Introduction to Chrome in CNC Applications

Chrome, known for its gleaming finish and remarkable durability, plays a pivotal role in CNC (Computer Numerical Control) machining. Its application spans various industries, prominently automotive and aerospace, where the longevity and aesthetic appeal of components are paramount. The process of incorporating chrome into CNC operations, primarily through electroplating, enhances the wear resistance and reduces the corrosion susceptibility of metal parts.

Environmental Impact of Chrome in Manufacturing

The environmental impact of chromium use in manufacturing, especially in chrome plating for CNC machining, is significant. The main concern is the release of hexavalent chromium (Cr(VI)), a toxic and carcinogenic form, into the environment. This occurs through wastewater from manufacturing sites, contaminating local water bodies and potentially affecting drinking water sources. Hexavalent chromium in water can harm aquatic life and disrupt ecosystems.

Soil contamination near industrial areas can degrade soil quality and harm terrestrial ecosystems by affecting plant life. Additionally, airborne chromium particles from manufacturing processes can degrade air quality, posing health risks to workers and nearby residents, primarily through respiratory issues.

Addressing these environmental challenges requires implementing advanced wastewater treatment technologies, strict emission controls, and adopting sustainable practices like closed-loop systems to reduce waste. Effective regulatory measures are essential to enforce environmental standards and minimize chromium’s harmful impacts.

Health Concerns Associated with Chrome Exposure

Exposure to hexavalent chromium (Cr(VI)), a toxic and carcinogenic substance used in chrome plating and other industrial processes, raises substantial health concerns. In occupational settings, workers face risks from inhaling airborne Cr(VI) particles and direct skin contact. Inhalation can lead to severe respiratory issues, including lung cancer, nasal damage, and asthma-like symptoms, given Cr(VI)’s classification as a Group 1 carcinogen by the International Agency for Research on Cancer (IARC).

Skin exposure to Cr(VI) often results in dermatitis and persistent skin ulcers, particularly on the hands and forearms. Long-term exposure can also affect the eyes, liver, kidneys, and immune system, though respiratory problems are the most prominent health risk associated with Cr(VI).

The wider population might encounter Cr(VI) through contaminated drinking water, air, and soil, a concern highlighted by high-profile cases like the water contamination in Hinkley, California. Such environmental exposure links to increased cancer rates and chronic health conditions, emphasizing the need for rigorous pollution control and public health protections.

Technical Challenges in Effective Chrome Removal

Removing chrome from CNC machinery involves navigating a complex landscape of technical hurdles, each presenting unique challenges to manufacturers.

Adherence and Material Integrity: Chrome’s tenacious adherence to metal surfaces necessitates precision in removal techniques to maintain the integrity of the underlying material. This balance is challenging to strike, often requiring high-precision methods like laser ablation, which, while effective, can be prohibitively expensive for small-scale operations.

Toxic By-products: The chemical stripping process, a common method for removing chrome, can generate hazardous waste, necessitating careful handling, treatment, and disposal to minimize environmental impact.

Regulatory Compliance: Adhering to strict environmental regulations adds another layer of complexity, requiring manufacturers to constantly evolve their chrome removal processes to comply with the latest standards.

Data Table: Comparison of Chrome Removal Methods

| Method | Efficacy | Cost | Environmental Impact | Compliance | Energy Use | Waste Produced | Setup Time | Maintenance Needs | Safety |

|---|---|---|---|---|---|---|---|---|---|

| Chemical Stripping | High | Low | High | Moderate | Low | High | Low | High | Moderate |

| Laser Ablation | Very High | High | Low | High | High | Low | High | Moderate | High |

| Electrolysis | Moderate | Moderate | Moderate | High | Moderate | Moderate | Moderate | Moderate | Moderate |

| Mechanical Peeling | Low | Very Low | High | Low | Very Low | Very High | Very Low | Low | Low |

Cost and Efficiency Considerations in Chrome Detoxification

The economic implications of chrome removal are multifaceted, including both the direct costs of removal and the broader indirect costs associated with environmental, health, and regulatory factors.

Direct Costs: These encompass equipment acquisition, maintenance, consumables, and energy consumption associated with the removal process.

Indirect Costs: Longer-term costs include potential environmental cleanup, health care for affected workers, and compliance with stringent environmental regulations, which can vary significantly by region and over time.

Cost-Benefit Analysis: Investing in more efficient, albeit initially more costly, chrome removal technologies can lead to substantial long-term savings. These savings stem from reduced environmental and health-related costs, as well as from avoiding potential fines for regulatory non-compliance.

