Introduction: CNC Machining and the Role of Titanium

In the realm of Computer Numerical Control (CNC) machining, each metal utilized possesses distinctive characteristics that cater to specific applications. An essential player in this diverse matrix is Titanium – a high-strength, lightweight metal known for its exceptional corrosion resistance. Often favored in industries such as aerospace and medical technology, it’s robustness and versatility make it an integral component within CNC machining processes. However, despite these valuable attributes, working with Titanium brings along its own set of challenges, including additional wear on tools due to its strength and the production of excessive heat during machining.

Roles of Titanium in CNC Machining

The performance of titanium makes it a prime choice for use within Computer Numerical Control (CNC) machining. The metal’s innate properties including its high strength-to-weight ratio and excellent resistance to corrosion, paves the way for creating robust machine components without sacrificing efficiency or weight balance. Its thermally conductive nature also aids in dissipating heat even while undergoing extreme speed operations.

An industry where titanium plays a crucial role is within aviation. No other materials match up to the requirements demanded by the aircraft industry as precisely as titanium does. Here are some reasons:

- Titanium carries fewer risks of thermal expansion issues which ensures less contractions and expansions during flight.

- It is highly resistant to corrosions which extends the components lifespan, saving costs in the long run.

- Titanium’s ability to withstand both low and high temperatures qualifies it to be used in various parts of an airplane, making it indispensable in intricate aerospace applications.

In summary, titanium stands out in the world of CNC machining due to its unique beneficial properties, thus contributing heavily in industries such as aviation, we see how pivotal this material truly becomes.

Advancements in Titanium Use in CNC Machining

The application of titanium in Computer Numerical Control (CNC) machining has seen significant enhancements over the years. One notable improvement is its increased durability, which results from high tensile strength and corrosion resistance features inherent in titanium. Compared to other metals used in CNC operations, titanium offers improved lifespan and effectiveness for parts exposed to harsh environments. Additionally, efficiency gains have also materialized due to advances in cooling technology that counteract the heat conductivity challenges associated with titanium. These improvements allow companies involved in aerospace, defense, medical, and automotive sectors to manufacture more robust and complex components capable of withstanding demanding usage.

- Increased durability: The high tensile strength and great corrosion resistance of titanium ensure a longer lifespan of machined parts.

- Enhanced efficiency: With modern cooling technologies, it’s possible to mitigate the challenge brought by titanium’s heat conductivity, leading to better operational efficacy.

The Advantages of Utilizing Titanium in CNC Machining

When it comes to CNC machining, titanium offers several advantages, including:

- Roughly 30% stronger and 50% lighter than steel

- Excellent resistance to high temperatures and corrosion

- Ideal for functional aircraft components and external parts

For professional CNC machining services, consider Precision Machining Service.

Challenges with Titanium in CNC Machining

In spite of its multiple advantages, the use of titanium in CNC machining also presents certain challenges which include cost and fabrication difficulty. Firstly, compared to other metals like aluminum or steel, titanium is considerably high-priced, hence increasing the production costs markedly. This steeper price can be attributed to its extraction and refinement process, which makes it less suited for projects constrained by budget limitations. Secondly, the complexity involved in machining titanium poses another significant issue.

- Titanium’s superior strength, while beneficial in many respects, simultaneously makes it more challenging to cut and shape.

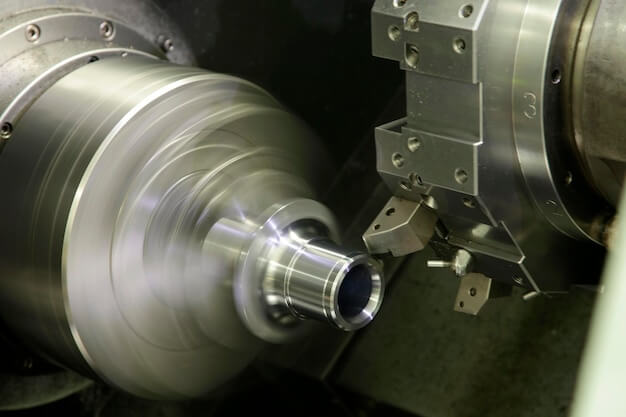

- The metal’s poor thermal conductivity leads to concentrated heat at the cutting edge during machining as heat does not dissipate easily. This could potentially damage both the machined component and the machine tooling, thus requiring special coolant techniques to prevent overheating problems.

