Introduction

When I first got into CNC machining, I didn’t pay much attention to material types. I just followed blueprints, mounted the blocks, and let the machine do its thing. But over time, I realized that what really determines the quality—and cost—of a part isn’t just the design or the toolpath. It’s the material. And if there’s one material that keeps coming back in projects from automotive to electronics, it’s cold rolled steel.

Cold rolled steel (CRS) sounds simple—just steel that’s rolled at room temperature, right? But in practice, it’s a category packed with nuances. From mechanical strength to surface finish, it behaves differently under a CNC cutter than many other metals I’ve worked with.

In this guide, I want to break down everything I’ve learned about machining cold rolled steel. I’ll walk through the material types, explain how it responds to different CNC methods, and share cutting strategies that have worked for me—and what mistakes to avoid. Whether you’re an engineer, machinist, or just curious about why CRS is so widely used, I hope this guide gives you both clarity and practical takeaways.

I’ve structured the content in a way that covers the full CNC workflow—from choosing the right steel to optimizing cut speeds and dealing with burrs. And since this article is also for people looking through Google, I’ve made sure to surface everything that someone searching for cold rolled steel would want to know.

Understanding Cold Rolled Steel Materials

Cold rolled steel isn’t just one thing. It’s a whole family of low-carbon and mild steels that are processed below their recrystallization temperature. What makes it different from hot rolled steel is the way it’s finished—more precise, smoother, tighter in tolerance. If you’ve ever held a clean, uniform steel sheet with a shiny grayish finish, chances are you’ve handled cold rolled steel.

I remember one of my first shop jobs where we received two shipments—one was hot rolled and covered in mill scale, and the other was cold rolled, smooth as glass. That’s when it really clicked for me how different they were to work with, especially when running parts that required post-finishing.

Key Features of Cold Rolled Steel

Here are the main characteristics I look for when deciding if CRS is the right fit:

- Higher dimensional precision – ideal for CNC work where tolerances matter.

- Smooth surface finish – reduces prep time before coating or welding.

- Stronger and harder than hot rolled steel – due to strain hardening during processing.

- Consistent grain structure – leads to predictable machining behavior.

Common Cold Rolled Steel Grades

Let’s break down the grades I’ve worked with most often in CNC projects:

| Grade | Typical Use | Strength (MPa) | Yield Strength (MPa) | Machinability (%) | Notes |

|---|---|---|---|---|---|

| SPCC | General-purpose parts | ~270 | ~140 | 45–50 | Low carbon, good for forming |

| Q195 | Structural, light-duty | ~335 | ~195 | 50–55 | Very ductile, inexpensive |

| Q235 | Machinery components | ~370 | ~235 | 50–60 | Balanced strength and workability |

| SAE 1008 | Auto body panels | ~280 | ~170 | 55–60 | Excellent surface finish |

| SAE 1010 | Fasteners, clamps | ~340 | ~180 | 60–65 | Slightly higher carbon |

| A366/1008 | Deep draw parts | ~290 | ~160 | 55 | Ideal for fine forming |

Most of these grades fall into the mild steel category, with carbon content below 0.25%. The low carbon content gives you great weldability and decent machinability—but don’t expect performance like hardened tool steel. That’s not what cold rolled steel is for.

How Cold Rolled Steel is Made

The process starts with hot rolled steel, which is then cooled and re-rolled at room temperature. This extra step gives CRS its tighter tolerances and better surface finish. But it also work-hardens the metal, making it stronger and less ductile in its final form.

That hardness is a double-edged sword when it comes to CNC machining. On one hand, the improved stability is great for holding tight dimensions. On the other, it can wear down your tools faster if you’re not careful.

Why Use Cold Rolled Steel in CNC Projects?

I’ve found CRS ideal for the following situations:

- When parts need to be coated or painted—thanks to its clean surface

- When I need to minimize warping or distortion in thin-walled designs

- When the client wants a cost-effective steel that still looks good

It’s especially useful for enclosures, brackets, and housings—things where precision and appearance both matter.

Machinability of Cold Rolled Steel in CNC Applications

When I first started cutting cold rolled steel, I expected it to behave just like mild hot rolled steel. It didn’t. The tools wore down faster, the edges didn’t always come out clean, and sometimes I’d get unexpected chatter—even with standard feeds and speeds. That’s when I realized: cold rolled steel has its own quirks when it comes to CNC machining.

What Affects the Machinability of Cold Rolled Steel

There are a few key things that influence how cold rolled steel performs on a CNC machine:

1. Work Hardening

Cold rolled steel is hardened through plastic deformation during rolling. This means the surface layer is tougher than you’d expect. Once your cutter breaks through that layer, things often smooth out—but you’ll need good tooling and setup to avoid tool deflection at the start.

2. Surface Finish vs. Tool Life

The smooth surface of CRS looks great, but it’s not tool-friendly. That hardened shell causes more tool wear than softer hot rolled material. Carbide tools and coated end mills (like TiN or TiAlN) make a huge difference.

