Introduction to Brass Precision Prototyping and CNC Machining

In the realm of prototyping, brass precision and Computer Numeric Control (CNC) machining play significant roles. Brass precision prototyping is a process where highly accurate components are manufactured using brass metals, renowned for their strength, machinability, and resistance to corrosion. This method provides an efficient means of creating complex parts without the cost or time required for traditional manufacturing.

On the other hand, CNC machining’s relevance in prototyping cannot be overstated. It includes drilling, milling, and turning processes carried out by computer-controlled devices, ensuring increased accuracy, consistency, and speed of production. Moreover:

- CNC machines can work on various materials besides brass, making them versatile.

- They facilitate rapid prototyping leading to quicker product launches.

- Such machines considerably cut down human error and material wastage, improving overall efficiency of the process.

Thus, leveraging these technologies can lead to quick turn machining solutions, allowing companies to accelerate design cycles while maintaining high quality standards.

Basics of Brass Precision Prototyping

Precision prototyping refers to the design process in which a physical model or ‘prototype’ of a product is created with high precision, typically using Computer Numerical Control (CNC) machining. In this approach, brass plays a vital role due to its unique properties. As a material, brass exhibits excellent machinability, durability and corrosion resistance – attributes that are critical in precision manufacturing. This allows for extreme accuracy in creating complex shapes and designs, thus making it an ideal choice for precision prototyping.

- Concept of precision prototyping: The goal of precision prototyping is to create particular parts with great detail and exactness, often as part of detailed modeling processes or advanced manufacturing lines.

- The significance of brass: With its superior machinability and hard-wearing nature, brass affords manufacturers the capacity to ensure precise, robust prototypes whilst achieving speedy project turnarounds. This makes brass an integral component in providing quick turn machining solutions.

Leveraging CNC Machining for Brass Precision Prototyping

Brass precision prototyping leverages CNC machining to provide quick turn machining solutions for various industries. The malleability, corrosion resistance, and excellent electrical conductivity of brass make it an ideal material for precision prototyping, and CNC machining ensures the production of high-quality, custom-designed components.

Advantages of Brass Precision Prototyping Using CNC Technology

Brass precision prototyping leverages Computer Numerical Control (CNC) technology to provide a plethora of benefits. These include:

- High Accuracy: Through the use of advanced software control system, CNC machining ensures precise and consistent outputs, which is pivotal when working with delicate brass components.

- Increased Efficiency: CNC machines operate around the clock, leading to faster production times without compromising on quality.

- Flexibility: They can easily be reprogrammed to produce different parts, allowing for cost-effective small batch production.

- Safety: As they are entirely automated, CNC machines reduce the risk of operator injury.

In terms of efficiency in particular, using CNC technology for brass precision prototyping proves transformational. With conventional methods, a prototype could take days or even weeks to complete – however, with CNC machining, these timelines are drastically reduced. For industries that prize speed to market, this value cannot be overstated. Furthermore, the outstanding accuracy associated with this method lends itself perfectly to the intricate designs often required in brass precision prototyping, significantly decreasing the incidence of costly errors. On such a backdrop, it becomes evident why more and more industries are opting for CNC-based brass precision prototyping.

The Process of Brass Precision Prototyping with CNC Machining

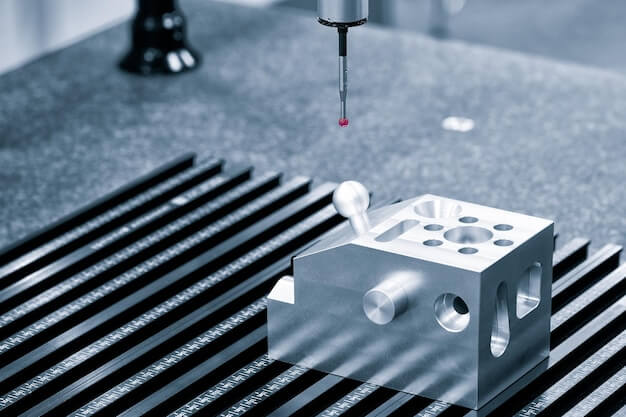

The process of brass precision prototyping using Computer Numerical Control (CNC) machining is a sophisticated operation that includes unique stages to bring prototypes into fruition. It begins with developing an accurate digital blueprint derived from CAD software, which effectively guides the machine for flawless creation. This digital model gives an exact dimension and structure, eliminating guesswork entirely.

Cutting paths are then regulated via CAM software, determining how the device will maneuver to achieve desired shapes without any discrepancies. These cutting routes utilize minimum material yet yield optimal output. Post this, as per instructions passed by CAD-CAM integration, the chosen brass material undergoes some specific operations including drilling, milling, or turning on the appliance.

