Introduction to Delrin

Delrin, a trade name for polyoxymethylene (POM), stands as a groundbreaking synthesis in the world of engineering polymers. Renowned for its high tensile strength, stiffness, and dimensional stability, Delrin is frequently used where precision parts require high resilience and low friction performances. In the realm of plastic innovation, it has carved out its significance by offering an exceptional balance of properties that rival metals in terms of durability and performance. This thermoplastic material is crafted through polymerization of formaldehyde, leading to a substance revered in engineering applications ranging from gear wheels and fasteners to instrument knobs and electrical insulators. Its impact on various industries underscores not only the versatility of plastics but also their potential in replacing traditional materials in advanced engineering solutions.

Historical Background and Key Properties of Delrin

The remarkable plastic known as Delrin was first synthesized by chemists at DuPont in the 1950s. This thermoplastic, officially termed polyoxymethylene (POM), represents a significant advancement due to its superior mechanical properties. Its development marked a transformative shift in materials engineering, providing an innovative solution where metal was once the default choice. What makes Delrin distinct are attributes such as high tensile strength, impressive rigidity, and notable low friction characteristics. These features endow it with excellent dimensional stability and fatigue endurance, making it ideal for precision parts in demanding applications. Furthermore, Delrin boasts a low coefficient of friction and good wear resistance, which explains its widespread use in components where sliding actions are frequent, like gears, bearings, or door systems.

Distinctions and Advantages of Delrin in Engineering Applications

In comparison to other engineering plastics such as Nylon, Delrin distinguishes itself with a unique blend of properties that cater to specific application needs. Unlike Nylon, which is prone to moisture absorption leading to dimensional instability, Delrin boasts superior dimensional stability under varying environmental conditions. This attribute renders it an advantageous option for precision mechanical parts where consistent performance is vital. Additionally, Delrin’s low coefficient of friction coupled with its high wear resistance eclipses those of conventional thermoplastics, making it the go-to material for components like gears and bearings that demand minimal lubrication and long-term durability. These technical advantages clearly illustrate why Delrin is selected over alternatives in applications necessitating accuracy, longevity, and resilience against fluctuating operational environments.

Applications of Delrin in Various Industries

Delrin’s versatility has carved its niche across various industries due to its mechanical properties and resilience. In the automotive sector, it is employed for components like fuel system housings and safety restraint systems where durability and performance are critical; example being its use in seatbelt mechanisms and gear wheels. Shifts into consumer electronics showcase Delrin as an ideal candidate for small, precision parts such as mobile phone assemblies, offering the necessary strength and wear resistance for repeated actions. The material shines in medical devices too, exemplified by applications in insulin pens for diabetic patients, wherein it provides a combination of structural integrity and engineered smoothness vital for patient comfort and device reliability.

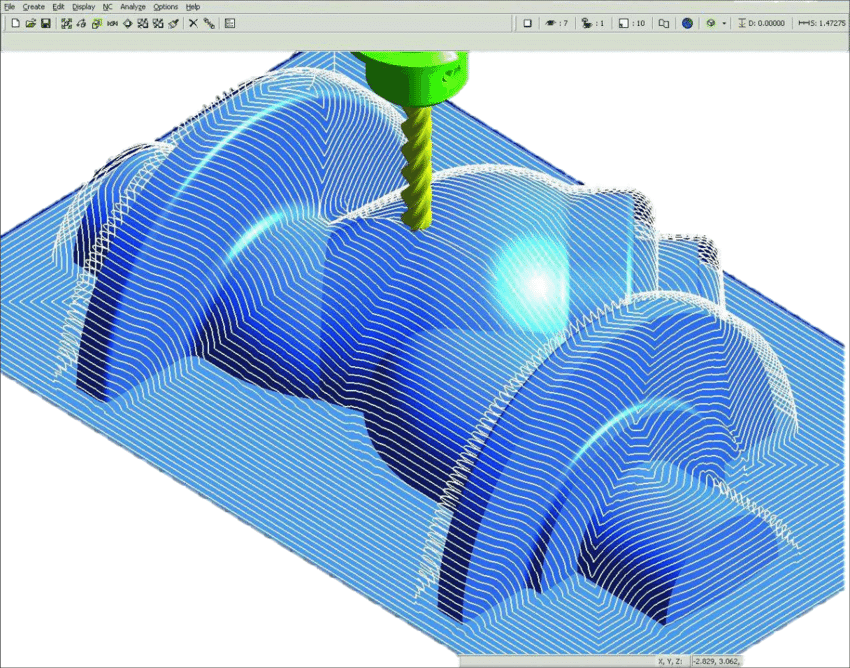

Manufacturing Process and Machinability of Delrin

The engineering plastic Delrin is fabricated primarily through injection molding and extrusion processes. Injection molding involves melting the polymer and injecting it into a mold under high pressure, where it cools and solidifies into the desired shape. Extrusion, on the other hand, pushes melted material through a die to create continuous shapes that can be cut to length. Delrin’s compatibility with these processes, coupled with its ease of machining, affords manufacturers expedited production cycles; tools don’t wear out as quickly when shaping it, and it allows for precise tolerances when fabricating components. This property streamlines manufacturing workflows by reducing downtime for maintenance and facilitating quicker transitions from concept to finalized product.

Environmental Impact and Sustainability of Delrin

The recyclability and environmental considerations for Delrin are essential facets in its sustainability profile. Being a thermoplastic, Delrin can be re-melted and reshaped, offering some potential for recycling. However, the presence of any additives can complicate this process. In response to environmental concerns, measures have been implemented to reduce waste during Delrin production and usage. For instance, efficient design to minimize excess material use and recycling systems within manufacturing processes help conserve resources and energy. An example of such an initiative is ‘closed-loop’ recycling programs that capture post-industrial Delrin scraps, thus diverting them from landfills and reincorporating them into the production cycle. This not only extends the life of the material but also contributes towards circular economy principles by minimizing raw material extraction and reducing overall carbon footprint. Nevertheless, the practical application of these methods depends on local infrastructure and industry practices.

Future Prospects of Delrin

In the realm of engineering plastics, Delrin stands poised for innovative modifications and formulations that aim to further elevate its performance parameters. Researchers are exploring avenues such as nano-composite incorporation which could render the material even more robust in terms of mechanical strength and temperature stability. Moreover, there is potential to expand into new markets such as aerospace and medicine by customizing the polymer’s properties—like enhancing biocompatibility or creating specialized grades with improved fire retardancy or chemical resistance. These advances hold promise for lightweight yet durable components that can withstand challenging environments, thus catalyzing a wave of novel applications across various industries.

Other Articles You Might Enjoy

- Understanding Delrin: A Comprehensive Guide to the Versatile Engineering Plastic

Understanding Delrin and the Role of Engineering Plastics Delrin, formally known as Polyoxymethylene (POM), is an engineering plastic renowned for its high tensile strength, rigidity, and resilience against friction and…

- What Is the Difference Between Acetal Plastic and Delrin?

Brief Overview of Engineering Plastics Engineering plastics are a group of plastic materials that have better mechanical and thermal properties than the more widely used commodity plastics (such as polystyrene,…

- Delrin vs Nylon: Comparing the Properties and Applications of Two Popular Engineering Plastics

Engineering plastics have become foundational materials in the design and manufacturing of an array of components, owing to their mechanical strength, durability, and flexibility. Critical to material selection in engineering…