3. Steel Grade Variance

Not all CRS grades are equal. SAE 1008 cuts easier than Q235, even if both are called “cold rolled.” Lower carbon content usually means better machinability, but also lower strength. There’s always a tradeoff.

Cold Rolled Steel Machinability Ratings

Here’s a rough overview of machinability across different CRS grades, based on my hands-on experience and supported by standard machinability indexes:

| Grade | Relative Machinability (%) | Tool Wear Rate | Recommended Tool Type | Coolant Use |

|---|---|---|---|---|

| SPCC | 45 | Moderate | Coated HSS / Carbide | Optional (light cuts) |

| Q195 | 50 | Low | HSS | Optional |

| Q235 | 55 | Moderate-High | Carbide w/ coating | Recommended |

| SAE 1008 | 60 | Low | HSS / Carbide | Optional |

| SAE 1010 | 65 | Moderate | TiN-coated Carbide | Recommended |

| A366/1008 | 55 | Moderate | HSS | Light lubrication |

These values aren’t fixed—they depend on your setup, toolpath, machine rigidity, and even ambient temperature. But they give a solid starting point.

Personal Machining Notes

I’ve found that cold rolled Q235, though common, is a bit of a tool killer unless you stay on top of your chip evacuation and avoid dry runs. When cutting A366, the finish is beautiful, and you can run light passes with minimal burrs. On the other hand, SAE 1010 needs a sharp tool, and if you dull it mid-cut, you’ll get edge hardening and chatter fast.

One trick I picked up is to run roughing passes just shy of final dimensions, then come back with a fresh finish tool at lower feed to preserve both surface finish and accuracy.

