Introduction to CNC Machining and Inconel

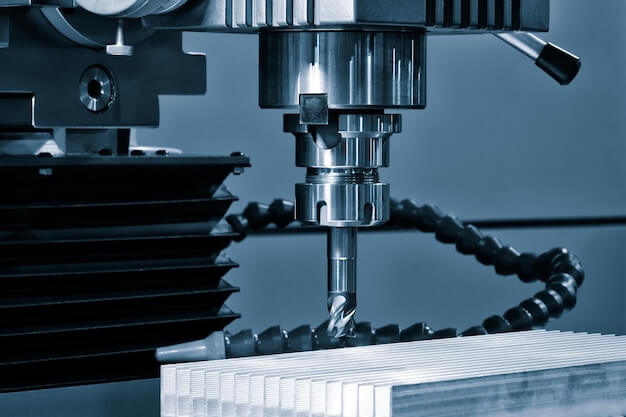

The world of manufacturing has revolutionized significantly with the utilization of CNC (Computer Numerical Control) machining. This innovative technology enables precision-controlled automated devices to complete tasks with incredible detail, high-speed efficiency, and minimal human intervention. Simply put, CNC machines are programmed to follow computer-aided design (CAD) models for shaping raw materials into desired end-products.

When considering materials that embody extreme durability under harsh conditions, nothing surpasses the profound characteristics of a superalloy known as Inconel. Designed from a unique blend of Nickel-Chromium, Inconel boasts an exceptional resistance to oxidation and corrosion, thus making it the go-to material choice in industries exposed to severe thermal environments. Moreover:

- Its stability at elevated temperatures safeguards critical mechanical properties when most metals capitulate.

- It exhibits remarkable strength and toughness in cryogenic applications down to -423°F (-253°C).

- Its ability to withstand high pressure and radiation makes it indispensable in nuclear operations

.

Advanced Techniques in CNC Machining with Inconel

In the realm of advanced manufacturing processes, working with superalloys like Inconel presents unique challenges due to its hardness, propensity for work hardening, and heat generation during machining. These inherent properties necessitate the application of sophisticated techniques in computer numerical control (CNC) machining to ensure precision and efficiency. Inconel’s extreme hardness implies that it frequently dulls cutting tools, leading to increased production time and costs. Moreover, it has a tendency to undergo work hardening, which means it gets stronger as it’s deformed — making repetitive cutting tasks exceedingly difficult.

- Additionally, Inconel generates immense amounts of heat when machined, exacerbating these issues while risking tool damage and compromising product quality.

- To counteract these complications, advanced methods such as high-speed machining, cryogenic machining, or using ceramic inserts can be employed to extend tool life, enhance surface finish, and maintain machining accuracy.

This underlines the growing demand for state-of-the-art CNC techniques in dealing with formidable materials like Inconel, particularly in demanding sectors such as aerospace and energy where high-temperature resistance is critically required.

Specific Advanced Technique: Optimized Tool Paths

Optimized tool paths are a critical advanced technique in CNC machining for working with Inconel in high-temperature applications. By optimizing tool paths, manufacturers can minimize tool wear, reduce machining time, and enhance surface finish quality when working with the challenging properties of Inconel. This technique involves strategically planning the movement of cutting tools to maximize efficiency and precision in machining complex components from Inconel for high-temperature applications.

High-Speed Machining in CNC Operations with Inconel

In the realm of Computer Numeric Control (CNC) machining, high-speed machining has emerged as a valuable technique to handle materials like Inconel, ideally used for high-temperature applications. High-speed machining plays an essential role due to its inherent benefits such as reducing heat generation and improving surface finish by running at accelerated speeds and leveraging lower depths of cut. Managing Inconel, known for its hardness and heat resistance, becomes significantly manageable using this method.

- Avoids Heat Accumulation: As faster cutting speeds are attained while machining Inconel, less heat is produced, preventing deformation or alteration of the material’s properties.

- Reduces Material Hardening: Lower depths of cut mean reduced tool-material contact period thus decreasing the chance of work hardening, making further machining simpler.

- Enhances Surface Finish: High-speed machining’s rapid movements help produce smoother surfaces, enhancing the final look and function of the manufactured parts. This also reduces post-machining refinement activities.

To illustrate, consider a scenario where a substantial Inconel component needs machining. With traditional techniques, much time would be spent managing heat and ensuring the material doesn’t become overly hardened. However, employing high-speed machining enables faster production rate with improved part longevity and fewer rejects due to superior surface quality.

