The Art of Burnished Bronze: Exploring Machining and Polishing Methods

Introduction Burnished bronze has been a material of fascination for many over the centuries. Whether you’re an artist crafting a masterpiece or an engineer designing industrial components, burnished bronze offers a remarkable combination of beauty, strength, and functionality. As someone who has spent years experimenting with different alloys and finishes, I can personally attest to […]

Brass Tacks Demystified: A Deep Dive into Machining Techniques and Innovations

I’ve spent a fair bit of time learning about different metal fasteners, and brass tacks are one of those intriguing items that bridge function and design. When you look at a finished piece of furniture or a detailed decorative panel, you might notice small round-headed tacks that seem to enhance the overall look. Those are […]

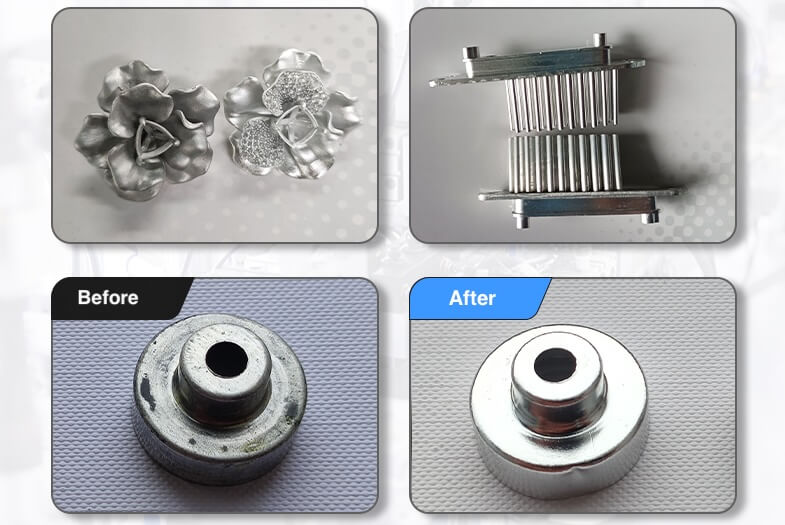

The Complete Guide to Polishing Aluminum: Challenges and Solutions for Machinists

Introduction – Polishing Aluminum and Why It Matters I remember the first time I tried polishing aluminum. I wanted a clean, glossy finish but ended up with swirl marks and uneven patches. Later, I realized that polishing aluminum can be simpler once you understand the right techniques, tools, and alloy traits. My goal here is […]

Brushed Aluminum Demystified: From Elegance to Engineering

I’ve spent a fair amount of time working with different metals, and Brushed Aluminum has always caught my eye. It’s a material that combines an appealing, decorative surface with properties that are seriously valued in engineering. Whether you’re a designer looking for the perfect finish or an engineer aiming for a specific performance, brushed aluminum […]

Polyamide vs Polyester: Cost, Durability & CNC Machining Tips

When it comes to CNC machining custom parts, material selection is one of the most critical decisions. Two of the most popular engineering plastics—polyamide (commonly known as nylon) and polyester (often represented as PET)—offer a range of benefits but have different properties that make them suitable for specific applications. Understanding the differences between these materials […]

Comparing Tungsten vs Titanium for Custom Parts with CNC Technology

Introduction In high-performance industries such as aerospace, medical devices, automotive, and defense, selecting the right material is crucial to meeting specific application needs. Two materials that often stand out due to their unique properties are tungsten and titanium. Both materials offer advantages, but their distinct differences make them better suited for certain projects. This article […]

Composite Material Forming Techniques: Process, Advantages, and Innovative Applications

Introduction to Composite Material Forming Techniques Composite materials are engineered from two or more constituents with distinct physical and chemical properties, which remain separate and distinct within the finished structure. The significance of advanced forming techniques for composites cannot be overstated; they enable the manufacturing of complex shapes that often cannot be achieved through traditional […]

Understanding the Different Types of Plastic for CNC Machining

Title: Understanding the Different Types of Plastic for CNC Machining Introduction CNC machining, a revered and precise manufacturing process, is not limited to metals and alloys. Plastics, with their versatile properties, have become a staple in CNC machining, offering unique advantages in various applications. This article delves into the world of plastics in CNC machining, […]

Galvanized Steel vs Aluminum: Understanding the Key Differences

Introduction In the realm of metalworking and manufacturing, two materials often dominate the conversation: Galvanized Steel and Aluminum. Both are extensively used across various industries, from construction to automotive manufacturing, due to their unique properties and benefits. This article delves into the fundamental differences between these two metals, exploring aspects like composition, durability, applications, and […]

Title: Galvanized Steel: Process, Methods, Properties, and Uses

Introduction: Galvanized steel, an innovation in the world of construction and manufacturing, represents a pinnacle in material engineering. It’s a process where steel is coated with a protective layer of zinc, enhancing its durability and resistance to environmental factors. This article delves deep into the galvanization process, exploring its methods, properties, and the diverse applications […]

Hot-Dip Galvanizing: Purpose, Process, and Uses

Introduction to Hot-Dip Galvanizing Hot-dip galvanizing, a process widely recognized in the industrial world, plays a crucial role in enhancing the durability and longevity of steel and iron products. This process involves coating metal items with a thin layer of zinc, offering them robust protection against rust and corrosion. This article delves into the details […]

Galvanized vs. Galvanneal: What Are the Differences?

In the realm of metal finishing and corrosion protection, two processes often come up: galvanizing and galvannealing. Both methods enhance the durability and longevity of steel and other metal products, but they serve different purposes and exhibit distinct characteristics. This article delves into the nuances of these two processes, highlighting their differences, applications, and advantages. […]