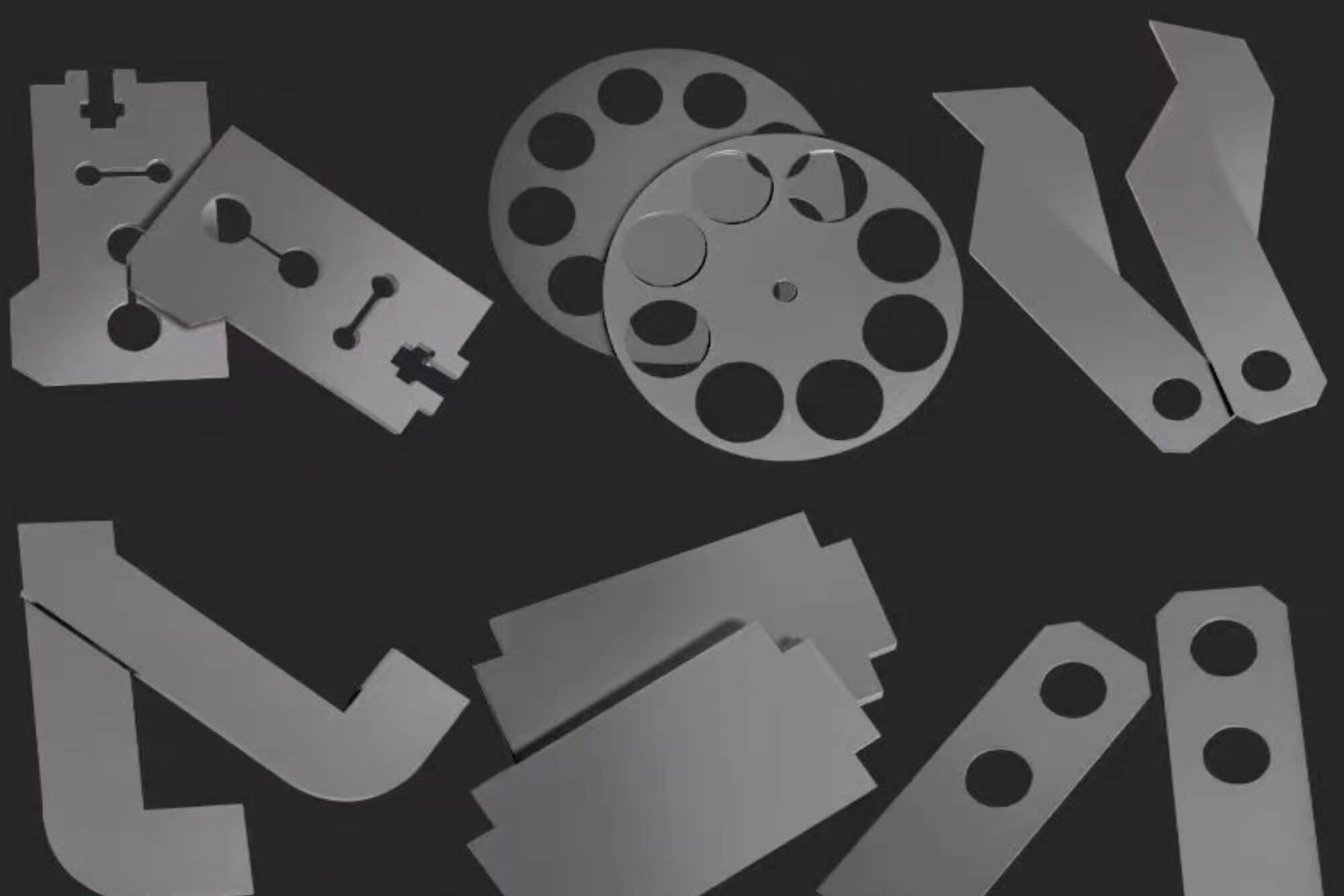

Common CNC Machining Methods for Cold Rolled Steel

Cold rolled steel is one of the most versatile materials I’ve worked with in the shop. Over the years, I’ve machined it using nearly every method you can think of—milling, turning, drilling, and even laser cutting. Each method has its own strengths and considerations when you’re working with cold rolled steel. Choosing the right one often depends on the part’s geometry, tolerance, and volume.

Let’s break them down.

Milling Cold Rolled Steel

This is my go-to method for most CRS parts. Whether I’m working on brackets or panel cutouts, vertical and horizontal CNC mills offer excellent control.

Best Use Cases:

- Flat surfaces and 2.5D profiles

- Pocketing and contouring

- Surface finishing

Tips:

- Use a 4-flute carbide end mill with a TiAlN coating.

- Keep your depth of cut shallow if the steel is not annealed.

- Coolant helps—especially with small end mills.

- Avoid plunge cuts directly into the steel’s surface layer unless you’re using center-cutting tools.

Turning Cold Rolled Steel

On the lathe, cold rolled steel performs well if your tool is sharp and rigid. I’ve turned shafts, spacers, and small bushings out of Q235 and SAE 1008 without trouble.

Best Use Cases:

- Cylindrical components

- Threads and grooves

- Precision diameter control

Tips:

- Use a sharp carbide insert with positive rake.

- Set a consistent feed rate—too slow, and you’ll get built-up edge.

- Don’t skip coolant; dry turning leads to rough finishes on CRS.

Drilling Cold Rolled Steel

Drilling is where I’ve seen the most variation in performance across steel grades. Lower carbon CRS drills clean, but as carbon increases, the hole quality suffers unless you prep well.

Best Use Cases:

- Mounting holes

- Tapping preparation

- Pilot holes

Tips:

- Use cobalt or carbide drills.

- Peck drilling helps reduce heat and chip packing.

- Always spot drill first to keep holes centered.

- Avoid drilling too close to an edge unless properly fixtured.

Laser and Plasma Cutting

This is where cold rolled steel’s clean surface really shines. I’ve used laser-cut CRS blanks for projects where dimensional accuracy and surface finish were top priority before moving to CNC secondary ops.

Best Use Cases:

- Flat sheets

- Custom enclosures

- Pre-fab blanks for secondary CNC work

Tips:

- Make sure the steel is free of scale and oil before cutting.

- Watch for edge hardening, which can affect later milling or tapping.

- Post-cut deburring is often needed, especially on plasma cuts.

Surface Grinding

I don’t use grinding often, but when I need flatness under ±0.01mm, CRS handles it well—especially the softer grades like SPCC.

Best Use Cases:

- Precision tool bases

- Shims and spacers

- Surface finishing prior to coating

Tips:

- CRS can gum up the wheel if it’s not dressed properly.

- Keep the table speed moderate and use coolant generously.

Summary Table: CNC Methods vs. CRS Performance

| Method | Surface Finish Quality | Tolerance Control | Tool Wear | Setup Difficulty | My Notes |

|---|---|---|---|---|---|

| Milling | High | High | Moderate | Medium | Best all-round choice |

| Turning | High | High | Low | Low | Great for shafts, threads |

| Drilling | Medium | Medium | High | Low | Needs good chip removal |

| Laser Cutting | Very High | High | None | Low | Fast, clean, ideal for blanks |

| Plasma Cutting | Medium | Low | None | Very Low | Cheap but rough edges |

| Surface Grinding | Excellent | Very High | Low | High | Good for precision flats |

Cutting Strategies and Tooling Tips for Cold Rolled Steel

If there’s one thing I’ve learned after hundreds of hours machining cold rolled steel, it’s that your tooling and strategy can make or break a job. CRS might seem straightforward at first, but it has a hard outer shell that dulls tools quickly and punishes the wrong feed rates.

In this section, I’ll share what works—and what doesn’t—when it comes to choosing tools, setting cutting parameters, and planning machining strategies specifically for cold rolled steel.

Tool Selection for Cold Rolled Steel

Picking the right tool isn’t just about the brand or shape—it’s about material, coating, and cutting geometry. Here’s what I personally use:

Recommended Tool Types

- Material: Solid carbide > cobalt HSS > regular HSS

- Coatings: TiAlN or TiCN – These coatings improve heat resistance

- Flute Count:

- 2-flute for slotting or softer grades

- 4-flute for general milling

- 6-flute for finishing operations

If I’m roughing out a large Q235 block, I go with a 4-flute carbide end mill with TiAlN. When finishing thin panels or working on small parts, I switch to a sharper, higher-helix tool to minimize vibration and reduce tool pressure.

