The Evolution of Gear Shaft Machining: A Historical Perspective

The inception of gear shaft manufacturing dates back to the industrial revolution, but the most transformative era for this craft began with the advent of Computer Numerical Control (CNC) technology. Initially, gear shafts were created through manual processes that required the meticulous labor of skilled craftsmen. These early methods were time-consuming and often lacked precision. With the integration of CNC, the production of gear shafts became more accurate and vastly more efficient.

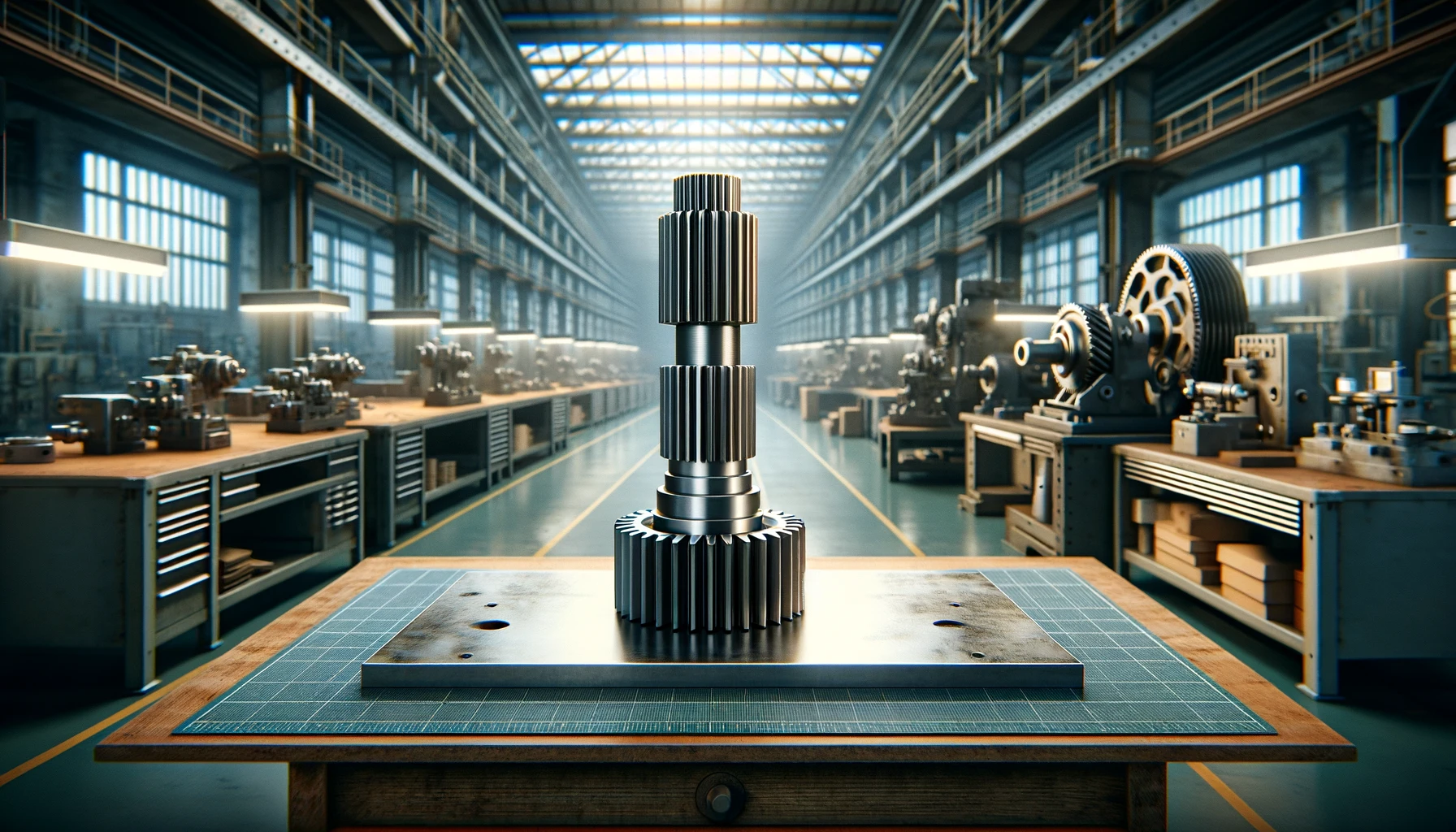

Introduction: The Revolution of Gear Shafts in China’s CNC Industry

China’s emergence as a powerhouse in CNC machining for gear shafts is a story of innovation, investment, and strategy. The country’s manufacturing sector has undergone a significant transformation, driven by technological advancements and a strong push towards industrial modernization. This revolution has positioned China as a leading player in the precision engineering arena, particularly in the crafting of gear shafts for a multitude of industries.Now, in order to better serve customers, suppliers also provide online CNC machining services.

