Introduction to IoT

The Internet of Things, commonly referred to as IoT, is a revolutionary concept where everyday objects are interconnected through the internet, enabling them to send and receive data. This network of physical devices extends beyond standard items like computers and smartphones, encompassing a diverse array of equipment such as home appliances, vehicles, thermostats, and wearable technology—all equipped with embedded sensors, software, and other forms of connectivity. These connected gadgets can collect data, act upon it, and communicate with each other within their ecosystems. For instance, a smart thermostat can adjust heating or cooling by analyzing real-time environmental data from sensors or user-set preferences. The seamless operation of these devices relies on a blend of communication protocols, networking methods, and data analytics platforms, which together form the operational backbone of any IoT system.

Configuration of IoT Devices

The setup process for an Internet of Things (IoT) device involves several key stages, starting with physical assembly and connection to necessary power sources. Next is the installation of firmware or software that dictates the device’s function, followed by configuration to connect securely to a network—typically via Wi-Fi, Bluetooth, or Ethernet. Essential components within this ecosystem include sensors for data collection, actuators for control, microcontrollers for processing, and communication modules for transmitting information. Ensuring robust security protocols during these steps is critical, as compromised devices can risk the integrity of user data and broader network infrastructure. For instance, configuring a smart thermostat not only includes connecting it to the home WiFi but also setting up encryption and authentication methods to prevent unauthorized access.

Advantages of IoT Integration

The integration of IoT technology ushers in significant efficiency improvements through the automation of mundane and routine tasks, allowing systems to operate independently with minimal human intervention. For instance, in a smart factory setting, sensors can monitor production lines, sending real-time data to machine learning algorithms that predict maintenance needs before a breakdown occurs. This proactive approach minimizes downtime and boosts productivity. Additionally, comprehensive data collection and analysis become pivotal for strategic decision making, offering insights into consumer behavior, supply chain logistics, or energy consumption patterns. Businesses harness this information to refine processes, increase their market competitiveness, and drive innovation. The user experience also benefits from IoT advancements as smart devices provide personalized interactions, adapting to individual preferences and behaviors, enhancing comfort, and convenience in both domestic and commercial environments.