Last but not least, once machining is done, the operator carries out post-processing tasks like inspection for quality control purposes.This ensures smoothness ,high-resolution finishing and also verifies if precise specifications have been adhered to.

Addressing Common Misconceptions or Problems Facing Brass Precision Prototyping

In the realm of brass precision prototyping, technical enthusiasts and users often encounter several misconceptions and hurdles. The common misconception is that CNC machining for quick turn solutions compromises on the quality owing to its speedy operation – however, this is far from true. Quick-turn CNC Machining ensures consistency in output while speeding up production timelines, thereby not sacrificing quality.

Potential pain points before venturing into Brass Precision prototyping include apprehension about programming knowledge needed, cost-effectiveness, time management, and post-production cleanup. To allay these concerns:

- Understand that learning CNC programming can be a straightforward task with suitable guidance and tools.

- Consider the fact that automated machinery reduces labor costs and enhances productivity; thus, being cost-effective in the long run.

- Acknowledge that using CNC machines deliver quicker results reducing delayed delivery issues, ensuring effective time management.

- The modern CNC Machines come equipped with advanced features like automatic chip removal systems enabling hassle-free cleanup process.

Case Study: Effectiveness of Brass Precision Prototyping and CNC Technology

In a practical demonstration of the power of brass precision prototyping combined with CNC technology, a reputed aerospace company was faced with a pressing schedule for producing complex precision parts. They decided to approach the challenge using brass as their prototype material coupled with CNC machining. This decision came with multiple success factors.

- Rapid production speed: With the precision capabilities of CNC machines, the previously time-consuming process of manual machining was eliminated, enabling quick turn machining solutions. The result was highly accurate prototypes in half the expected duration.

- Cost-effectiveness: As brass is relatively affordable compared to other metals, significant cost reductions were observed in both raw materials and subsequent processing costs.

- Error minimization: CNC technologies not only improved speed but also drastically reduced errors due to its ability to replicate designs with high accuracy consistently. This resulted in fewer retrials and reworks, thus saving the company on resources and time.

- Customer satisfaction: Leveraging brass precision prototyping and CNC technology allowed the company to meet strict deadlines while delivering quality products, ultimately boosting customer satisfaction rates.

This case study demonstrates that employing brass precision prototyping along with CNC technology provides an efficient, economical, and superior solution for industries requiring quick turnaround times and critical-tolerance components.

Conclusion

In summary, the fusion of brass precision prototyping and CNC machining has significantly revolutionized quick turn machining solutions. This combination brings about improved efficiency, shorter turnaround times, remarkable accuracy, and cost-effectiveness in manufacturing processes. The result is a seamless transition from conceptual designs to physical prototypes, with minimal errors, even on intricate details.

The impact it has had on quick turn machining solutions cannot be overstated as this innovation allows for faster production rates and high-volume outputs without compromising quality. Ultimately, by leveraging the strengths of both brass precision prototyping and computer-controlled technology, manufacturers are able to meet the ever-growing demands of diverse industries at incredibly fast pace.

Other Articles You Might Enjoy

- Elevating Precision Standards through Chamfer in CNC Machining

1. Introduction: The Pursuit of Unparalleled Precision In the realm of CNC machining, precision is paramount. This section introduces the article by exploring the significance of precision in manufacturing and…

- Precision CNC Machining: Brass vs. Aluminum - Which Material Suits Your Project?

Precision CNC Machining: Overview and Material Selection CNC machining, an acronym for Computer Numerical Control machining, is a process in the manufacturing sector that involves the use of computers to…

- Brass CNC Machining: The Advantages of Using Brass in Custom Metal Fabrication and Prototyping

Introduction to Brass CNC Machining and Its Importance in Custom Metal Fabrication and Prototyping CNC machining, a digitally-powered manufacturing process that deploys pre-programmed computer software to manipulate tools' movement and…

- Choosing Between Brass C36000 and C37000 for Precision CNC Machining

Introduction to Precision CNC Machining and its Significance in Manufacturing Precision CNC machining is a manufacturing process that utilizes computerized controls for operating various machine tools such as lathes, mills,…

- Precision Prowess: Unveiling the Advantages of China CNC Machining

1. Introduction: The Role of Precision in Manufacturing Excellence In this introductory section, we delve into the critical role that precision plays in manufacturing and set the stage for an…

- Revolutionizing CNC Machining for Complex Aerospace Assemblies

Introduction to CNC Machining in Aerospace Assemblies Computer Numerical Control (CNC) machining represents a significant technological development playing a notable role in the creation of complex aerospace assemblies. CNC machining…