Cutting Speed and Feed Recommendations

These numbers are my starting point, and I always tweak them based on how the machine reacts. But if you’re working with cold rolled steel, these feed & speed settings will give you a good baseline.

| Tool Type | Steel Grade | Spindle Speed (RPM) | Feed Rate (mm/min) | Depth of Cut (mm) | Notes |

|---|---|---|---|---|---|

| 4-flute Carbide EM | Q235 | 1200–1800 | 200–350 | 0.5–1.5 | Light coolant recommended |

| 2-flute HSS EM | SPCC | 800–1200 | 100–200 | 0.3–0.8 | Use for finishing passes |

| Carbide Drill | SAE 1010 | 2000–3000 | 300–600 | Full drill dia. | Peck drilling for >10mm depth |

| Turning Insert | Q195 | 400–900 | 0.2–0.5 mm/rev | 1–2 mm | Use coolant to improve finish |

EM = End Mill

These values help minimize heat buildup, control chip formation, and extend tool life—all important when working with a material like cold rolled steel that has a work-hardened surface.

Coolant & Lubrication Tips

I’ve machined CRS both dry and wet. Trust me: unless you’re making very shallow cuts, you want coolant—especially for carbide tools.

What Works Best:

- Mist or flood coolant – Keeps chips clear and tools cool

- Oil-based coolant – Ideal for finish operations

- Compressed air – Useful for slotting, but only on soft grades

Without coolant, I’ve seen tools wear out twice as fast, and burrs form along edges that were clean just one pass earlier.

Chip Control and Evacuation

One underrated challenge of machining CRS is chip evacuation. These chips are stringy, hard, and love to wrap around your cutter. I’ve had jobs stall because chips got packed into pockets mid-cut.

Here’s how I handle it:

- Use climb milling whenever possible

- Shorten tool stickout to reduce chatter

- Program chip breaks in long turning passes

- Add air blasts or coolant spray between peck cycles

Finish Quality Tips

Cold rolled steel gives a nice surface if you treat it right. But if your tool is dull or your cut is too aggressive, expect chatter, rubbing, or visible tool marks.

Here’s what works for me:

- Keep finishing passes shallow (0.2–0.5mm)

- Reduce feed rate by 30–50% during final pass

- Always use a fresh or lightly-used tool for finishing

- Deburr with a soft wheel or by hand for precision parts

Application Scenarios in Industry

In nearly every CNC shop I’ve worked in—whether a small prototype garage or a mass-production facility—cold rolled steel is one of the most common materials you’ll find stacked by the wall. It’s affordable, looks good, and behaves predictably once you understand its quirks. But what really sets CRS apart is how well it fits into a wide range of industrial applications.

Here are the places I’ve personally seen cold rolled steel used most effectively.

Electronics Housings and Enclosures

Cold rolled steel is a top choice for electronic equipment frames, control panels, and junction boxes. Its smooth surface makes it ideal for powder coating or painting, and it’s strong enough to hold up in harsh environments.

Why CRS is ideal:

- Good electromagnetic shielding

- Tight dimensional stability for modular designs

- Surface finish looks premium after coating

Real example:

We built a set of custom CNC-machined enclosures for a battery management system using SAE 1008. The parts were laser cut, then machined and tapped. The clean CRS surface made powder coating flawless.

Automotive Brackets and Structural Supports

From radiator mounts to seat brackets, CRS finds its way into automotive components that require high strength and manufacturability. I’ve machined cold rolled Q235 into dozens of parts for aftermarket racing builds.

Advantages:

- Great strength-to-cost ratio

- Easy to weld and finish

- Works well with laser cutting + CNC finishing

Appliance Components

Many white goods—like washing machines, dryers, and ovens—use CRS for both internal frames and outer panels. The dimensional consistency of CRS allows for tight fits and secure mountings, especially when you’re drilling or tapping into it.

Components include:

- Mounting plates

- Door hinges and brackets

- Rear panels with cooling vents

Custom Fabrication and Sheet Metal Jobs

This is where I see cold rolled steel shine the most in CNC prototyping. When someone brings in a new design, CRS is often the first test material—mainly because it’s cheap, available, and reliable.

Used for:

- Prototypes and fixtures

- Custom brackets or mounts

- Low-volume industrial parts

My experience:

I once worked on a custom automation fixture where the client wanted aluminum. But aluminum warped under heat during machining. We switched to CRS, and the part came out flat, tight, and stable—even after welding.

Furniture and Architectural Hardware

Surprisingly, cold rolled steel isn’t just for utilitarian parts. I’ve seen it beautifully integrated into modern furniture—like table legs, brackets, and industrial shelving. Machined edges look clean, and the steel finishes beautifully with patina, paint, or powder.

Example:

A local designer brought in flat CRS panels that we machined with decorative cutouts using CNC plasma, then hand-ground the edges for a brushed finish. The look was sleek and strong—and far cheaper than stainless.

