CNC machining is a marvel of modern engineering, enabling the production of intricate parts with high precision. But behind every perfectly crafted piece lies the unsung hero of the process: the part drawing. This document, though often overlooked, is the cornerstone of CNC programming. It’s a detailed map that guides the CNC machine in shaping raw materials into functional components. Let’s dive into the fascinating world of CNC machining part drawings and uncover how they bridge the gap between design and production.

The Role of Part Drawings in CNC Programming

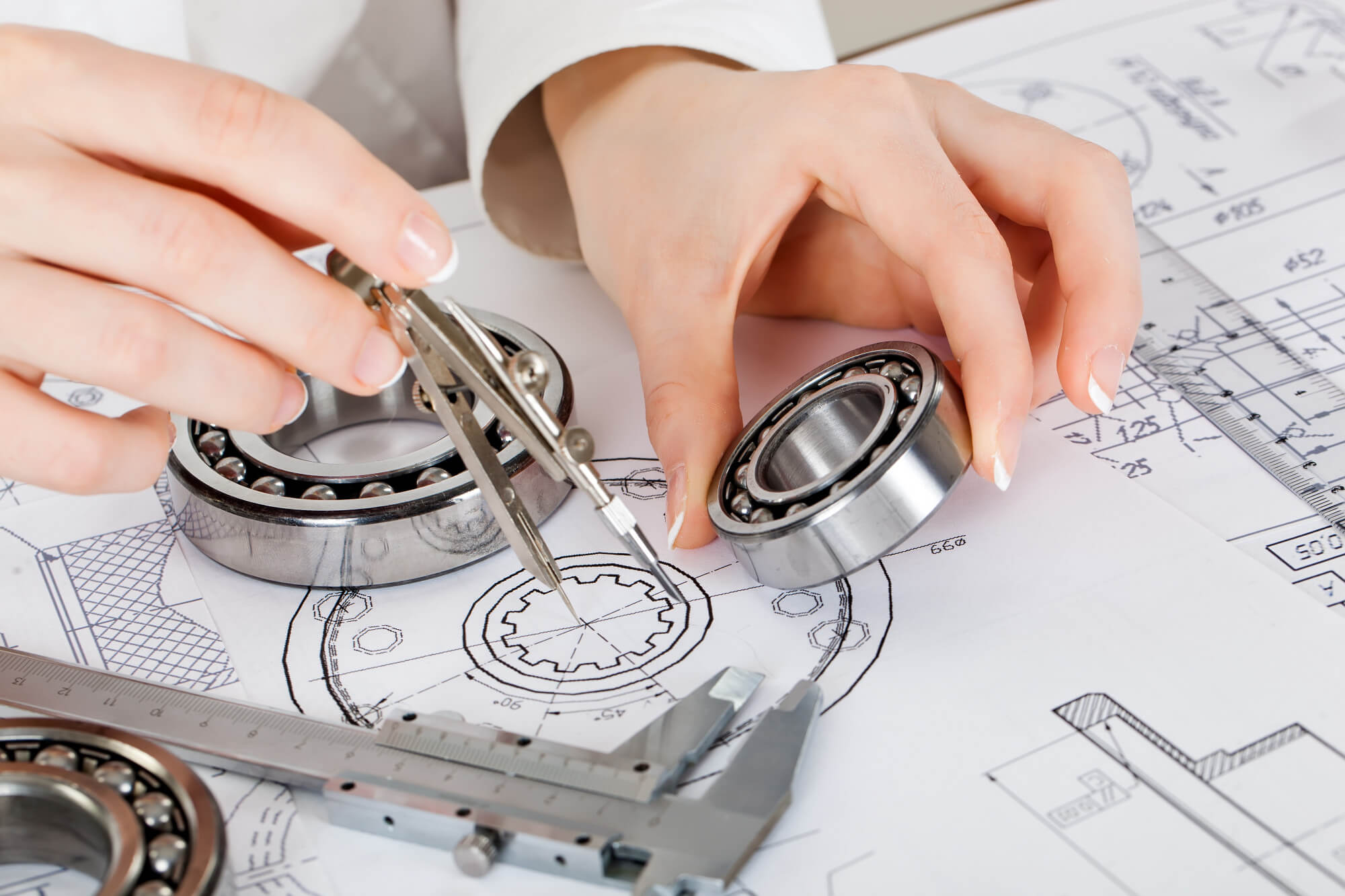

Part drawings are the primary source of information for CNC programmers. These drawings illustrate the shape, dimensions, tolerances, surface quality, and other critical specifications of the workpiece. For complex parts, multiple drawings are often required, each providing different views, sectional views, and detailed segments of the part. Programmers meticulously calculate all the drawing data and isolate the relevant information needed for developing specific programs.