Data Table: Cost-Benefit Analysis of Chrome Removal Technologies

| Technology | Initial Investment | Operational Cost per Year | Environmental Savings per Year | Health-Related Savings per Year | Regulatory Compliance Savings per Year |

|---|---|---|---|---|---|

| Chemical Stripping | $50,000 | $5,000 | $2,000 | $3,000 | $1,000 |

| Laser Ablation | $150,000 | $10,000 | $10,000 | $5,000 | $5,000 |

| Electrolysis | $100,000 | $7,500 | $4,000 | $4,000 | $3,000 |

| Mechanical Peeling | $10,000 | $1,000 | $500 | $1,000 | $500 |

Innovative Technologies for Chrome Removal in China

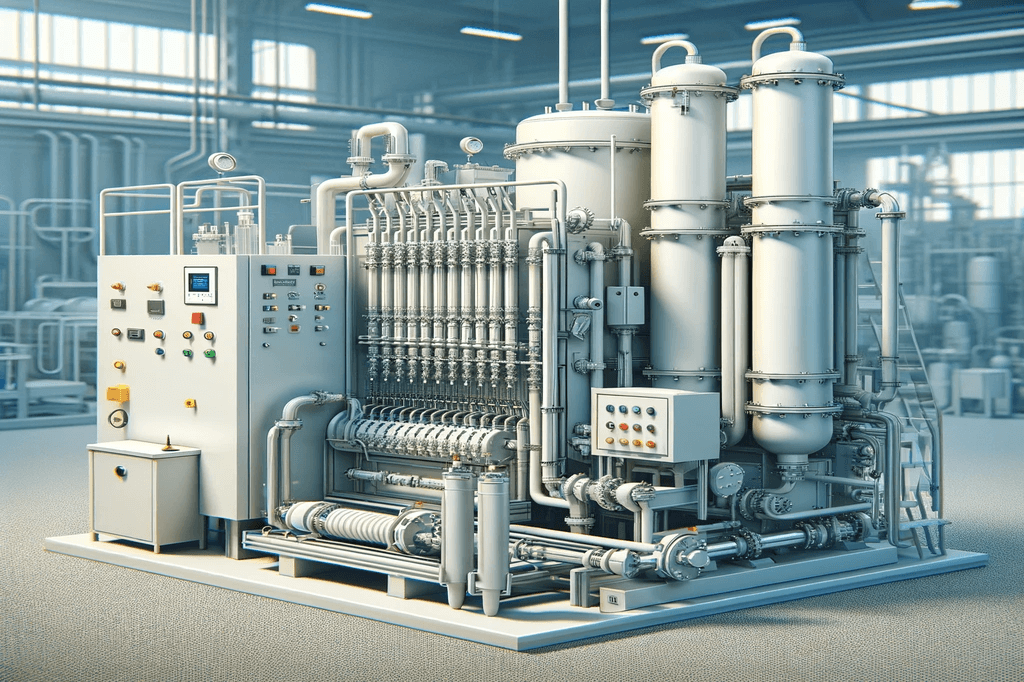

In response to the environmental and health impacts of chromium, China is pioneering innovative chrome removal technologies. Electrochemical treatment stands out, utilizing electrodes to convert harmful hexavalent chromium (Cr(VI)) into less toxic trivalent chromium (Cr(III)), with nanotechnology enhancing the process’s efficiency. Bioremediation offers an eco-friendly alternative, employing microorganisms and plants to absorb and transform Cr(VI), leveraging nature’s own mechanisms for detoxification.

Advances in membrane technology, featuring materials like graphene oxide, provide scalable solutions for removing chromium from wastewater, suitable for widespread industrial application. Additionally, China’s commitment to a circular economy is driving the development of chromium recovery and recycling systems, reducing waste and reintegrating chromium into the manufacturing cycle.

These innovations, supported by China’s proactive environmental policies, mark a significant stride toward sustainable industrial practices, minimizing the ecological footprint of chromium use and setting a benchmark for global manufacturing standards

Other Articles You Might Enjoy

- Pioneering Chrome Removal in CNC

Pioneering Chrome Removal in CNC Computer Numerical Control (CNC) machines are pivotal to the manufacturing industry, offering pristine accuracy and repeatability in a wide range of tasks - from simple…

- China's Approach to Flawless CNC Chrome Removal

Introduction In the realm of CNC machining, the process of chrome removal is critical for achieving the desired quality and finish in manufactured products. As a global manufacturing powerhouse, China…

- Titanium Grade 5 vs. Grade 23 in CNC Machining: Which is More Efficient?

Introduction: Titanium Grade 5 vs. Grade 23 in CNC Machining In the realm of Computer Numerical Control (CNC) machining, the use of titanium-based materials is quite prevalent due to their…