Application Matrix

| Industry | Common CRS Use | Grade(s) Used | CNC Method | Surface Treatment |

|---|---|---|---|---|

| Electronics | Housings, enclosures | SAE 1008 | Milling, drilling | Powder coating |

| Automotive | Brackets, mounts, supports | Q235, 1010 | Laser + machining | Painting, e-coat |

| Appliances | Panels, internal frames | SPCC, Q195 | Punching + milling | Enamel, zinc coat |

| Furniture/Interior | Braces, frames, design elements | Q195, SPCC | Plasma, laser cut | Clear coat, patina |

| Custom Fabrication | Fixtures, prototypes | Any | Milling, turning | Optional |

Industry Case Studies

Nothing teaches you about cold rolled steel like real-world jobs—under deadlines, budget constraints, and the need to “get it right the first time.” Over the years, I’ve had more than my fair share of CRS machining projects across multiple industries. Some went off without a hitch, others taught me hard lessons.

Let me walk you through a few that stand out.

Case Study 1: CNC Battery Enclosure for EV Start-Up

Industry: Electronics / Electric Vehicles

Material Used: SAE 1008 cold rolled steel

Processes: Laser cutting, CNC milling, tapping, powder coating

We were tasked with making a compact battery housing for a small EV company. The enclosure had to be watertight, EMI-resistant, and aesthetically clean.

Key Specs:

- Wall thickness: 2.0mm

- 0.2mm tolerance on machined edges

- 24 threaded holes in each housing

Challenges:

We initially ran the parts dry and noticed poor thread quality. Switching to mist coolant and using TiCN-coated taps resolved the issue. A roughing pass followed by a finishing contour also improved fit with mating parts.

Result:

Parts were delivered on time with under 2% scrap rate, and the client came back with a second order two months later.

Case Study 2: High-Precision Fixture for Automation Line

Industry: Industrial Equipment

Material Used: Q235 cold rolled steel

Processes: CNC milling, surface grinding, reaming

This was a high-tolerance fixture block for holding injection-molded parts during inspection. The customer specified ±0.01mm flatness and burr-free holes.

Challenges:

The Q235 workpiece warped during dry milling. We later discovered that residual stress in CRS can cause distortion if not released properly. The fix? We roughed the part, stress-relieved it with a low-temp anneal, and then did the finishing pass.

Lessons Learned:

CRS needs to “relax” between roughing and finishing if dimensional stability is key.

Case Study 3: Interior Hardware for Custom Home

Industry: Architecture / Interior Design

Material Used: SPCC cold rolled steel

Processes: CNC plasma cutting, hand deburring, powder coating

A boutique design firm needed 100+ bracket sets for wall-mounted shelving. They wanted a “matte black industrial look,” but machining finish had to be clean for visible surfaces.

Key Requirements:

- Smooth outer edges, no visible tooling marks

- Consistent dimensions across all brackets

- Decorative radius cutouts

We used plasma to cut bulk shapes and CNC-milled the decorative edges. Hand sanding and tight inspection ensured no blemishes. The powder coat finish made the parts look almost like anodized aluminum—but with steel’s strength.

Customer Feedback:

“They look like they were built by a luxury brand.”

Case Study Performance Table

| Case | Application | Grade | Issue Faced | Solution Applied | Result |

|---|---|---|---|---|---|

| 1 | Battery housing | SAE 1008 | Thread wear | Coolant + coated taps | High-quality finish, repeat order |

| 2 | Precision fixture | Q235 | Warping after milling | Stress relief + finishing pass | ±0.01mm flatness achieved |

| 3 | Decorative brackets | SPCC | Visible tool marks | Hand sanding + CNC detailing | Premium appearance, happy client |

Material Selection and Sourcing Tips

If you’ve ever stood in front of a metal rack trying to decide between Q195 and SAE 1008, you’ll know what I mean when I say that choosing the right cold rolled steel is a real decision—not just a checkbox. The material you choose affects everything: how well it cuts, how the part finishes, how it behaves under stress, and even how your customer sees the final product.

Here’s what I’ve learned about picking and sourcing the right cold rolled steel for CNC projects.

How to Choose the Right Cold Rolled Steel Grade

There are dozens of CRS grades, but I’ve found that five or six cover 90% of real-world jobs. I use a few rules of thumb to make the decision:

Match the steel to the job:

| Requirement | Recommended Grade | Why? |

|---|---|---|

| High formability | SPCC, A366 | Soft and ductile, ideal for bends and forming |

| Strength without brittleness | Q235 | Balanced mechanical properties |

| Fine threads and tapping | SAE 1010 | Cleaner edge retention, less burr |

| Aesthetic finish needed | SAE 1008 | Surface takes powder coat well |

| Budget-friendly prototyping | Q195 | Cheap, easy to find, good enough for low-risk parts |

These rules save time, especially when you’re balancing cost vs. performance. For example, I wouldn’t waste SAE 1010 on a one-time fixture, but I’d absolutely spec it for precision thread plates.

Domestic vs. Imported CRS: What to Watch For

Not all cold rolled steel is made equal—even within the same grade. I’ve used imported Q235 that behaved more like hot rolled in machining. The chemistry was technically right, but the consistency was off.

