Analysis of the Structural Manufacturability of Parts

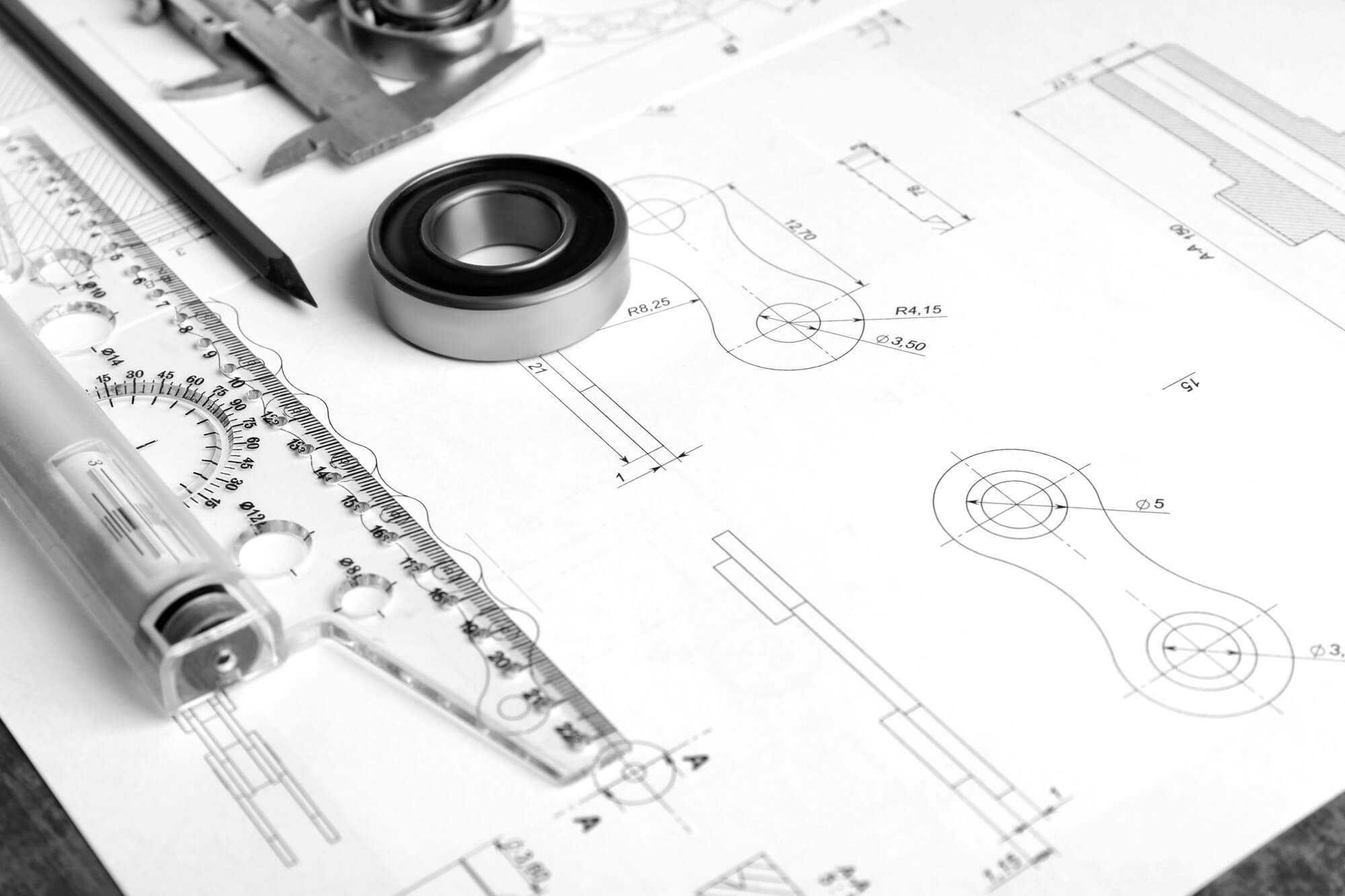

Understanding Structural Manufacturability Structural manufacturability of parts refers to the feasibility and economic efficiency of manufacturing the designed parts while

Understanding Structural Manufacturability Structural manufacturability of parts refers to the feasibility and economic efficiency of manufacturing the designed parts while

CNC machining is all about precision and efficiency, especially when it comes to navigating sharp corners and changing directions. When

Controlling the feed rate is one of the most crucial aspects of programming CNC machines. The feed rate determines how

