CNC Machining with Plastics: POM vs. PEEK – Which is More Efficient?

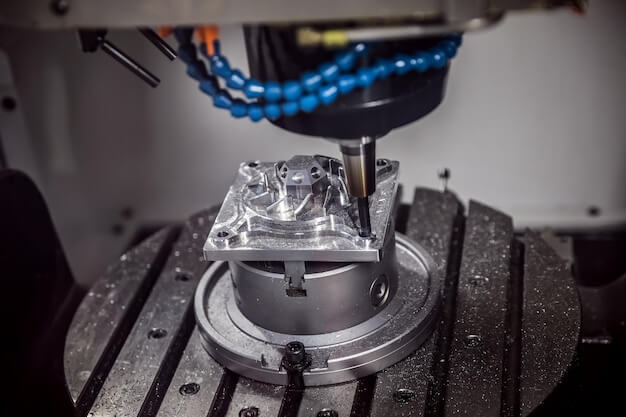

CNC Machining in Manufacturing and the Utilization of Plastics In today’s advanced manufacturing industry, CNC (Computer Numerical Control) machining continues to play an integral role. This technology helps in creating parts and pieces with a high level of precision and consistency, making it indispensable for industries demanding accuracy such as aerospace, automotive, medical, and more. […]

The Future of Beryllium Copper in CNC Machining: Is It Still the Go-To for Electrical Connectors?

The Significance of Beryllium Copper in CNC Machining and Electrical Connectors Beryllium Copper, commonly referred to as BeCu, is a copper alloy with 0.5-3% beryllium that exhibits superior thermal conductivity, resistance to galling, high strength, and excellent electrical conductivity. This unique combination of properties makes it an ideal choice for numerous complex components, especially those […]

High-Speed Steel vs. Carbide in CNC Tooling: Life Span and Performance Showdown?

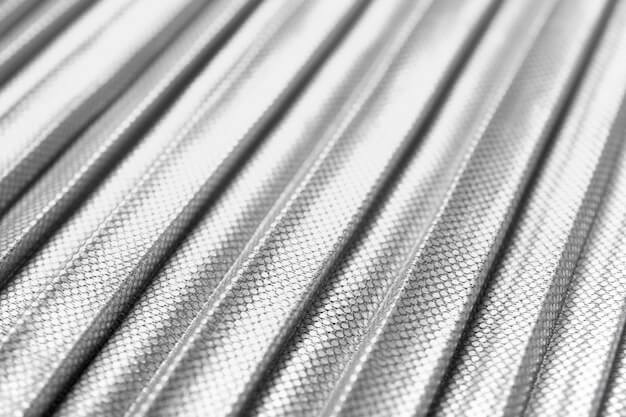

Introduction to High-Speed Steel and Carbide in CNC Tooling In the world of Computer Numerical Control (CNC) tooling, two materials have emerged as key players: high-speed steel (HSS) and carbide. HSS, which contains elements such as tungsten, molybdenum, vanadium, and chromium, is known for its versatility and toughness while carbide, a composite of carbide particles […]

Molybdenum Alloys in Precision CNC Machining: Applications and Advantages?

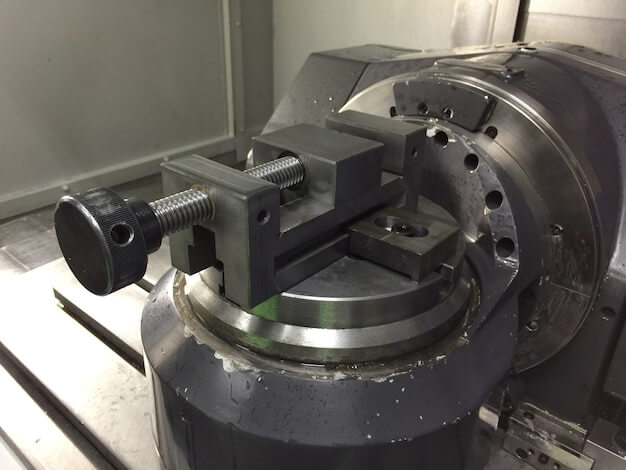

Molybdenum Alloys and Precision CNC Machining: An Introduction Molybdenum alloys, known for their high melting point and thermal conductivity, are integral to the world of precision Computer Numerical Control (CNC) machining. CNC machining is a subtractive production method that uses computer-controlled machines to remove material from workpieces and fashion them into desired parts. Designed with […]

The Advantages of Using LSR (Liquid Silicone Rubber) in CNC Prototyping and Production?

