Understanding the Different Types of Plastic for CNC Machining

Title: Understanding the Different Types of Plastic for CNC Machining Introduction CNC machining, a revered and precise manufacturing process, is not limited to metals and alloys. Plastics, with their versatile properties, have become a staple in CNC machining, offering unique advantages in various applications. This article delves into the world of plastics in CNC machining, […]

Galvanized Steel vs Aluminum: Understanding the Key Differences

Introduction In the realm of metalworking and manufacturing, two materials often dominate the conversation: Galvanized Steel and Aluminum. Both are extensively used across various industries, from construction to automotive manufacturing, due to their unique properties and benefits. This article delves into the fundamental differences between these two metals, exploring aspects like composition, durability, applications, and […]

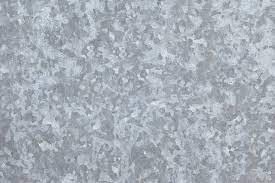

Title: Galvanized Steel: Process, Methods, Properties, and Uses

Introduction: Galvanized steel, an innovation in the world of construction and manufacturing, represents a pinnacle in material engineering. It’s a process where steel is coated with a protective layer of zinc, enhancing its durability and resistance to environmental factors. This article delves deep into the galvanization process, exploring its methods, properties, and the diverse applications […]

Hot-Dip Galvanizing: Purpose, Process, and Uses

Introduction to Hot-Dip Galvanizing Hot-dip galvanizing, a process widely recognized in the industrial world, plays a crucial role in enhancing the durability and longevity of steel and iron products. This process involves coating metal items with a thin layer of zinc, offering them robust protection against rust and corrosion. This article delves into the details […]

Galvanized vs. Galvanneal: What Are the Differences?

In the realm of metal finishing and corrosion protection, two processes often come up: galvanizing and galvannealing. Both methods enhance the durability and longevity of steel and other metal products, but they serve different purposes and exhibit distinct characteristics. This article delves into the nuances of these two processes, highlighting their differences, applications, and advantages. […]

Types of Stainless Steel and Stainless Steel Grades

Stainless steel, renowned for its corrosion resistance, is a vital material in various industries, from construction to culinary tools. This article delves into the types of stainless steel and their grades, offering a comprehensive understanding of their unique properties and applications. What is Stainless Steel? Stainless steel is an iron alloy with a minimum of […]