Introduction to Casting in Manufacturing

Casting is a foundational manufacturing process wherein molten material—often metal—is poured into a pre-shaped mold and allowed to solidify, forming a replica of the mold’s internal geometry. This technique enables the production of complex shapes that would be challenging or uneconomical to achieve through other methods. The versatility of casting extends across various industries, allowing for the creation of components ranging from simple household items to critical parts for aerospace applications. Each component within the casting process, such as the furnace for melting materials, molds for shaping, and finishing tools for post-cast processing, plays an essential role to ensure the final product meets design specifications.

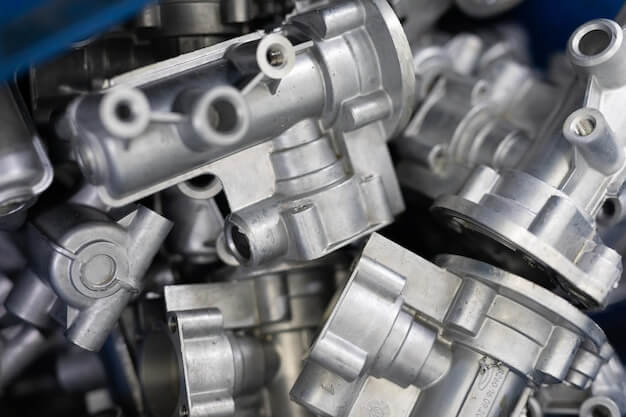

Die Casting

Die casting is a metal casting process characterized by forcing molten metal under high pressure into a mold cavity. The mold, known as a die, is typically made from hardened steel or high-strength aluminum and can be reused to produce numerous castings. This process is favored for its ability to create complex shapes with close tolerances, excellent surface finish, and dimensional consistency, especially suitable for volume production. Metals commonly used in die casting include zinc, copper, aluminum, magnesium, lead, pewter, and tin-based alloys. Once the metal solidifies, the die is opened to eject the casting, and the cycle begins anew. This efficient protocol yields durable components used across various industries, including automotive, aerospace, and electronics.

Investment Casting

Investment casting, also known as lost-wax casting, is a meticulous and precise process utilized for producing finely detailed metal components. The technique starts with creating a wax pattern, which is an exact replica of the desired final product. The wax model is then encased in a ceramic shell that hardens once fired, during which the wax melts away, leaving a perfect mold for casting. Molten metal is poured into this heat-resistant shell, solidifying to form the intricate design initially shaped by the wax. Once cooled, the ceramic mold is broken apart to reveal the metal part inside, which may undergo additional finishing to achieve the necessary specifications. Investment casting is extensively adopted in industries such as aerospace, automotive, and medical devices for its ability to manufacture parts with complex geometries, thin walls, and a smooth surface finish.

Centrifugal Casting

In centrifugal casting, molten metal is poured into a rotating mold, where the centrifugal force distributes the liquid material evenly along the inner surface of the mold. This method exploits the fundamental principle of centrifugal force to shape the casting by generating a pressure that presses the molten material against the mold walls as it solidifies. The result is a dense and clean structure with minimal impurities or inclusions near the surfaces. Centrifugal casting is greatly favored in industries producing cylindrical components such as pipes and bushings for the automotive, aerospace, and military sectors due to its efficiency in manufacturing parts with uniform mechanical properties and refined microstructure.

Permanent Mold Casting

In permanent mold casting, the molds are manufactured from metal and designed for repeated use, which distinguishes this process from sand casting where molds are destroyed after each run. The reusability of these molds means that they must be robust enough to withstand high temperatures and repeated cooling cycles without degrading. Consequently, this method is suitable for producing non-ferrous metal parts – such as those made from aluminum or magnesium alloys – with uniform quality and good dimensional accuracy. Typically, components like automotive pistons, wheels, and housings are cast using this technique due to the durability of the molds and the ability to maintain consistent part quality over numerous production cycles.

Lost Foam Casting Technique

The lost foam casting technique is an innovative foundry process where a foam model, identical to the final product shape, is used as a mold for casting. The unique aspect of this method involves placing the polystyrene foam pattern into a sand container without a traditional flask system. Molten metal is then poured directly into the mold, causing the foam to vaporize and be replaced by the metal, perfectly replicating the desired structure with great accuracy and intricate detail. This process sees frequent application in the production of complex components such as engine blocks and parts that require precision but would be difficult or uneconomical to produce using conventional die-casting methods. Besides its high dimensional accuracy, lost foam casting reduces the need for post-casting machining operations and enables designers to consolidate multiple parts into a single cast component.

Shell Mold Casting

Shell mold casting is a process that involves creating a hardened shell of sand and resin that conforms to the desired part shape. The steps begin with heating a metal pattern which is then coated with a mixture of fine sand and thermosetting resin, forming a half-shell when the mixture hardens upon contact with the hot surface. This procedure is repeated to form another half-shell, allowing both to be joined together to create a complete mold cavity. Molten metal is poured into this cavity, and once cooled, the shell is broken away to reveal the final cast product. Shell molding offers greater precision in dimensional control compared to traditional sand casting due to its smoother mold surface finish and more accurate replicability of the patterns. However, it’s typically more costly than sand casting, but less so than investment casting, striking a balance between cost-effectiveness and detail accuracy for medium to high volume production.

Plaster Casting

Amidst various casting methods, plaster casting stands out for its precision and excellent surface finish. It involves pouring liquid plaster into a mold where it sets and hardens to replicate fine details of the design. The suitability of plaster casting is particularly notable when creating intricate art pieces, detailed prototypes, or tools with a delicate surface that require accuracy without the expense of metallic molds. For instance, in reproducing historical artifacts or detailed architectural elements where the texture and subtleties need to be preserved meticulously, plaster casting is often the technique of choice due to its ability to capture these nuances. This method shines as well in medical applications, such as orthopedic casts, which rely on a perfect adaptability to complex body contours.

Other Articles You Might Enjoy

- 11 Different Types of Casting Process

Introduction to Casting Processes Casting stands as a cornerstone in the realm of manufacturing, enabling the creation of complex shapes and designs that would be challenging or impossible to achieve…

- The Impact of Material Selection on CNC Machining Costs and Lead Times

CNC Machining and The Essential Roles of Material Selection Computer Numerical Control (CNC) machining, a significant technology in the manufacturing industry, uses pre-programmed computer software to control machine tools. As…

- Mastering Bead Blasting in CNC Machining(types of casting Bennett)

Bead blasting is a critical method employed in the world of Computer Numerical Control (CNC) machining. With this mechanical process, smaller abrasive beads or particles are directed at high speed…