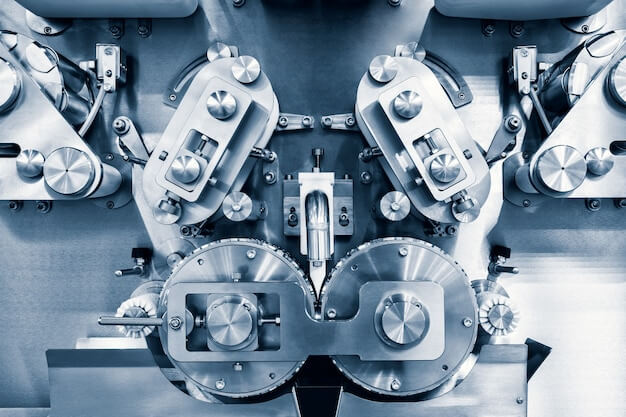

Introduction to LSR in CNC Prototyping and Production The utilization of Liquid Silicone Rubber (LSR) in CNC prototyping and production has been growing exponentially due to its numerous advantages. For those unfamiliar with technical terminologies, a simple understanding is that LSR is a type of thermosetting elastomer with high versatility and durability used along with […]

Brass vs. Bronze in CNC Machining: Which Offers Better Precision and Durability?

CNC Machining and Material Selection CNC (Computer Numerical Control) machining is a digitally automated process used in manufacturing sectors where computers control machine tools. This intricate technology enables high precision, consistency, and scalability in producing complex shapes that are difficult to manufacture by manual intervention. Consequently, material selection becomes pivotal as it directly impacts the […]

The Role of Copper Alloys in CNC Machining: C36000 vs. C93200 Comparison?

Introduction to Copper Alloys in CNC Machining CNC (Computer Numeric Control) machining holds critical importance in various industries, including automobile, aerospace and electronics manufacturing. It constitutes an automated control of machining tools that cut, shape, or finish a workpiece by following digitally-encoded instructions. One of the materials extensively used in this procedure is copper alloys. […]

Choosing Between Zinc and Aluminum Alloys for CNC Machining: Cost-Effectiveness and Performance?

CNC Machining and Zinc & Aluminum Alloys: An Overview Computer Numerical Control (CNC) machining is a crucial process used in the manufacturing sector that entails utilizing pre-programmed computer software dictating the machinery’s movements—effectively controlling a range of machineries from grinders, mills to lathes. This level of automation enables high precision, complex parts production more accurately […]

The Viability of Magnesium Alloys in Lightweight CNC Machined Components: Benefits and Challenges?

Introduction to Magnesium Alloys and CNC Machining Magnesium alloys, due to their lightweight nature coupled with superior mechanical properties, have been gaining prominence in various manufacturing industries. In particular, the use of these alloys in Computer Numerical Control (CNC) machining—a computer-aided process enabling precise control of a variety of complex machinery—has emerged as a leading […]

The Advantages of Using Silicon Nitride in High-Speed CNC Machining Applications?

Introduction to CNC Machining and Silicon Nitride In high-speed Computer Numerical Control (CNC) applications, the use of ideal materials is critical for optimum performance. One such material that has proven beneficial in this context is silicon nitride. CNC machining refers to a process used in manufacturing sectors that involves the use of computers to control […]

Exploring the Potential of Inconel in High-Temperature CNC Applications: Is It Worth the Investment?

Exploring the Potential of Inconel in High-Temperature CNC Applications In manufacturing industries, one material that has garnered significant attention for its high-temperature properties is Inconel. This alloy, primarily made up of Nickel and Chromium, exhibits excellent resistance against oxidation and corrosion, even at extremely high temperatures. Its outstanding strength and toughness make it a suitable […]

CNC Machining: Aluminum 2024 vs. 6063 – Which Alloy Performs Better?

Introduction: Aluminum 2024 vs. 6063 Alloys in CNC Machining The process of CNC machining requires careful selection of the appropriate material to ensure optimized performance and product longevity. Key among these considerations are aluminum alloys, specifically 2024 and 6063. The 2024 alloy, composed mostly of aluminum, copper, manganese and small percentages of other compounds, is […]