Surface quality in machining not only affects the appearance of the product but also has a significant impact on its performance, reliability, and durability. Studying and controlling surface quality can improve the surface quality of machined parts, thereby enhancing product performance. In fact, the damage of parts often starts from the surface layer, so the purpose of studying surface quality in machining is to prevent early failure of products and extend their service life.

2. Definition of Surface Quality

Surface quality in machining includes two aspects: geometric characteristics of the surface and physical, mechanical, and chemical properties of the surface layer.

2.1 Geometric Characteristics of the Surface

The shape of the machined surface always deviates from the ideal smooth surface in the form of “peaks” and “valleys.” This deviation can be divided into macroscopic and microscopic cases:

- Macroscopic geometric errors: When the ratio of wavelength (L) to amplitude (H) is greater than 1000 (L/H > 1000).

- Microscopic shape errors: When the ratio is less than 50 (L/H < 50), it is referred to as surface roughness.

- Surface waviness: When the ratio is between 50 and 1000 (50 < L/H < 1000).

Additionally, the surface includes geometric features such as texture direction and defects. Texture direction refers to the direction of surface tool marks, which usually depends on the machining method used. Defects are flaws on the machined surface, such as sand holes, pores, and cracks.

2.2 Physical, Mechanical, and Chemical Properties of the Surface Layer

The physical, mechanical, and chemical properties of the surface layer mainly include surface hardening, metallurgical changes, and residual stresses.

- Surface Hardening: During machining, the surface layer metal undergoes severe plastic deformation, increasing its strength and hardness.

- Metallurgical Changes: During machining, factors such as cutting heat cause changes in the microstructure of the surface layer metal.

- Residual Stresses: The interaction of cutting heat and deformation during machining creates elastic stresses in the surface layer and its boundary with the base material.

3. Impact of Surface Quality on Part Performance

Surface quality significantly impacts the wear resistance, fatigue strength, and corrosion resistance of parts.

3.1 Wear Resistance

Wear of parts can be divided into three stages: initial wear, normal wear, and rapid wear. The effect of surface roughness varies under different load conditions. There is an optimal surface roughness value under certain conditions, usually with an Ra value of about 0.32 to 0.25μm. Excessive surface hardening can lead to loosened metal structure, fatigue cracks, and reduced wear resistance.

3.2 Fatigue Strength

Under alternating loads, surface roughness, scratches, and cracks on parts can lead to stress concentration, which develops into fatigue cracks, causing part failure. Proper surface hardening can hinder the propagation of existing cracks and the formation of new ones, thereby increasing fatigue strength.

3.3 Corrosion Resistance

Larger surface roughness makes it easier to accumulate corrosive substances; the deeper the valleys, the stronger the penetration and corrosion. Residual compressive stress can enhance the corrosion resistance of parts, while tensile stress reduces it.

4. Factors Affecting Surface Roughness and Improvement Measures

The formation and influencing factors of surface roughness can be divided into geometric and physical factors.

4.1 Geometric Factors

Geometric factors mainly include the radius of the tool tip arc, main angle, secondary angle, and feed rate. By choosing the geometric parameters of the tool properly, surface roughness can be effectively controlled. For example, increasing the main angle and front angle of the tool can reduce cutting force, thereby lowering surface roughness.

4.2 Physical Factors

Physical factors include the plastic deformation of the metal surface layer and vibrations during machining. Proper use of cutting fluid can lower the temperature in the grinding area, reducing plastic deformation and improving surface quality. Vibrations during machining significantly affect surface quality; reducing system vibrations and increasing system rigidity can improve the machined surface quality.

5. Measures to Improve and Enhance the Physical and Mechanical Properties of the Surface Layer

Surface strengthening processes involve cold plastic deformation of the surface layer metal to reduce surface roughness, increase surface hardness, and introduce residual compressive stress in the surface layer. These methods are simple, cost-effective, and widely used.

5.1 Shot Peening

Shot peening uses compressed air or centrifugal force to propel a large number of small balls at high speed onto the surface of the part being processed, creating a hardened layer and residual compressive stress on the surface. This significantly improves the fatigue strength of the part. Shot peening is mainly used to strengthen complex-shaped parts such as gears, connecting rods, and crankshafts.