Using Advanced Cooling Methods in CNC Machining

In Computer Numeric Control (CNC) machining, maintaining an optimal temperature during operation is essential to ensure precision and prevent damage to machines and components. Working with materials like Inconel that are utilized for high-temperature applications brings the necessity of advanced cooling techniques. Such techniques include:

- Flooding: This technique involves a torrential flood of coolant aimed at the cutting tool and workpiece. It effectively draws away heat given off during the machining process.

- Misting: A method where a mixture of air and coolant forms a mist that serves as a thermal conductor between the machine and the work material.

- Cryogenic Machining: This supercooling method immerses the machining area in ultra-low temperatures using substances like liquid nitrogen. This prevents heat formation in the first place by reducing the temperature drastically.

The application of these methods can help maintain the temperature while processing Inconel parts, increasing efficiency and productivity, ultimately resulting in improved output quality.

Choosing the Right Cutting Tools for Inconel

When machining Inconel, it is critical to select cutting tools that are able to withstand and perform efficiently under high-temperature conditions. Given the material’s hardness and heat resistance, typical conventional tool steels would wear quickly, compromising the quality of workmanship as well as production timelines. Employing advanced materials such as ceramics or cubic boron nitride (CBN) in your cutting tools can remarkably elevate performance during Inconel machining processes.

- Ceramics: Ceramic cutters provide superior heat resistance and hardness making them an excellent choice when working with Inconel. They are resistant to wear, allowing for longer operation periods without noticeable degradation in performance.

- Cubic Boron Nitride (CBN): CBN cutters, known for their extreme hardness and thermal stability, offer significant advantages while machining Inconel. These properties help maintain sharp tool edges even at elevated temperatures, hence ensuring precise cuts.

Thus, choosing appropriate cutting tools not only impacts the longevity and efficiency of your machinery but also directly influences the quality of the finished product while working with robust materials like Inconel.

Importance of Operator Expertise in Handling Inconel

The precision involved in manufacturing high-temperature applications using Inconel necessitates the need for well-trained and skilled operators handling Computer Numerical Control (CNC) machines. As a superalloy, Inconel’s complex properties such as its resistance to deformation at high temperatures require a deep understanding of equipment capabilities. An operator’s extensive knowledge about the operational factors related to the alloy can significantly influence the quality of the output.

- An experienced operator will have adept analytical skills needed to devise effective machining strategies tailored per job;

- They can quickly identify and troubleshoot potential issues during the production process;

- Furthermore, they are able to optimize machine settings based on the specific characteristics of Inconel, ensuring minimal wear on the cutting tool while maintaining optimum feed rate, improving overall efficiency and productivity.

In conclusion, the role of an expert CNC machine operator is crucial when working with specialized materials like Inconel in order to guarantee superior-quality end products that meet high-temperature applications’ stringent requirements.

Conclusion: Emphasizing the Benefits of Advanced Techniques in CNC Machining with Inconel

The benefits of employing advanced techniques in CNC machining with Inconel are undeniable and manifold. These techniques have revolutionized how we handle high-temperature applications, introducing a level of accuracy and efficiency previously unattainable. Operations that would have taken hours now take minutes, reducing production times and increasing output.

- The precise control afforded by these methods cuts down on waste significantly, leading to cost savings and less environmental impact.

- Additionally, their ability to cope with complex geometries and tough materials such as Inconel without sacrificing precision or quality is truly game-changing.

- This transformative technology isn’t static either; advancements continue to emerge, promising even more improved processes in the future.

We look forward to integrating further innovations into our work processes in anticipation of enhanced productivity, reduced costs, and superior product quality. Indeed, the potential held by advanced techniques in CNC machining with Inconel appears boundless.

Other Articles You Might Enjoy

- Exploring Bead Blasting in CNC Machining(spot welding Elvira)

Bead blasting is a prominent finishing process often applied in Computer Numerical Control (CNC) machining. This article aims to explore bead blasting, its significance, and how it's produced within the…

- Innovative CNC Machining for Advanced Aerospace Materials

Innovative CNC Machining for Advanced Aerospace Materials CNC machining, or computer numerical control machining, is a process utilized in the manufacturing sector that involves the use of computers to operate…

- Evaluating the Use of Beryllium Copper in CNC Machining for Aerospace Applications: Is It Safe and Effective?

Introduction: Beryllium Copper's Role in CNC Machining for Aerospace Applications The advanced manufacturing industry, especially aerospace where safety and effectiveness are of prime importance, heavily relies on robust materials to…