However, traditional sketching methods sometimes fail to reflect the actual CNC manufacturing process, merely conveying the designer’s intentions. While technically correct, these drawings can be challenging for programmers to interpret and translate into CNC values. Hence, the traditional boundaries between design, drafting, and CNC programming must be blurred in a CAD/CAM environment. This integration helps programmers understand the designer’s intent and vice versa, ensuring a coherent and efficient design-to-production process.

Engineering Drawing Bill of Materials (BoM)

An engineering drawing’s Bill of Materials (BoM) is a critical component that gathers all descriptive information related to the specific part. Though the format may vary across companies, depending on production types and internal standards, it typically appears as a rectangular box divided into several small cells located in one corner of the drawing. The BoM usually includes part names, part numbers, material data, revisions, and special instructions. This data is essential for CNC programming and can be used in program files for cross-referencing.

Dimensioning and Tolerancing

Dimensions on part drawings can be in imperial or metric units. Individual dimensions might reference specific datum points or be measured as continuous dimensions from a previous dimension. Typically, both types are mixed within the same drawing. When writing programs, converting all continuous (or incremental) dimensions to reference (or absolute) dimensions is more convenient. Most CNC programmers benefit from absolute dimensioning, which simplifies program changes by requiring modifications in only one place.

In contrast, incremental dimensioning requires multiple changes for program adjustments. Figures 6-2 and 6-3 illustrate these differences, with Figure 6-2 using absolute dimensions and Figure 6-3 using incremental dimensions. While incremental programming is appropriate for certain subprograms, absolute dimensioning is preferred for its ease of editing within CNC systems.

Decimal and Fractional Dimensions

Old drawings using imperial units often contain fractional or decimal dimensions. Fractional dimensions indicate less critical tolerances (e.g., nominal size ±0.03 in), with more decimal places representing tighter tolerances. Since fractional dimensions aren’t ISO-standard, they must be converted to decimals. The number of decimal places in the program depends on the controller’s minimum increment. For instance, a dimension of 3 might be written as 3.75, and a dimension of 5 might be written as 5.1718, rounded to the nearest feasible value. Many companies have upgraded their design standards to the ISO system, adhering strictly to CNC dimensioning principles, making metric drawings more practical.

Potential Issues with CAD Software

Improper use of CAD software (e.g., AutoCAD) can result in dimensioning issues. Some designers do not change the default decimal places, leading to four decimal places (imperial) or three decimal places (metric) for every dimension. This practice should be avoided, as it’s better to specify all required tolerances clearly, potentially using Geometric Dimensioning and Tolerancing (GD&T) standards. GD&T establishes the relationship between two or more features on a drawing, such as defining the coaxiality of holes and surfaces. Before GD&T’s widespread use, drawings often included various instructions and information, which might not comply with international ISO standards.

Angular Dimensions and Tolerances

According to modern standards, angular dimensions should be represented in decimal degrees (DD). Older drawings might use degrees, minutes, and seconds (DMS or D-M-S). The conversion between the two is as follows:

DD= D + M/60 + S/3600

Where:

- DD = decimal degrees,

- D = degrees,

- M = minutes,

- S = seconds.

Tolerances in CNC Machining

To enhance machining precision, many part dimensions specify acceptable deviations from the nominal size. For example, a tolerance of +0.001/-0.000 inches in the imperial system differs from +0.1/-0.0 mm in the metric system. Such critical dimensions are paramount in CNC machining and must be adhered to strictly. CNC operators often ensure that part dimensions stay within tolerance, provided the program is correct. However, CNC programmers can facilitate the operator’s work by making thoughtful decisions during programming.