Things I always check:

- Mill certificate (MTC) – tells you the exact composition

- Batch variation – ask suppliers if they mix stock

- Surface finish inspection – mill finish can vary, especially with bulk supply

When possible, I ask for samples—especially if it’s a new supplier. I’d rather burn 30 minutes testing it than kill a $200 end mill later.

What to Ask Your Supplier

Whether I’m buying from a big distributor or a local shop, I ask these 5 questions:

- What’s the mill source of this batch?

- Is it annealed or full-hard?

- Do you have cutting services (e.g. shearing, laser)?

- Can you guarantee thickness and flatness tolerance?

- Can I inspect or return for material inconsistency?

These questions save headaches later, especially for tight-tolerance CNC parts.

Where I Source My CRS

Over the years, I’ve worked with a mix of local steel yards and national suppliers. Here’s a breakdown of what works best for each type of order:

| Type of Need | Best Source | Why |

|---|---|---|

| Small-batch/prototype | Local steel yard | Fast turnaround, negotiable pricing |

| Bulk sheet stock for enclosures | National distributor | Guaranteed consistency, MTC included |

| Precision-cut blanks | Laser cutting shop | CNC-ready shapes save machining time |

| High-grade or specialty CRS | Specialty mills | Certified quality, tight specs |

When I’m running a job with tight deadlines, I usually pay a little extra to have the material pre-cut by the supplier. Less time on prep means more time machining.

CRS Selection Decision Matrix

| Application Type | Tolerance Required | Aesthetic Needed | Budget Priority | Recommended Grade |

|---|---|---|---|---|

| Brackets (functional) | Medium | Low | High | Q235 or Q195 |

| Covers/Enclosures | High | High | Medium | SAE 1008 |

| Welded Frames | Low | Low | High | SPCC |

| Tapped plates | High | Medium | Medium | SAE 1010 |

| Sheet prototype | Medium | Medium | Very High | A366 or Q195 |

Process Optimization and Troubleshooting

Even when you pick the perfect cold rolled steel, use the right tools, and program your CNC precisely, things can—and do—go wrong. Over the years, I’ve run into plenty of problems: unexpected warping, burrs that wouldn’t quit, and tool chatter that ruined surface finishes. The good news is that most of these issues follow patterns. Once you know what to look for, they’re usually fixable.

This section is all about solving those problems and optimizing your workflow for smoother, cleaner, and faster results when machining cold rolled steel.

Common Problems When Machining Cold Rolled Steel

Let’s start with the top machining issues I’ve seen—and what to do about them.

1. Excessive Tool Wear

Cold rolled steel has a work-hardened outer shell. If you use uncoated HSS or run dry, tools will dull fast.

Fixes:

- Use TiAlN or TiCN-coated carbide tools

- Apply mist or flood coolant

- Reduce spindle speed if overheating is observed

2. Chatter and Vibration

Often shows up during finishing passes or when cutting thin-walled sections.

Fixes:

- Shorten tool stick-out

- Increase rigidity with proper fixturing

- Use a higher helix tool to reduce cutting force

- Switch to climb milling when possible

3. Workpiece Warping

CRS can retain internal stress, especially in thicker parts. This stress may release unevenly during machining.

Fixes:

- Use a stress relief anneal after roughing

- Mill in multiple light passes

- Leave material on key surfaces for finishing later

4. Burrs and Edge Tearing

Happens a lot with drilling and slotting in low-carbon CRS grades.

Fixes:

- Use sharp, well-ground tools

- Run a separate finishing pass

- Use chamfer tools on edges prone to burring

- Deburr manually or with soft media tumblers

5. Inconsistent Surface Finish

May be caused by tool wear, wrong feed/speed, or a dirty work surface.

Fixes:

- Check for wear on finishing tools

- Lower feed rate for final pass

- Clean vise and bed before setup

- Use lubrication on final passes

Optimization Tips That Work

I’ve experimented with lots of small tweaks over time that added up to smoother operations. Here are a few that made the biggest difference:

1. Rough + Rest

Always separate your roughing and finishing steps. I’ll usually rough a part and let it “rest” for an hour or overnight before doing finishing passes—especially if tight tolerances matter.

2. Light Finishing Passes

For critical surfaces, keep your final pass shallow—around 0.2mm or less. Go slower and use a newer tool.

3. Use Chip Breakers or Spiral Toolpaths

Don’t let chips bunch up in deep pockets or slots. Program chip-breaking retracts or spiral ramp-ins to keep things clean.

4. Pre-check CRS Sheet for Flatness

If you’re starting with cold rolled sheet or plate, lay it flat on the table and check for warping. Even minor waves can throw off accuracy when clamped.

5. Tapping? Go Coated or Go Home

I’ve broken more taps in CRS than any other material. Always use coated taps (preferably spiral flute) and use tapping fluid or mist coolant.