Material Selection: The Foundation of Superior Gear Shafts

The foundation of superior gear shafts lies in the meticulous selection of materials. Each material brings its own set of properties that can dramatically affect the performance and longevity of the gear shaft. Traditionally, materials such as carbon steel and bronze were commonplace, but advancements in material science have introduced a variety of superior alloys and metals, each tailored for specific applications.

SAE 4340 alloy steel, for example, has emerged as a frontrunner in the industry due to its remarkable tensile strength and robustness, which are crucial in the high-stress environments gear shafts often operate in. Its composition includes chromium, molybdenum, and nickel, which collectively contribute to its ability to resist wear and fatigue.

Consider the case of a gear shaft used in a high-performance automotive transmission. The material must withstand high torque and rapid shifts in rotational speed. A switch from a traditional carbon steel to SAE 4340 alloy steel can result in a gear shaft that not only handles the increased stress but also lasts longer before showing signs of wear. This transition exemplifies the critical role material selection plays in enhancing the performance and reliability of CNC machined components.

Innovative Techniques in CNC Machining of Gear Shafts

As the demand for more complex and precise gear shafts grows, so too does the need for innovative CNC machining techniques. The advent of 5-axis CNC machines has revolutionized the manufacturing process, allowing for the production of gear shafts with intricate designs and features that were once deemed impossible.

This innovation has opened up new possibilities in terms of the complexity of gear shafts that can be produced. For instance, 5-axis machines facilitate the creation of helical gear shafts with exceptional precision, which are essential in applications such as aerospace and high-performance automotive industries. The helical design requires complex machining, which 5-axis technology handles with ease, producing components with extremely tight tolerances.

In one particular case, a leading aerospace components manufacturer leveraged 5-axis machining to produce gear shafts that could withstand the extreme conditions of aerospace applications. The precision of the 5-axis process allowed for the creation of gear shafts that met the rigorous standards of the industry, contributing to the overall safety and performance of aerospace machinery.

Quality Control: Ensuring Excellence in Gear Shaft Production

Quality control stands as a pivotal process in the production of gear shafts, where the margin for error is virtually nonexistent. Precision is paramount, and even the slightest deviation can lead to a component’s failure. To mitigate this, manufacturers employ a variety of advanced metrology tools, with coordinate measuring machines (CMMs) being among the most critical.

CMMs offer unparalleled accuracy in measuring the physical geometrical characteristics of a part. By using these devices, manufacturers can ensure that each gear shaft is produced within the defined tolerances. For example, a notable automotive gear shaft manufacturer introduced a CMM into their production line, which allowed them to detect and correct micron-level inaccuracies in real-time, effectively reducing their waste and improving their output quality.

In addition to employing CMMs, quality control also encompasses a comprehensive inspection regime that includes material testing, process monitoring, and final inspection. By adhering to stringent quality standards, manufacturers are able to deliver gear shafts that are not only precise but also reliable and durable, thereby satisfying the high expectations of their clients and maintaining a competitive edge in the market.

Precision Engineering: The Heart of China’s CNC Craft

Precision engineering is at the core of CNC machining, particularly in the production of intricate components like gear shafts. Achieving ultra-fine tolerances is essential in sectors such as aerospace and automotive, where the smallest imperfection can lead to catastrophic failures. Chinese manufacturers have excelled in this area, employing state-of-the-art CNC equipment and skilled technicians to produce gear shafts with tolerances as tight as +/- 0.0002 inches. This level of precision ensures the seamless integration of shafts into complex assemblies, highlighting the advanced capabilities of China’s CNC machining industry.

Case Studies: Successful Applications of China’s CNC Gear Shafts

The application of China’s CNC-machined gear shafts spans various industries, demonstrating their versatility and reliability. In the automotive sector, a leading car manufacturer adopted Chinese CNC gear shafts for its transmission systems, resulting in enhanced vehicle performance and reduced maintenance needs. Another example is in the field of renewable energy, where wind turbine manufacturers have utilized these precision shafts to improve the efficiency and longevity of their installations. These case studies exemplify the global reach and impact of China’s CNC machining prowess.

Other Articles You Might Enjoy

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- CNC Precision in Crafting Bearing Shafts

Bearing shafts play a critical role in various mechanical systems, providing support and enabling smooth rotational movement. The precision required in crafting these components is paramount to ensure optimal performance…