numerous industrial sectors, such as aerospace, healthcare, automotive – essentially any field where precision manufacturing is vital.

This revolutionary technique utilizes digital blueprints from 3D CAD (computer-aided design) or CAM (computer-aided manufacturing) models to direct machine tools for creating finely detailed components. Unlike conventional machining methods which require manual control, precision CNC machinery automates the entire process, resulting in highly consistent outcomes; each component produced mirrors its original design with a degree of precision unattainable by human hands.

- The technology’s significance in the manufacturing industry cannot be overstated. It offers unparalleled flexibility and scalability due to its software-driven nature,

- it drastically reduces errors and wastage caused by manual input,

- and it allows manufacturers to navigate the complexities of today’s rapidly evolving product landscapes without compromising speed or quality.

An example of this can be seen in the renewable energy sector: precision CNC machining supports the development of advanced solar panels, wind turbines, and other intricate devices designed to harness sustainable power resources more efficiently, consistently paving the way towards greener futures.

The Link Between Precision CNC Machining and Renewable Energy Solutions

Precision CNC machining plays a vital role in the development of renewable energy solutions, ensuring efficiency, accuracy, and durability. With the capability to produce detailed structures from diverse materials with impeccable precision, CNC machines are integral to creating complex components needed for efficient renewable energy systems such as wind turbines and solar panels.

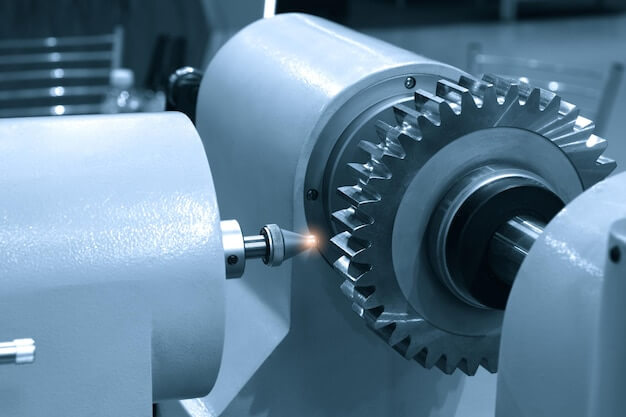

Specifically, in regard to wind turbines, the gears and rotor blades must be made with precision to operate effectively in varying weather conditions. These parts are typically produced using precision CNC machinery, which enables intricate designs to be realized while maintaining tight tolerances, thus directly impacting the efficacy of the final product. The technology also aids rapid prototyping and production, allowing for quicker implementation of renewable energy projects.

- Gears: Microscopic faults in gear teeth can lead to inefficiencies in power transmission. Precision CNC machining alleviates this by producing flawless gear profiles that maximize energy output.

- Rotor Blades: Optimal aerodynamic performance requires precision-engineered blade shapes, custom-built via CNC technologies to ensure optimal wind capture.

- Rapid Prototyping & Production: CNC machining allows fast conversion of digital designs into prototypes and finished products, hastening the development cycle for renewable energy solutions.

Benefits of using Precision CNC Machining for Advanced Renewable Energy Solutions:

- Step 1: Precision CNC machining plays a crucial role in the production of advanced renewable energy solutions, offering high-quality and high-precision manufacturing capabilities for components used in renewable energy systems.

- Step 2: The process allows for the creation of custom-designed parts with high accuracy and repeatability, meeting the specific performance requirements of renewable energy solutions.

- Step 3: To explore precision CNC machining for advanced renewable energy solutions, consider utilizing Precision CNC Machining eBook for valuable insights and considerations.

Applications of Precision CNC Machining in Renewable Energy

The diverse application of precision CNC machining is tangible in the renewable energy sector, transforming production techniques and enhancing efficiency. In solar power applications, for instance, its role cannot be overlooked in photovoltaic (PV) panel production. It aids in creating high-precision PV cells, which are essential components consolidated to form a complete solar panel. This level of precision significantly increases the performance and lifespan of such panels.

- Solar Power: In creating specific parts like inverters or micro-inverters where necessary accuracy and quality are mandatory, it has turned out to be an invaluable tool. Also, solar trackers crafted through precision machining ensure optimal exposure to sun rays over extended periods.

- Wind Energy: The wind energy sector highly relies on precision CNC machining, especially in fabricating turbine components. Blades manufactured with matching fidelity enhance their aerodynamic properties, amplifying the turbine’s overall output. Additionally, it offers possibilities in generating custom-built pieces tailored according to unique specifications for greater system adaptability.

- Other Forms: Techniques employed by precision CNC machines have found productive use in producing equipment for hydropower and geothermal energy forms as well. For example, precise manufacturing of turbines and generators usually used in hydroelectric power plants or drilling heads used in harnessing geothermal power.

These instances underline the insurmountable significance of precision CNC machining in fostering capacity development in renewables and driving the push towards cleaner and sustainable global energy solutions.

Future Prospects of Precision CNC Machining in Renewable Energy Sector

The escalating demand for renewable energy solutions signifies a broad horizon for precision CNC machining. Innovations are anticipated in the realm of materials, such as more resilient composite inputs and biodegradable alternatives, offering enhanced durability while aligning with environmental sustainability. For instance:

- Novel alloys can withstand higher stresses and diffuse heat effectively, fortifying the longevity of wind turbine components.

- Sophisticated microfabrication techniques can enable intricate design patterns on solar cells to maximize light absorption.

Such advancements directly impact the speed of energy generation by boosting machine efficiency and performance. Moreover, automation upgrades integrating smart sensors and artificial intelligence algorithms could refine process control, minimizing errors and waste products during production lines. Consequently, this will also enhance the sustainability of renewable energy productions, leading to greener processes as well as more reliable energy resources. Exploring these trends, we recognize that precision CNC machining will play a crucial role in fostering advanced renewable energy capabilities.

Conclusion: Why Precision CNC Machining Matters for Renewable Energy

In conclusion, precision CNC machining plays a pivotal role in the advancement of renewable energy solutions. As discussed throughout this article, it lends efficiency, reliability and high-quality production to the sector. The correlation between precision CNC machining and advanced renewable energy solutions isn’t solely about component manufacturing but more importantly, how accurate, rapid, and repeatable these processes are which significantly reduce waste, cost, and time.

This underlines its vitality in creating intricate components needed for complex renewable energy systems such as wind turbines, photovoltaic cells or bioenergy convertors with utmost precision and minimum errors. Its metallurgical capabilities, combined with computerized controls provide limitless potential in terms of scalability and complexity that modern renewable energy infrastructure demands.

- Precision CNC machining guarantees near-perfect accuracy, reducing margin of error and wastage.

- It provides flexibility and diversity in material utilisation, fostering innovation.

- CNC automation aids large-scale productions and fuels the cost-effectiveness of renewable energy solutions.

To wrap up, the nexus between precision CNC machining and renewable energy is one of symbiotic growth and progress driven by technology.

Other Articles You Might Enjoy

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…