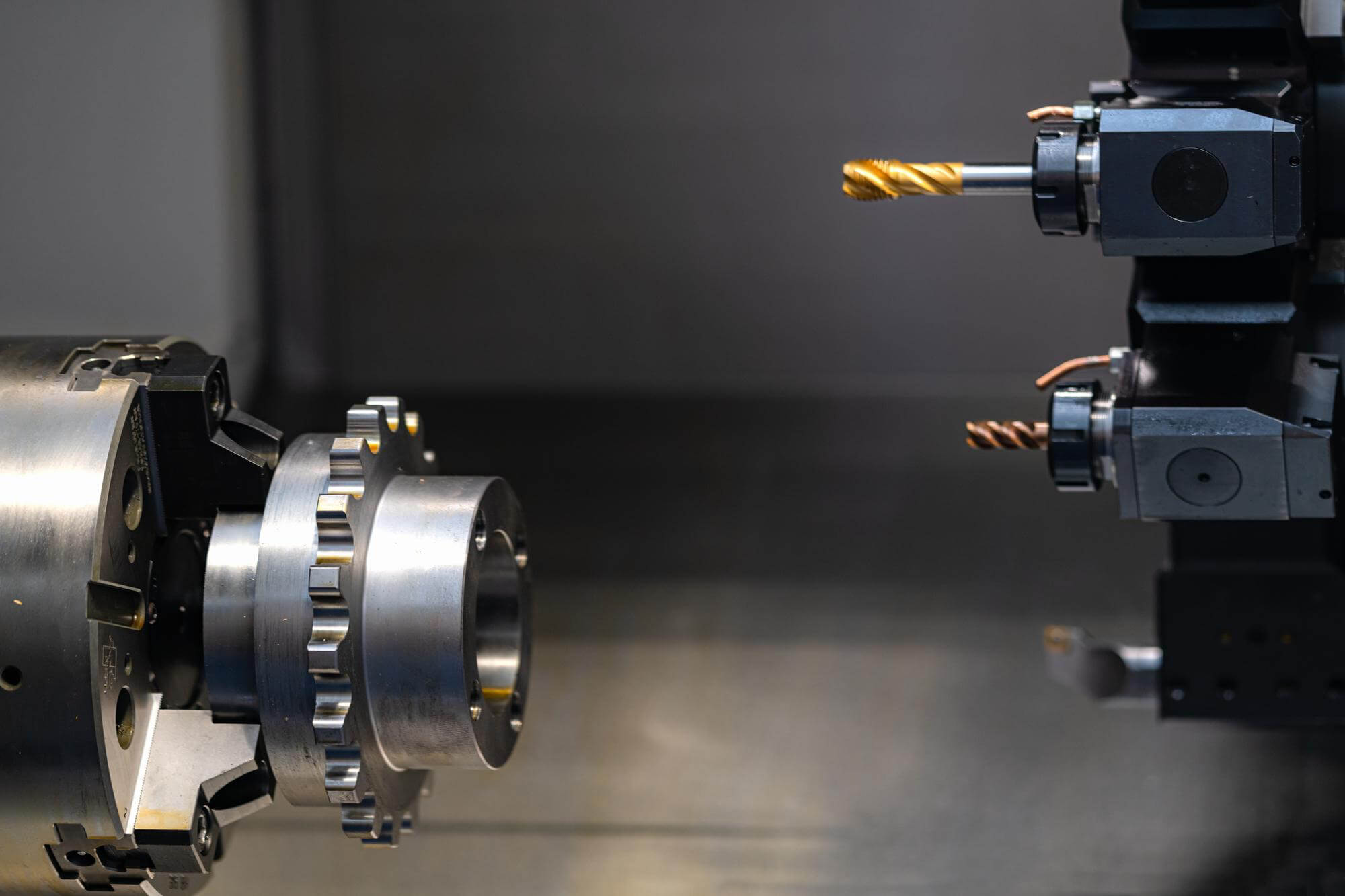

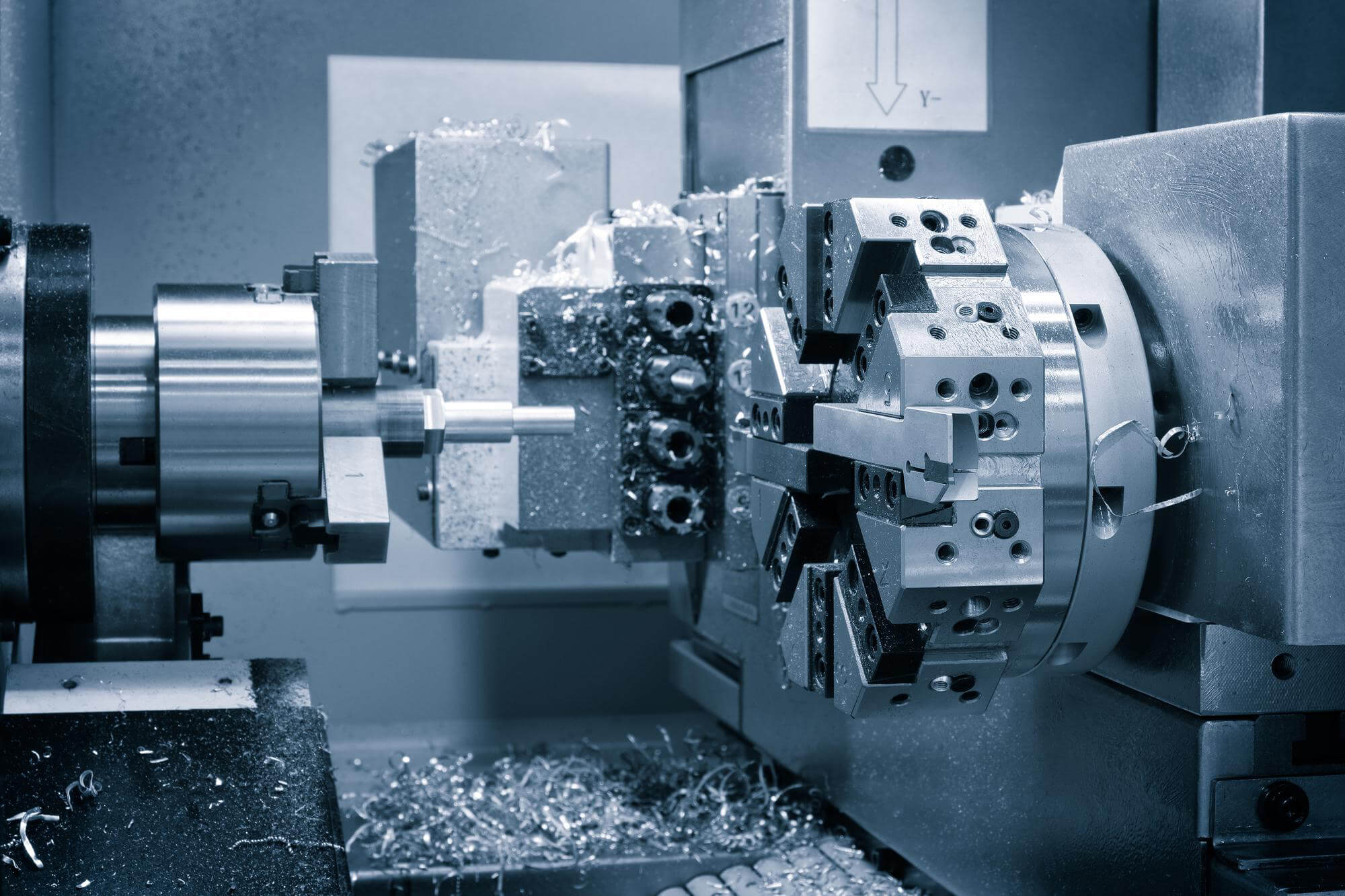

CNC machining, particularly on lathes, can be a complex process, but understanding and utilizing constant surface speed (CSS) techniques can

CNC machining can seem like a complex dance of metal and math, but getting the spindle speed right is one

CNC machining is a blend of art and science, and mastering spindle rotation control can significantly enhance the quality and