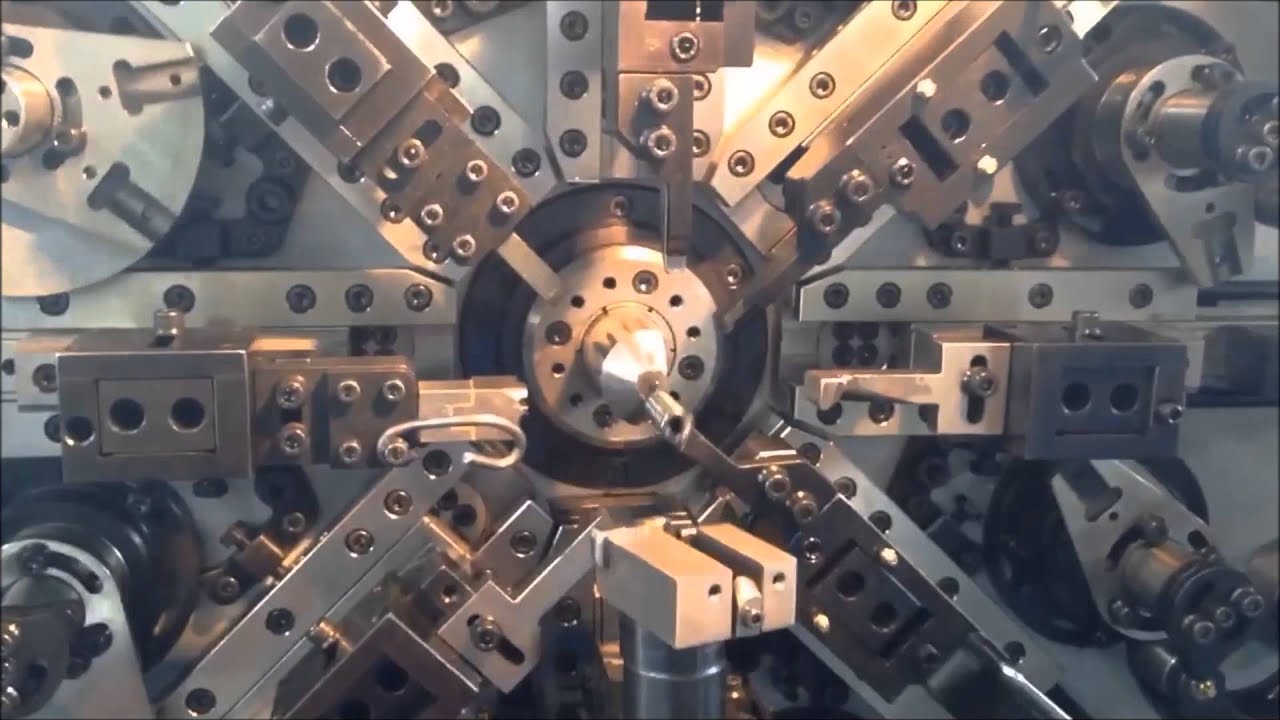

Industrial IoT Applications Optimizing Production Processes

The implementation of the Industrial Internet of Things (IIoT) has revolutionized production processes by introducing smart manufacturing facilities that autonomously monitor and adjust operations for efficiency. A pivotal component in this ecosystem is the network of sensors and actuators embedded into machinery, which collects real-time data on performance metrics such as temperature, pressure, and output rates. This information streams to a centralized analytics platform where algorithms analyze trends and prescribe adjustments to optimize energy use, reduce waste, and preempt maintenance needs. Moreover, IIoT incorporates advanced robotics that interact with systems via machine-to-machine communication protocols, further enhancing precision and productivity while enabling human workers to focus on more complex tasks.

The Future of IoT Development

Anticipated advancements in IoT technology are set to revolutionize the interaction between digital and physical worlds, promising a profound impact on multiple industries as well as everyday life. Progress in edge computing will ensure faster processing and response times by conducting data analysis locally on IoT devices rather than relying solely on cloud services. In agriculture, sensors could provide real-time soil conditions leading to more efficient water usage and crop yield. The healthcare sector may see remote monitoring devices that can predict health episodes before they occur. Moreover, advancements in AI integration within IoT systems are anticipated to bring about smarter automation in manufacturing, enhancing precision and reducing downtime. These futuristic strides aim to create fully interconnected environments where decision-making is more informed, timely, and potentially autonomous.

Q&A Section: Practical Insights into IoT

A. Household Applications of IoT: Smart home assistants have become the most common use of IoT devices in households, facilitating tasks such as controlling lighting and temperature, managing security systems, and integrating with other smart appliances for a unified home automation experience.

B. IoT and Energy Savings: By enabling precise control over heating, cooling, and electricity usage through smart thermostats and energy-efficient bulbs that adjust based on patterns or sensors, IoT contributes to significant energy savings and reduced utility bills.

C. Security of IoT Devices: Yes, IoT devices can be susceptible to hacking; however, risks can be mitigated by implementing robust encryption, regular security updates, secure authentication methods, and educating users about proper device management practices.

D. Business Adoption of IoT for Customer Satisfaction: Businesses are leveraging IoT technology to track inventory in real-time, offer personalized promotions via beacon technology, improve logistics through fleet tracking, and facilitate easier access to customer service, all aimed at enhancing overall customer satisfaction.

E. IoT Evolution and 5G: With the rise of 5G technology, IoT is set to evolve through improved connectivity speeds, ultra-low latency, and increased network reliability, making it possible for more complex and data-intensive applications like autonomous vehicles and advanced remote healthcare services.

Other Articles You Might Enjoy

- Applications and Advantages of Bronze CNC Machining

1. Introduction: The Enduring Allure of Bronze in CNC Machining In this opening section, we explore the timeless appeal of bronze as a material for CNC machining. From its rich…

- Elevating Industries through the Advantages of China CNC Machining

1. Introduction: Transformative Impact on Industries In this introductory section, we explore how China CNC machining has become a driving force in transforming various industries. We set the stage for…

- Precision Prowess: Unveiling the Advantages of China CNC Machining

1. Introduction: The Role of Precision in Manufacturing Excellence In this introductory section, we delve into the critical role that precision plays in manufacturing and set the stage for an…