Consider a hole specified as Ø75+0.00/-0.05 mm. The program could set the upper limit at 75.0 mm, the lower limit at 74.95 mm, or a midpoint at 74.975 mm. While mathematically sound, a creative CNC programmer might also consider tool wear. Over time, tool edges wear out, necessitating manual adjustments. By programming the lower limit for an external dimension or the upper limit for an internal dimension, tool wear remains within tolerance, reducing the frequency of manual adjustments.

Surface Roughness

High-precision parts often require a specified surface finish quality, indicated on the drawing. In the imperial system, surface roughness is measured in pin (1 pin = 0.000001 inch), while in the metric system, it’s measured in μm (1 μm = 0.001 mm). Drawings might use symbols like those in Figure 6-4 to denote surface roughness requirements. Factors affecting surface quality include spindle speed, feed rate, tool radius, and material cut allowance. Generally, larger tool radii and smaller feed rates yield better surface quality, although at the cost of longer cycle times. Post-processing operations like grinding or honing can offset this.

Part Drawing Revisions

Part drawings also document engineering changes, known as revisions, with specific dates (Figure 6-5). Designers use reference numbers or letters to indicate these changes, typically showing both the current and new values. For program development, only the latest revision is crucial, ensuring the program reflects the current design. Programmers often back up programs corresponding to drawing revisions to prevent misunderstandings.

Special Instructions

Many drawings include special instructions and notes, which are crucial for CNC programming but can’t be represented by standard drawing symbols. These instructions might specify reference surfaces or diameters, indicating the final dimensions post-grinding allowance. Additionally, assembly-related instructions might denote holes requiring drilling or threading during assembly rather than during initial machining. Ignoring these instructions can result in part rejection.

Instructions are often indicated by pointers with arrows, pointing to the relevant feature on the drawing. For example, a pointer to a hole might include the note:

\diameter 12 – Ream 2 holes – Depth 20

This indicates two 12mm diameter holes should be reamed to a depth of 20mm.

Table: Example of a Part Drawing BoM

Here’s an example of what an Engineering Drawing BoM might look like:

| Item No. | Part Name | Material | Drawing No. | Revision | Date |

|---|---|---|---|---|---|

| 1 | Shaft | Steel | 1001 | R2 | 2024-01-15 |

| 2 | Sleeve | Aluminum | 1002 | R1 | 2024-01-12 |

| 3 | Washer | Brass | 1003 | R3 | 2024-01-18 |

| 4 | Bolt | Steel | 1004 | R2 | 2024-01-10 |

This table collects all relevant descriptive information about the part, essential for both CNC programming and cross-referencing in program files.

In the intricate dance of CNC machining, part drawings play a vital role. They serve as the bridge between the designer’s vision and the machinist’s execution, ensuring that every part produced meets the precise standards required. By understanding and effectively utilizing these drawings, CNC programmers and operators can achieve remarkable efficiency and precision, breaking down the barriers between design and production.

Other Articles You Might Enjoy

- Bronze Rivet Technology in CNC Machining

Bronze type that can process Rivet Phosphor Bronze Characteristics: High strength, excellent wear resistance, good elasticity. Applications: Springs, bearings, and parts requiring high wear resistance and elasticity. Tin Bronze Characteristics:…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Custom CNC Machining: Tailoring Solutions to Unique Engineering Challenges?

Introduction to Custom CNC Machining In the manufacturing world, innovations continually emerge and challenge traditional production methodologies. A significant game-changer has been Computer Numerical Control (CNC) machining — a process…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Rivets Production and Tack Welding in CNC Machining(chamfer Lesley)

Computer Numerical Control (CNC) machining is an advanced manufacturing process that uses pre-programmed computer software for controlling the tools' movement to create a specific product. The movement may include procedures…

- Precision CNC Machining for High-Performance Industrial Machinery

Precision CNC Machining for High-Performance Industrial Machinery The process of Precision CNC (Computer Numerical Control) machining is at the core of manufacturing high-performance industrial machinery. This technique leverages a computer's…