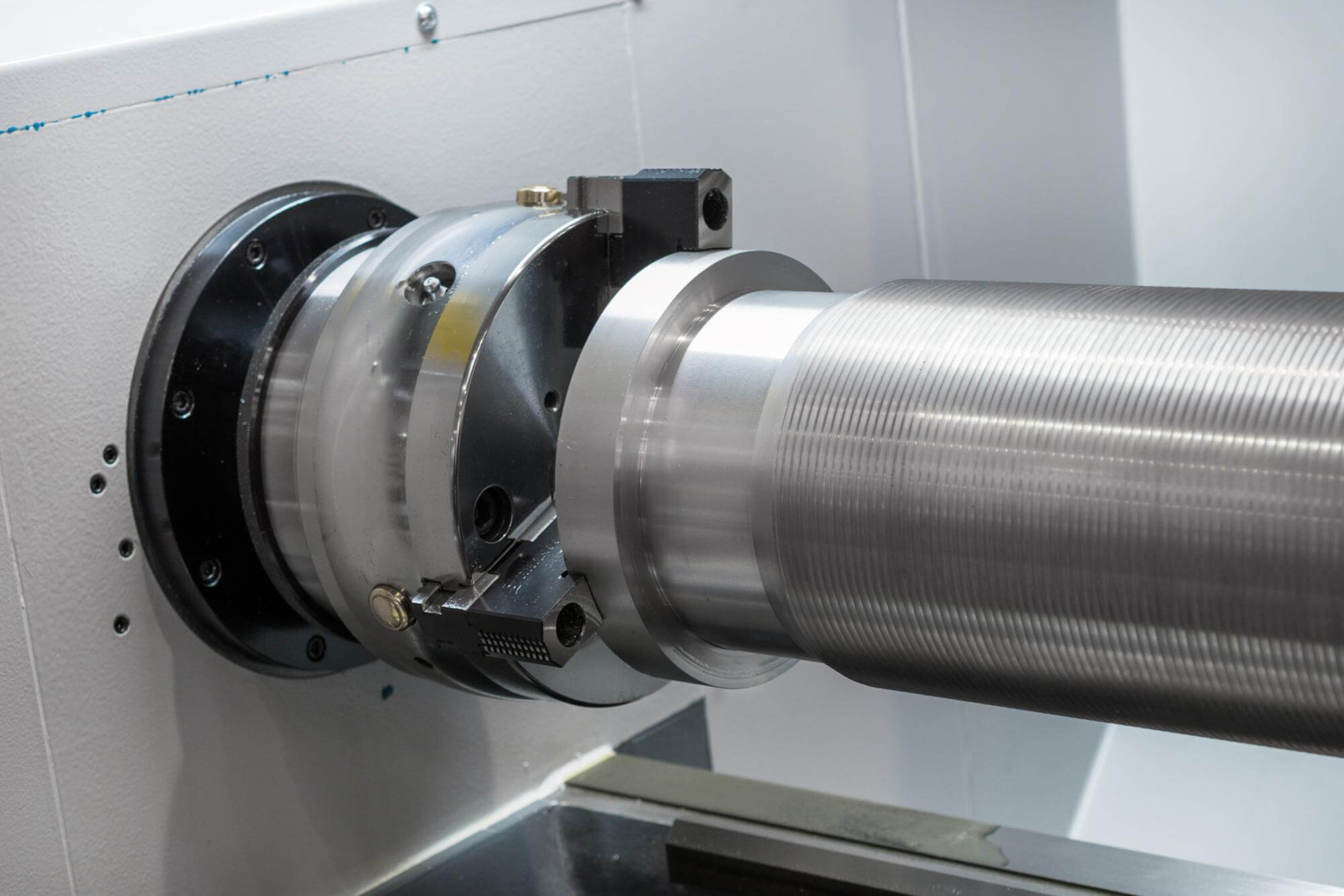

CNC machining is a fascinating world where precision meets creativity. At the heart of this intricate dance is the spindle,

Insert Shapes and Naming Standards International Insert Naming Standards The naming of CNC turning inserts follows international standards, which mainly