5.2 Rolling Process

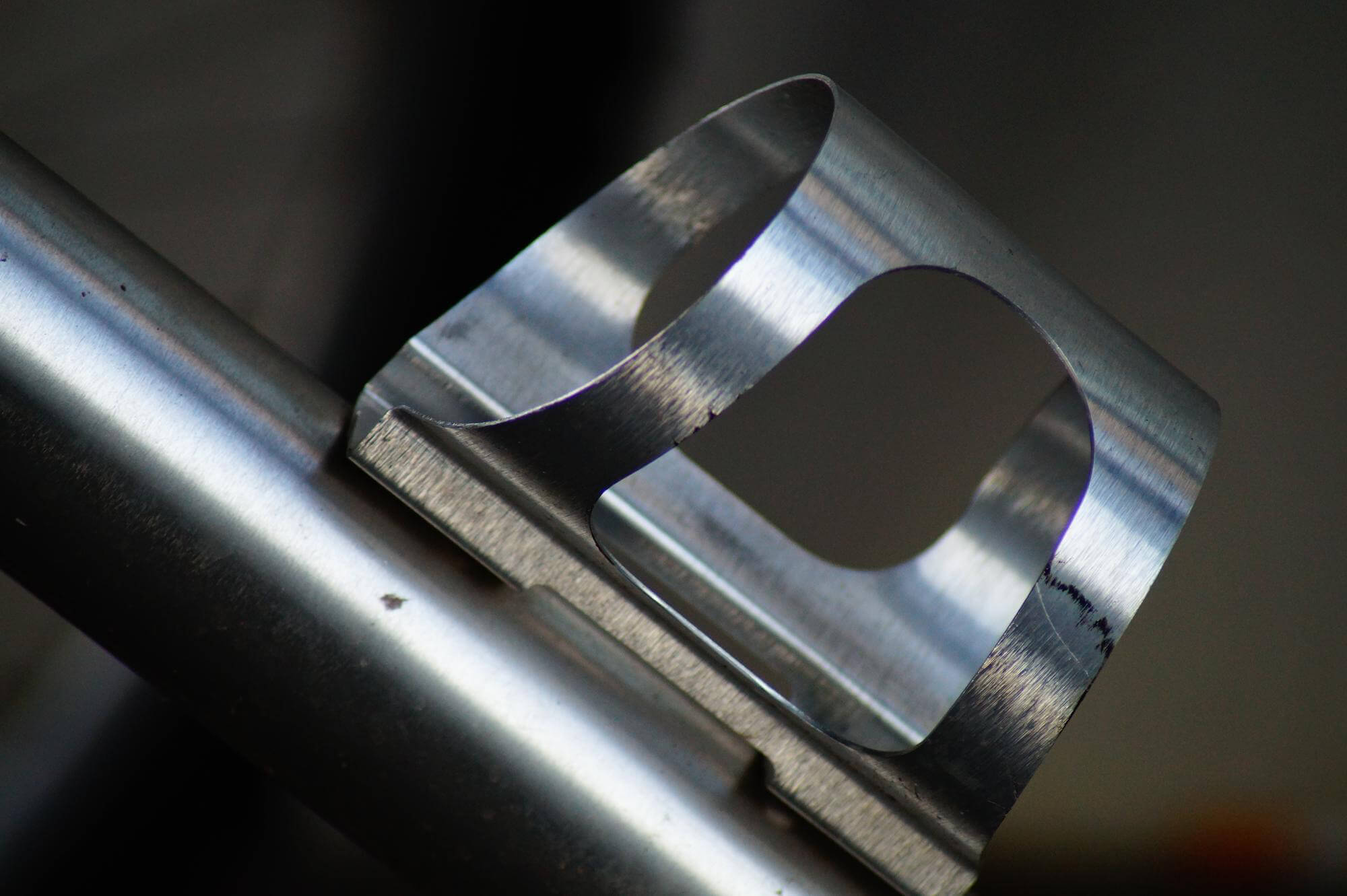

Rolling uses hardened rolling tools to apply pressure to the part surface at room temperature, causing plastic deformation. This reduces surface roughness and creates a hardened layer and residual compressive stress on the surface, improving the part’s load-bearing capacity and fatigue strength. Rolling can process outer diameters, holes, flat surfaces, and formed surfaces and is usually performed on lathes, turret lathes, or automatic lathes.

5.3 Liquid Abrasive Strengthening

Liquid abrasive strengthening involves using a mixture of liquid and abrasives to strengthen the surface of the part. Through the impact of abrasives, the surface roughness of the part is smoothed, and the metal surface is rolled. This process improves the wear resistance, corrosion resistance, and fatigue strength of the part. It is most suitable for processing complex shapes such as forging molds, turbine blades, propellers, instrument parts, and cutting tools.

Data Table

| Processing Method | Surface Hardness Increase (%) | Fatigue Strength Increase (%) | Application Examples |

|---|---|---|---|

| Shot Peening | 30-50 | 50-100 | Gears, Connecting Rods, Crankshafts |

| Rolling Process | 20-40 | 30-50 | Outer Diameters, Holes, Flat Surfaces |

| Liquid Abrasive Strengthening | 40-60 | 60-120 | Forging Molds, Turbine Blades, Propellers |

Conclusion

In conclusion, surface quality in machining greatly affects the performance and lifespan of parts. By properly controlling machining process parameters and choosing appropriate surface strengthening methods, the surface quality of parts can be significantly improved, enhancing their performance and service life. We hope this article provides valuable insights and contributes to the ongoing progress in the field of machining.

4o

Other Articles You Might Enjoy

- Mechanical Machining Surface Quality: From Principles to Practical Application

Mechanical machining surface quality is a crucial aspect of mechanical manufacturing that directly impacts the performance and longevity of parts. This article will discuss the principles, influencing factors, and practical…

- Surface Quality in Machining

Surface quality in machining refers to the overall condition of a part's surface after machining, encompassing its geometric shape, physical-mechanical properties, and chemical properties. Studying and understanding how various process…

- The Role of Ceramic Beads in Achieving Superior Surface Quality in CNC Machining

Introduction to Ceramic Beads in CNC Machining Ceramic beads, known for their hardness and spherical uniformity, have emerged as a pivotal component in CNC machining operations aimed at achieving superior…

- Surface Refinement: Leveraging Bead Blasting for CNC Machining

In the realm of CNC machining, surface quality plays a pivotal role in determining the overall performance and aesthetics of the final product. Leveraging bead blasting as a surface refinement…

- The Dependable Quality Assurance in China CNC Machining

1. Introduction: Setting the Stage for Quality Excellence In this introductory section, we lay the groundwork for an exploration into the world of quality assurance in China CNC machining. We…

- Optimizing CNC Machining Parts Using Constant Surface Speed Techniques

CNC machining, particularly on lathes, can be a complex process, but understanding and utilizing constant surface speed (CSS) techniques can simplify and enhance the efficiency of your operations. The key…