Troubleshooting Quick Reference Table

| Symptom | Likely Cause | Solution |

|---|---|---|

| Tools dulling too fast | Work-hardened surface | Use coated carbide + coolant |

| Chatter during finishing | Poor fixturing or long tool | Shorten stick-out, switch to climb mill |

| Warping post-machining | Internal stress | Pre-rough + stress relieve |

| Burrs on drilled holes | Dull drill, wrong feed | Sharp drill, slower feed + peck |

| Scratches on finish | Dirty setup surface | Clean bed/vise, isolate chips |

Summary and Reference Sheet

After years of machining all kinds of materials—from aluminum to stainless—I keep coming back to cold rolled steelfor its balance of strength, cost, and reliability. Sure, it has its quirks. But when you know how to approach it—from choosing the right grade to dialing in your cut speeds—it becomes one of the most dependable materials you can put on a CNC table.

Let’s wrap this up by reviewing the essentials and sharing a quick reference sheet that I personally use in my own projects.

Key Takeaways

- Cold rolled steel is more stable and has a better surface finish than hot rolled steel, but it’s also harder on tools.

- Grades like SAE 1008 and SPCC are ideal for parts requiring good finish and formability.

- Use coated carbide tools, apply coolant, and separate roughing and finishing passes for best results.

- Avoid skipping stress relief on thick CRS components to minimize warping.

- Don’t underestimate sourcing—consistency and quality from your steel supplier can make a huge difference.

Cold Rolled Steel CNC Quick Reference Sheet

This is the table I keep on my shop wall—easy to glance at before programming or quoting a job.

📋 Machining Parameters by Grade

| Grade | Common Use | Tool Material | Spindle Speed (RPM) | Feed Rate (mm/min) | Coolant Use | Notes |

|---|---|---|---|---|---|---|

| SPCC | Panels, brackets | HSS or carbide | 1000–1500 | 200–300 | Optional | Easy to form, burrs with dull tools |

| Q195 | Prototypes, supports | HSS | 900–1200 | 150–250 | Optional | Cheapest, decent machinability |

| Q235 | Structural parts | Coated carbide | 1200–1800 | 250–350 | Recommended | Hard outer shell, stress relief helps |

| SAE 1008 | Electronics enclosures | Coated carbide | 1500–2200 | 300–400 | Recommended | Great for finish and paintability |

| SAE 1010 | Tapped components | TiN-coated carbide | 1400–2000 | 200–350 | Required | Strong but can work harden quickly |

| A366 | Deep-draw forming parts | HSS or carbide | 1200–1800 | 250–300 | Optional | Softest CRS grade, great formability |

🧰 Tool & Strategy Recommendations

| Operation | Recommended Tool Type | Feed Strategy | Notes |

|---|---|---|---|

| Face milling | 4-flute carbide EM | Climb, full width | Watch out for chatter on long spans |

| Slotting | 2-flute TiAlN-coated | Low DOC, ramp entry | Use air blast to clear chips |

| Drilling | Cobalt or carbide drill | Peck every 2–3× dia depth | Spot first for clean hole start |

| Tapping | Spiral flute tap | Slow RPM, use tap fluid | Never dry tap CRS |

| Thread milling | Single or multi-point EM | Use helical toolpath | Better control than tapping |

FAQ

1. What is cold rolled steel, and how is it different from hot rolled steel?

Cold rolled steel is made by rolling steel at room temperature after it’s been hot rolled. This gives it a smoother surface, tighter tolerances, and higher strength. Unlike hot rolled, it’s better for precision CNC work.

2. Is cold rolled steel harder to machine?

Yes, slightly. The outer surface is work-hardened, which increases tool wear. But with the right tools and speeds, it machines just fine.

3. Which cold rolled steel grade is best for CNC machining?

SAE 1008 and SPCC are great for general-purpose parts. If you need better strength or thread-holding, go with SAE 1010 or Q235.

4. Can I dry machine cold rolled steel?

I wouldn’t recommend it. While it’s possible, tool life drops fast. A little mist coolant goes a long way.

5. What’s the best tool coating for CRS?

TiAlN or TiCN. They handle heat and reduce friction, especially helpful with CRS’s tough outer layer.

6. How do I stop my tools from dulling so fast?

Use coated carbide, keep feeds and speeds within range, and avoid plunging directly into the hardened surface.

7. What causes burrs on CRS edges?

Dull tools and aggressive feed rates. Sharp tools and light finishing passes help reduce burrs.

8. Why does CRS warp after milling?

Residual stress from rolling. Fix it by roughing first, then finishing after stress relief or letting the part rest.

9. Is cold rolled steel good for precision parts?

Yes, especially with its dimensional stability and surface finish. I’ve used it for tight-tolerance fixtures with success.

10. Can I laser cut CRS before CNC machining?

Absolutely. Just watch out for hardened edges, which may need cleanup before milling or tapping.

11. How do I get a better surface finish on CRS

Use sharp tools, reduce feed rate on final passes, and always run a separate finishing pass.

12. Can CRS be welded after CNC machining?

Yes, most grades weld well. Just make sure to clean the surface and remove any cutting oil or coatings.