- Furthermore, due to its reactive nature, titanium tends to adhere to the tool surface causing damages such as edge chipping and accelerated wear.

Overall, whilst titanium possesses impressive attributes that make it attractive for various industries, these aforementioned challenges must be thoroughly considered when using titanium in any CNC machining venture.

Balancing Benefits vs. Challenges of Titanium in CNC Machining

When considering the role of titanium in CNC machining, it’s vital to balance the benefits against the challenges. This decision-making process is often based on parameters like specific project requirements, budget constraints, and user needs. For instance, a key benefit of using titanium is its exceptional strength-to-weight ratio making it ideal for aerospace and automotive industries. However, these advantages may be offset by challenges such as the high cost of titanium material and the substantial wear and tear on the machinery due to titanium’s hardness.

- Project Requirements: If the project calls for extremely durable and lightweight parts, then despite the difficulties in processing, titanium becomes an obvious choice.

- Budget Constraints: Though cost-effective in the long-term due to its durability, titanium manufacture necessitates a higher initial investment.

- User Needs: Applications requiring long-lasting components with resistance to heat and corrosion would fare better with titanium, despite the associated tough cutting conditions.

Hence, deciding if the benefits of using titanium outweigh the challenges is primarily a matter of analyzing project specifics, keeping the financial aspects in view, and aligning these factors with end-user demands.

Future Innovations Expected with Titanium in CNC Machining

The continual development of manufacturing technologies is expected to bring about remarkable innovations associated with the use of titanium in CNC machining. One significant potential advancement lies in refining machine algorithms to enhance effectiveness and precision when working with this resilient metal, reducing material waste and decreasing energy consumption in the process.

- Additionally, breakthroughs in cutting tool design could further boost productivity levels by extending tool lifetimes and improving surface finishes.

- An emerging innovation also involves exploiting the excellent biomechanical compatibilities of titanium by introducing more complex and personalized forms, for applications such as medical implants and orthotic devices.

- In terms of environmental sustainability, we can anticipate enhancements in recycling technologies that maximize the reuse of titanium swarf produced during CNC machining – a step toward greener manufacturing practices.

While these projections may rapidly become realities given the current pace of industrial progression, they are not without their challenges. The complexities inherent in machining titanium — its high strength-to-weight ratio and low thermal conductivity — will require advanced technical knowledge and robust hardware capabilities. Nevertheless, the ceaseless push toward improved efficiency and performance drives ongoing efforts to innovate and optimize the role of titanium in CNC machining.

Conclusion

In conclusion, the role of titanium in CNC machining cannot be undermined due to its strong and light-weight properties, high corrosion resistance, excellent strength-to-density ratio, and more. However, it comes with certain challenges such as greater machining time because of its poor thermal conductivity, requirement for specialized cutting tools, and a need for slower feed rates. Proper tooling methods, cooling solutions, well-planned cutting tracks must be used to overcome these hurdles.

- Titanium’s strength and lightweight make it ideal for robust applications in industries such as aerospace and medical devices.

- The material’s high corrosion resistance characteristic increases its durability and longevity in any application.

- Due to Titanium’s low thermal conductivity, there is a necessity to incorporate efficient cooling mechanisms when dealing with higher machine speeds.

- To ensure optimized output, slowing down feeds and using specialized cutting tools is essential when working with titanium.

All in all, getting the most out of titanium in CNC machining requires expertise and precision alongside an understanding of both the benefits and complexities that come with this unique metal.

Other Articles You Might Enjoy

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…