In the realm of metal finishing and corrosion protection, two processes often come up: galvanizing and galvannealing. Both methods enhance the durability and longevity of steel and other metal products, but they serve different purposes and exhibit distinct characteristics. This article delves into the nuances of these two processes, highlighting their differences, applications, and advantages.

What is Galvanized Steel?

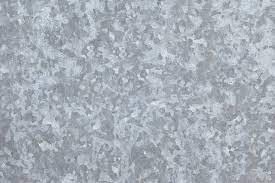

Galvanizing is a process of applying a protective zinc coating to steel or iron, to prevent rusting. The most common method is hot-dip galvanizing, where the steel is submerged in a bath of molten zinc.

Process of Galvanizing

- Surface Preparation: The steel is cleaned to remove any impurities, often through a degreasing process.

- Dipping: The prepared steel is dipped into a bath of molten zinc at around 450°C.

- Cooling: After being removed from the bath, the steel cools down, forming a layer of zinc tightly bonded to the surface.

Advantages of Galvanizing

- Long-lasting Protection: The zinc coating provides excellent protection against corrosion.

- Economical: It is cost-effective over the long term, due to its durability.

- Maintenance-Free: Once galvanized, the steel requires little to no maintenance.

Applications of Galvanized Steel Galvanized steel is widely used in outdoor applications where weather resistance is crucial, such as in fencing, railings, and automotive body parts.

What is Galvanneal Steel?

Galvanneal, a portmanteau of galvanize and anneal, refers to steel that has gone through the galvanization process and then been annealed. This process involves heating the galvanized steel in an air-free environment, which causes the zinc and steel to interdiffuse.

Process of Galvannealing

- Galvanizing: The steel is first galvanized by the usual hot-dip method.

- Annealing: The galvanized steel is then heated in an annealing furnace, where it forms a zinc-iron alloy layer.

- Cooling: The steel cools at room temperature, solidifying the alloy coating.

Advantages of Galvanneal

- Enhanced Paintability: The surface is excellent for painting, as the alloy coating is rougher and more porous.

- Better Weldability: It offers better weldability compared to standard galvanized steel.

- Corrosion Resistance: While it’s slightly less resistant to corrosion than galvanized steel, it still provides substantial protection.

Applications of Galvanneal Steel Galvanneal is often used in applications where paintability is important, like in automotive panels, architectural designs, and manufacturing of metal cabinets.

Key Differences Between Galvanized and Galvanneal Steel

- Coating Composition: Galvanized steel has a pure zinc coating, while galvanneal steel has a zinc-iron alloy coating.

- Surface Texture: Galvanized steel has a smoother surface, while galvanneal provides a rougher surface ideal for painting.

- Corrosion Resistance: Galvanized steel typically offers superior corrosion resistance.

- Weldability: Galvanneal steel is easier to weld.

- Application Areas: Galvanized steel is preferred for outdoor uses, while galvanneal is suited for applications requiring painting and welding.

FAQs

Is galvanneal steel as durable as galvanized steel? Galvanneal steel offers slightly less corrosion resistance but is more durable when painted, due to better adhesion.

Can galvanized steel be painted? Yes, but the surface needs special treatment like etching for proper paint adhesion, unlike galvanneal steel.

Conclusion Choosing between galvanized and galvanneal steel depends on the specific requirements of your project. For environments demanding robust corrosion resistance, galvanized steel is ideal. Conversely, for projects where paintability and weldability are priorities, galvanneal steel is the better option. Understanding these differences ensures that the right type of steel is employed for the right application, leading to more effective and durable outcomes.

Interested in Customized Metal Finishing Services? For professional guidance and services in metal finishing, reach out to [Your Company Name]. Our expertise in galvanized and galvanneal steel will ensure your project meets its specific needs with the highest quality standards. Contact us today to get started!

Related Posts

- Alloy steel vs stainless steel

Introduction to Alloy Steel and Stainless Steel An alloy is a combination of metals or a metal mixed with one or more elements, engineered to enhance material properties such as…

- Galvanized Steel vs Aluminum: Understanding the Key Differences

Introduction In the realm of metalworking and manufacturing, two materials often dominate the conversation: Galvanized Steel and Aluminum. Both are extensively used across various industries, from construction to automotive manufacturing,…

- Title: Galvanized Steel: Process, Methods, Properties, and Uses

Introduction: Galvanized steel, an innovation in the world of construction and manufacturing, represents a pinnacle in material engineering. It's a process where steel is coated with a protective layer of…