13. How deep can I drill in CRS before pecking?

I usually peck every 2–3x drill diameter, especially with smaller bits. Helps with chip evacuation and heat.

14. What’s better: tapping or thread milling in CRS?

Tapping is faster, but thread milling gives better control and is safer on high-cost parts.

15. Should I choose CRS or aluminum for my project?

If you need strength, go with CRS. If weight is the issue, aluminum wins. CRS is also better for welding and durability.

16. Can CRS be heat-treated?

Some grades can be case hardened, but most CRS isn’t designed for full heat treating like tool steel.

17. What tolerances can I hold with CRS on a CNC mill?

With proper fixturing and tools, ±0.05 mm is easy. Tighter tolerances (down to ±0.01 mm) are possible with surface grinding or finishing strategies.

18. Where should I buy cold rolled steel?

Local steel yards are great for small jobs. For consistent quality, I go with certified distributors or specialty metal suppliers who provide mill test reports.

Further Reading and Authoritative References

To deepen your understanding of cold rolled steel and its machining processes, consider exploring the following reputable sources. These references offer comprehensive insights into the properties, applications, and machining techniques of cold rolled steel:

- ScienceDirect: Cold Rolling Overview

An in-depth exploration of the cold rolling process, detailing how it enhances metal strength through strain hardening and its impact on mechanical properties.

https://www.sciencedirect.com/topics/chemistry/cold-rolling - Engineering ToolBox: Thermal Expansion of Metals

Provides detailed data on the thermal expansion coefficients of various metals, including cold rolled steel, which is crucial for understanding dimensional changes during machining.

https://www.engineeringtoolbox.com/thermal-expansion-metals-d_859.html - ResearchGate: Numerical Simulation and Experimental Investigation of Cold-Rolled Steel Cutting

This study offers insights into the cutting mechanisms of cold rolled steel, combining numerical simulations with experimental data to improve machining strategies.

https://www.researchgate.net/publication/326574183_Numerical_Simulation_and_Experimental_Investigation_of_Cold-Rolled_Steel_Cutting - ScienceDirect: Cutting Forces during Orthogonal Machining Process of AISI 1018 Cold Rolled Steel

An analysis of cutting forces experienced during the orthogonal machining of AISI 1018 cold rolled steel, providing valuable data for optimizing machining parameters.

https://www.sciencedirect.com/science/article/pii/S2214785317314888 - Wikipedia: Cold-Formed Steel

An overview of cold-formed steel, discussing its manufacturing processes, applications, and advantages in various industries.

https://en.wikipedia.org/wiki/Cold-formed_steel - Wikipedia: Machinability

Explores the concept of machinability, including factors that affect the ease of machining metals like cold rolled steel.

https://en.wikipedia.org/wiki/Machinability

Other Articles You Might Enjoy

- Balancing Strength and Machinability: Cold Rolled vs. Hot Rolled Steel in CNC Manufacturing

Introduction to Cold Rolled and Hot Rolled Steel in CNC Manufacturing In the world of Computer Numerical Control (CNC) manufacturing, two types of steel mainly dominate the scene - cold…

- Corten Steel for Designers: Creative CNC Applications and Cutting Techniques

Why Designers Love Corten Steel When I first worked with Corten Steel, I didn’t expect a rusty-looking material to be so beautiful, practical, and in demand. But over the years,…

- Is Surgical Steel CNC Machining-Friendly? Material Properties and Machining Challenges Explained

Is Surgical Steel CNC-Friendly? I still remember the first time I clamped a bar of surgical steel into a CNC mill. It looked just like any other stainless steel—shiny, dense,…

- 18/8 Stainless Steel Machining Guide: Everything You Need to Know

I. Introduction If you've worked with stainless steel before, you've probably come across the term 18/8 stainless steel. It's one of the most common stainless alloys used in CNC machining—and for…

- 18/0 Stainless Steel Machining: Performance, Parameters, and Use Cases

Introduction Working in manufacturing and materials engineering for over a decade, I’ve seen trends rise and fall. One that’s recently caught my attention—and many in our field—is the growing interest…

- Can You Machine Spring Steel? A Complete Guide for Engineers and Machinists

What Is Spring Steel and Why Does It Matter? “Can you machine spring steel?”That was the exact question I asked myself years ago when I got handed a drawing for…

- Custom Stainless Steel Screws with CNC Machining: Techniques, Tools, and Tips

Introduction I first realized how crucial Stainless Steel Screws are in CNC machining projects when I worked on a small manufacturing assignment.We needed durable, corrosion-resistant fasteners for an outdoor piece of equipment,…

- Stainless Steel Fasteners: What Designers and CNC Machinists Must Know

Why Stainless Steel Fasteners Matter in CNC Applications As someone who has spent significant time around CNC machines and designing mechanical assemblies, I've learned one critical truth: the smallest parts…

- Alloy Steel Machining Insights: Your One-Stop Guide to Superior Results

Introduction I’ve always found “alloy steel” to be a fascinating subject. There’s so much depth to it, from its versatile chemical composition to the countless industrial applications that rely on…