Introduction to CNC Machining

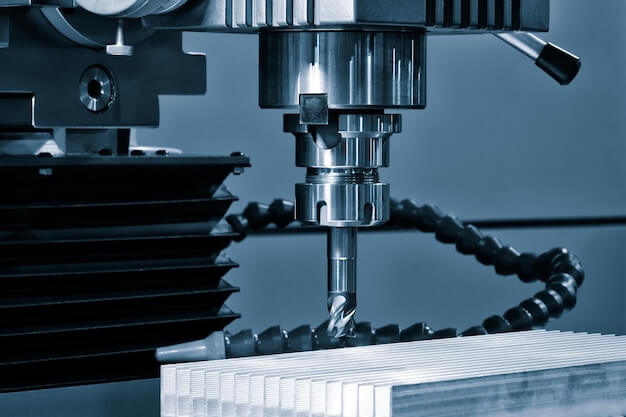

CNC machining, an acronym for Computer Numerical Control, is a process used in the manufacturing sector involving the use of computers to control machine tools. These tools can include lathes, mills, routers and grinders. The precision offered by this technology makes it ideal for producing high-volume aluminum parts; significantly reducing error rates compared to manual operations.

- Accuracy: The precise nature of CNC machining ensures consistent quality with each part produced, making it highly suited for large-scale production of aluminum components.

- Speed: Besides accuracy, CNC machines are also noted for their speed, able to manufacture high volumes in relatively short time periods.

- Economy: In addition to increased productivity and reduced errors, using CNC machines results in lower operating costs as well—making mass production more economically feasible.

The Need for Affordable CNC Machining Solutions

In the pursuit of manufacturing high-volume aluminum parts, one significant economic hurdle is the hefty cost associated with procuring CNC machines. These cutting-edge devices generally have a high initial investment, along with maintenance costs, which could be financially demanding for companies, particularly for small and medium enterprises. The expense is not limited to machine procurement alone, but also encompasses factors such as workforce training, routine upkeep, tooling replacements, and energy consumption.

That said, discovering affordable solutions becomes paramount in ensuring profitability and sustainability. Lower-cost CNC machining solutions allow businesses to scale production while maintaining quality control efficiently. They create an avenue for increased productivity without causing extensive financial strain. For example, adopting a leasing model or sourcing refurbished equipment can significantly mitigate upfront costs, making advanced technology accessible even to smaller manufacturers.

- High initial purchase price

- Workforce training expenses

- Routine maintenance costs

- Tool replacement and upgrades

- Energy bills

Affordable CNC machining solutions are essential in developing an optimal balance between manufacturing capacity, product quality, and operational expenditure, thus propelling competitive advantage and business growth.

The benefits of using CNC machining for aluminum parts are:

- High precision and accuracy in producing intricate designs

- Ability to create lightweight parts, suitable for various applications

- Efficient production process, leading to quick turnaround times

- Cost-effectiveness, especially for high-volume production

- Capability to experiment with different designs and rapid prototyping

Exploring Cost-Effective CNC Machining Solutions

In today’s market, numerous affordable and accessible options are available for high-volume aluminum parts manufacturing using Computer Numerical Control (CNC) machining. These include economical solutions like small-bed milling machines, turning centers, or router-based systems. Additionally, hybrid machine tools that combine additive and subtractive manufacturing methods offer cost-effectiveness on more complex projects. The key factors influencing the economic viability of a solution include initial investment in machinery, running costs, maintenance expenses, labor efficiency, waste management, and lifespan of the equipment. Also, replacing expensive manual work with automated processes can cut down overall production costs.

- Small-bed milling machines: A compact option ideally suited for producing smaller components at lower quantities.

- Turning Centers: This solution provides high-speed precision cutting for larger runs while keeping operation costs comparatively low.

- Router-based Systems: Ideal for carving intricate designs into aluminum fittings without breaking the bank.

- Hybrid Machine Tools: Combines the best features of various machine tools to handle complex, diverse tasks efficiently.

Choosing an Affordable CNC Machinery Solution

When looking to invest in cost-effective CNC machinery, there are several criteria one must consider. First and foremost, ensure the machine has high performance characteristics such as precision, speed, and reliability. Researching these features will provide insight on its ability to produce high-volume aluminum parts without any lapses in quality.

Affordability does not equate to poor quality; instead, it’s about finding a balance between price and value. There’s no need to compromise either while sourcing for the right machinery. Always review the overall build quality, warranty offers and after-sales service before making a purchase.

Going cheap might mean high maintenance costs, poor customer service or downtime, which could end up being more expensive in the long run.

- Determine your requirements: What type of tasks will the machine perform? How much productivity is needed?

- Look at lifecycle cost versus initial investment. Expensive machinery may have lower operating costs over time.

- Analyze supplier reputation – a reputable supplier often provides better post-sale support and assistance with operational issues.

In conclusion, choosing an affordable CNC solution requires careful consideration both in terms of immediate upfront costs and potential future expenses. That way, you can secure durable, efficient machinery that meets your manufacturing needs and also makes economic sense.

Successful Implementation of Affordable CNC Machining for High Volume Aluminum Parts

In an industrial landscape where efficiency is paramount, the benefits of affordable CNC machining for high volume aluminum parts cannot be overstated. A prime example being a custom-made automotive company that previously relied on costly and time-heavy manual labor methods to produce car components. After switching to an affordable CNC machine solution, they were able to drastically increase their production rate while maintaining precision quality.

- The first substantial impact was a significant reduction in production times, leading to faster order fulfillment.

- Secondly, with its automated operation, the number of human errors diminished substantially minimizing wastage and increased yield.

- Lastly, by eliminating the need for continual personnel supervision it reduced operational costs.

This implementation revolutionized the company’s overall business operations creating a ripple effect from manufacturing stages through to customer satisfaction.

Future Outlook: Could Affordable CNC Machining be Efficient?

The efficiency of affordable Computer Numerical Control (CNC) machining in producing high-volume aluminum parts is underpinned by several critical factors. One such factor being the precision of the machine which influences product quality and waste reduction, making it a vital element for consideration.

- An efficient CNC machine reduces production time, thereby improving productivity through optimized tool paths that significantly cut down on unnecessary movements.

- Adopting advanced technologies like automation can boost the effectiveness of these machines to handle large-scale production while maintaining consistency in operations even with minimised human intervention.

- Furthermore, well maintained equipment plays a pivotal role in not just prolonging its lifespan but also in enhancing overall operational efficiency.

Thus, effective utilization of CNC machines requires best practices like regular maintenance programs for optimal functioning; strategic programming for reduced machine idle times; and ongoing systems monitoring, all contributing towards achieving cost-effective yet superior-quality output. Undoubtedly, the emergence of technologically advanced, financially accessible CNC machining offers promising potential for an increasingly efficient future in the manufacturing industry.

Other Articles You Might Enjoy

- Choosing the Right CNC Machining Shop: Factors to Consider

Choosing the Right CNC Machining Shop: An Introduction In today's advanced manufacturing environment, Computer Numerical Control (CNC) machining plays a significant role. CNC machining is a process utilized in the…

- Understanding CNC Machining: MIG vs. TIG Welding and more( cnc machining services china Julie)

Computer Numerical Control (CNC) machining has remarkably revolutionized the manufacturing industry by offering precise, efficient, and versatile solutions that cater to a range of products. Within this realm of production…

- Precision CNC Machining for the Telecommunications Industry

Introduction to Precision CNC Machining in Telecommunications The use of Computer Numerical Control (CNC) machining has become a cornerstone in manufacturing industries, offering flawless precision and increased efficiency. The nuanced…