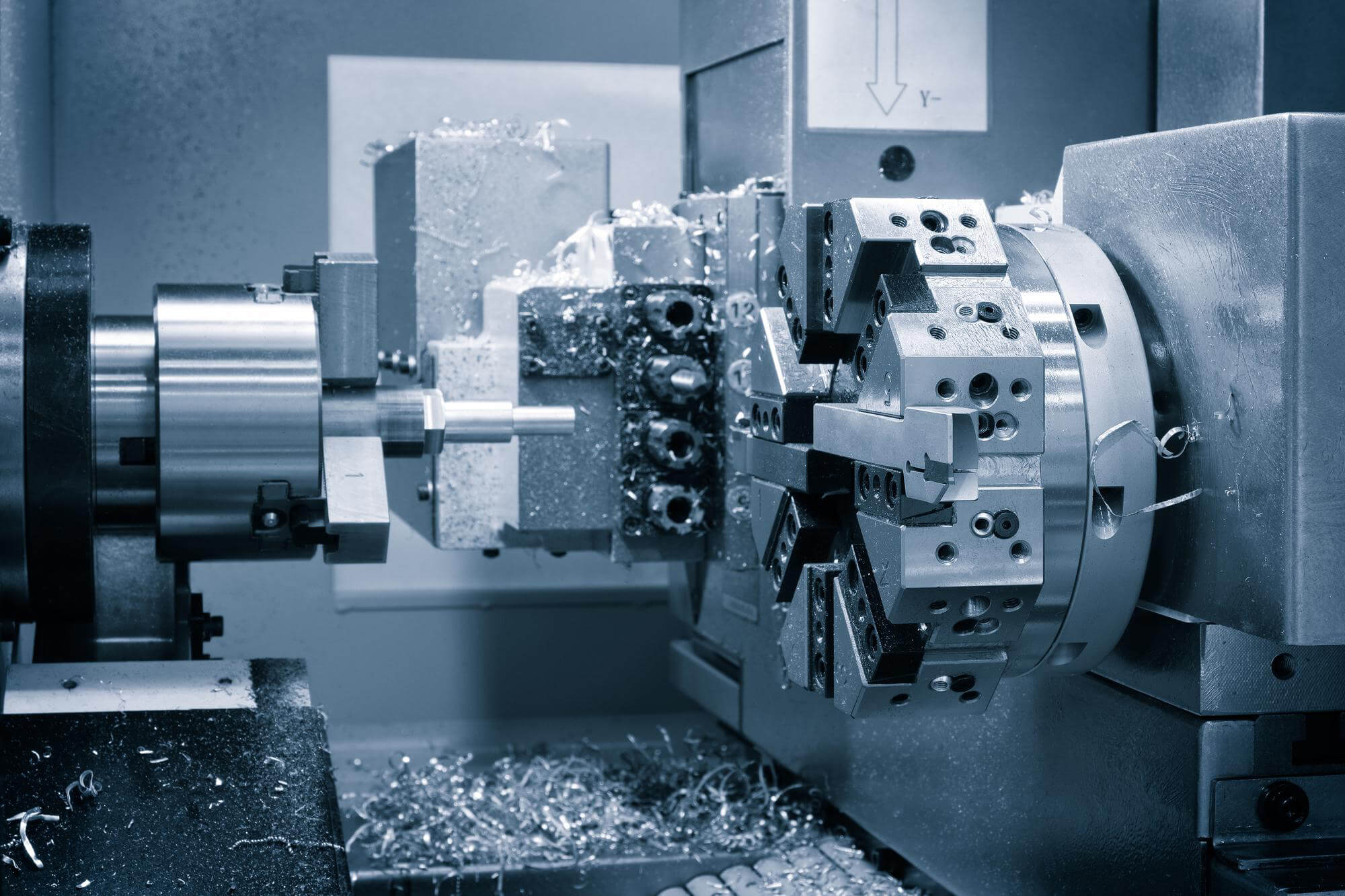

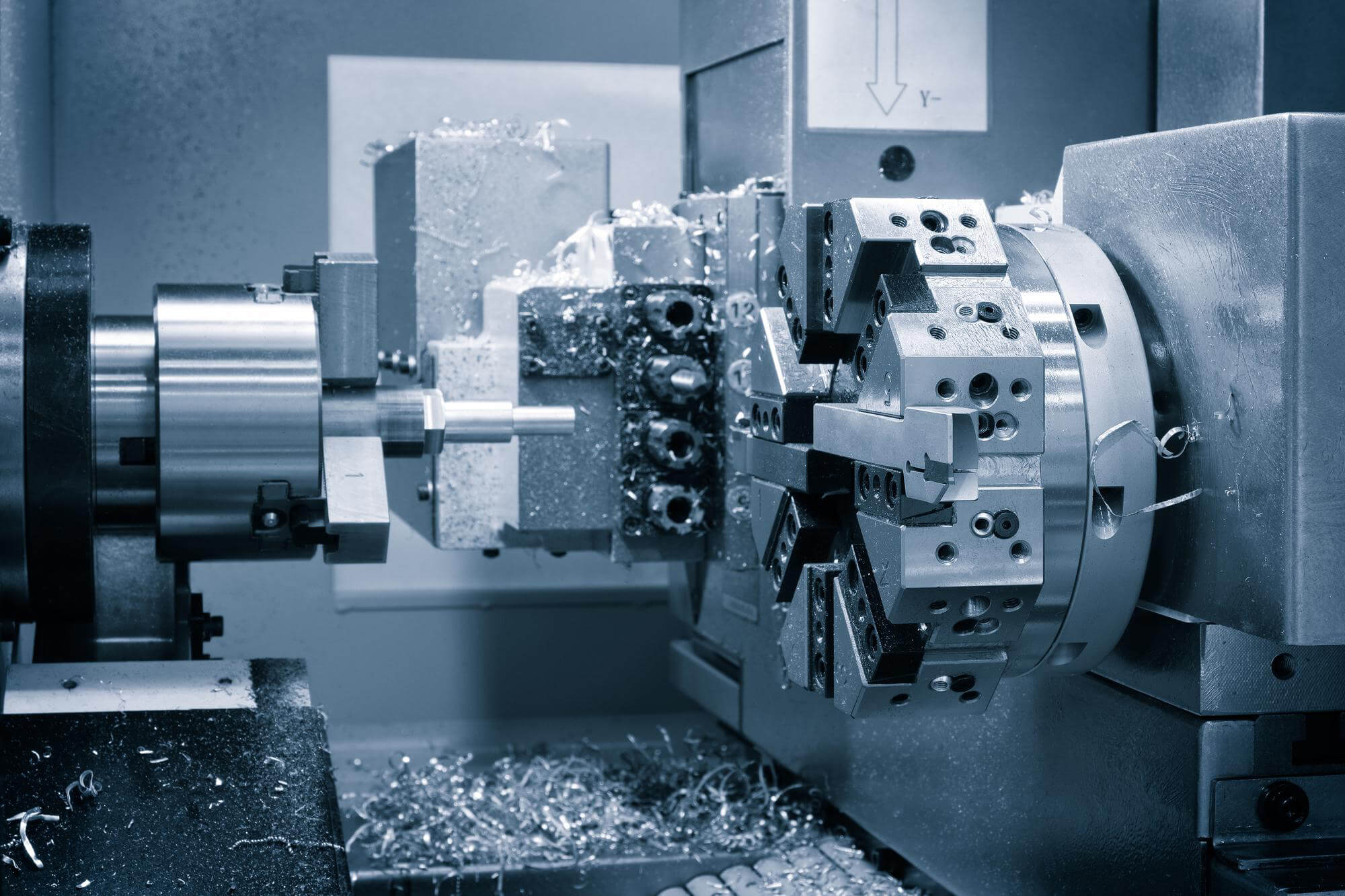

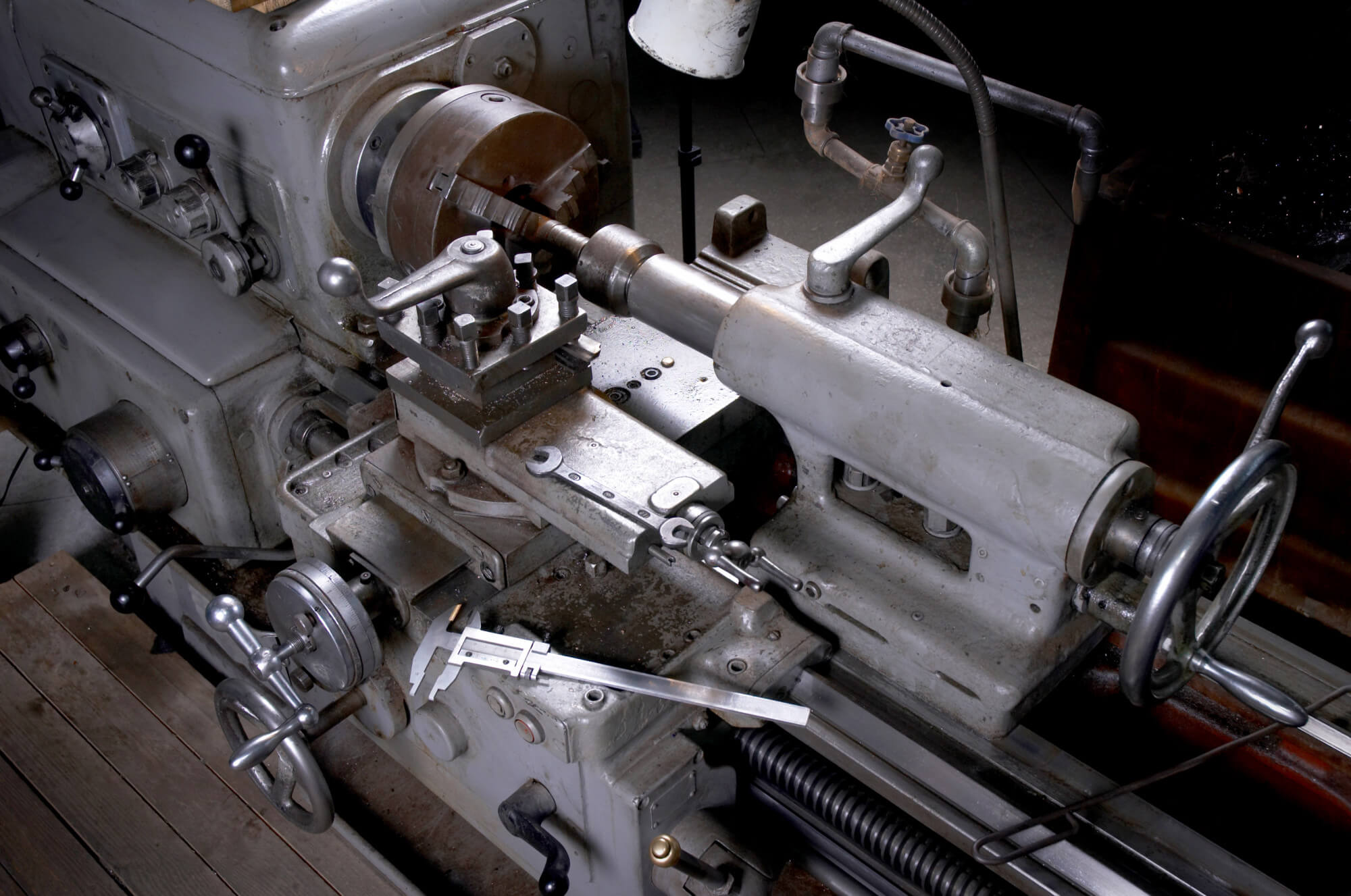

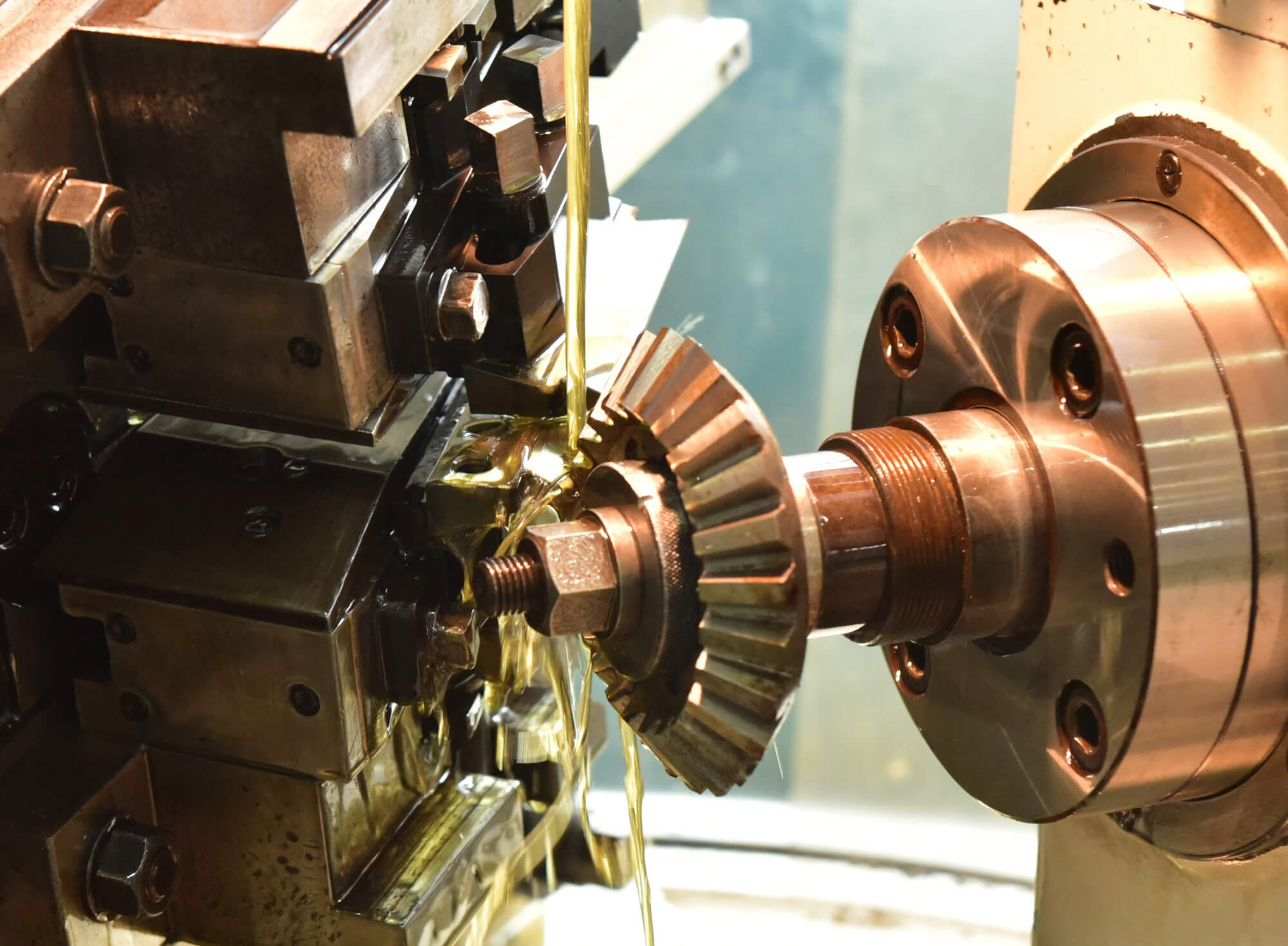

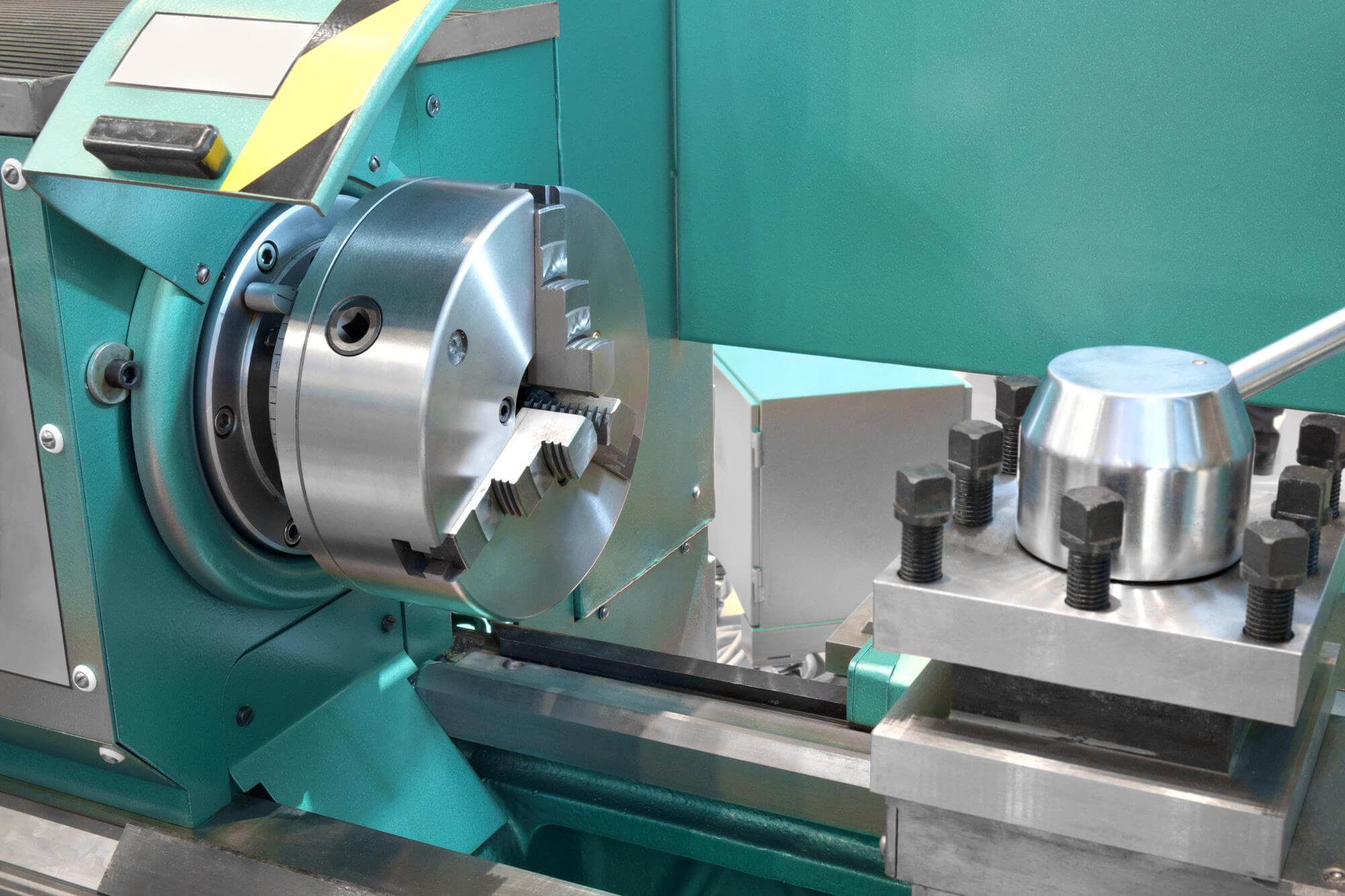

Overview of Metal Cutting Machine Tools Metal cutting machine tools are machines that use tools or abrasives to cut metal

Principles of Blank Selection In mechanical manufacturing, the selection of blanks is crucial as it not only affects product quality

In machining, controlling precision is a crucial aspect that directly affects the quality and performance of the final product. This

Machining precision refers to the degree to which the actual geometric parameters of a machined part conform to the ideal

You’re one step from the factory-direct price of part manufacturing services.