When it comes to efficient removal and refining processes in the industry, Computer Numerical Control (CNC) machining stands tall among them. This technology harnesses modern computation power to allow for accurate, precise manipulation and modification of various materials such as lightweight metals. One particular application that might interest manufacturing businesses and hobbyists alike is removing chrome from metal surfaces.

Chrome finds extensive use in enhancing a metal’s aesthetic appeal and resistance to rust, tarnishing, and scratches. However, there are times when you’ll need, or want, to expose the underlying metal—either because the chrome has lost its lustre over time or due to reasons related to design changes and repurposing. The following sections would thus explore how you can leverage CNC machining techniques to remove chrome from lightweight metal parts safely and efficiently.

**Why Use CNC Machining to Remove Chrome?**

Given other approaches like grinding, sandblasting, chemical stripping, and heating, one may wonder why choose CNC machining? Firstly, these methods demand exhaustive caution and effort since mishaps could result in irreversible damage to the base material or create an unsafe environment. Secondly, they usually aren’t suitable where intricate features in your part require preserving during chrome removal—a challenge easily surmounted by accurate, controlled CNC operations.

Moreover, CNC machines offer versatility to work across a variety of lightweight metals—like aluminium, titanium, or magnesium alloys—that find wide-ranging applications nowadays due to their beneficial weight-to-strength ratios and specific characteristics. Consequently, setting up this automated process presents more value proposition than most alternatives.

**How Does a CNC Machine Remove Chrome?**

To understand how CNC machinery removes chrome from metal pieces, we must first look at some essential elements present in typical CNC systems:

1. **CAD Software**: Utilises CAD drawings of the component detailing areas requiring chrome removal.

2. **Controller Unit**: Consists of the computer interpreting CAD data and transforming it into control signals guiding machine operation.

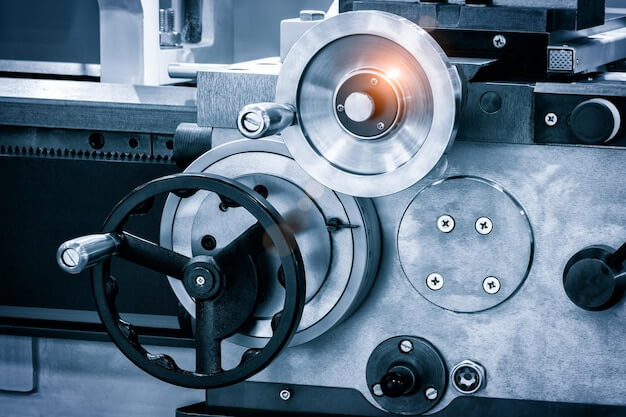

3. **CNC Machine**: Houses cutting or grinding tools that move according to directions received from the controller unit.

Starting with an encoded CAD drawing, CNC machines commonly employ high-speed, controlled abrasion using a series of fine grit wheels or brushes chosen explicitly for chrome removal. The material is then cooled during the procedure to prevent heat generation from affecting the part’s dimensional stability.

**Planning Your Chrome Removal Activity**

Before scheduling your CNC machining task, here are some recommendations:

1. Always ensure surface cleanliness before starting.

2. Choose appropriate tooling considering abrasive durability, impact strength, metal hardness, and other parameters.

3. Make sure you comply with environmental regulations concerning dust extraction and disposal since chromium falls under hazardous waste.

Just bear in mind—like other tasks involving refinishing of metals, you must approach this process methodically, patient enough to avoid causing damage to the base lightweight metal substrate underneath.

In conclusion, while there may be numerous methods available for removing chrome from metal surfaces, none can match the reliability, precision, and repeatability afforded by CNC technology when dealing with complex parts made of lightweight metals. This revered manufacturing technique not only helps preserve key features throughout the process but also provides a safe, easily manageable solution to enhance industrial productivity further. So the next time you need to deal with chrome-coated metal components, remember: CNC might just have the perfect answer!

Other Articles You Might Enjoy

- Titanium Grade 5 vs. Grade 23 in CNC Machining: Which is More Efficient?

Introduction: Titanium Grade 5 vs. Grade 23 in CNC Machining In the realm of Computer Numerical Control (CNC) machining, the use of titanium-based materials is quite prevalent due to their…

- Custom CNC Machining Solutions with Titanium for High Precision

Introduction to CNC Machining and Importance of Precision with Titanium CNC, Computer Numerical Control, machining is a sophisticated manufacturing process utilizing computers to control complex tools such as grinders, mills,…

- Efficient CNC Machining of Lightweight Metal and Chrome Removal( cnc machining services china Atwood)

Computer Numerical Control (CNC) machining is a modern manufacturing process used in various industries, frequently dealing with lightweight metals or needing to remove chrome from metal surfaces. This article will…