The Development and Technological Advantages of CNC Machining in China

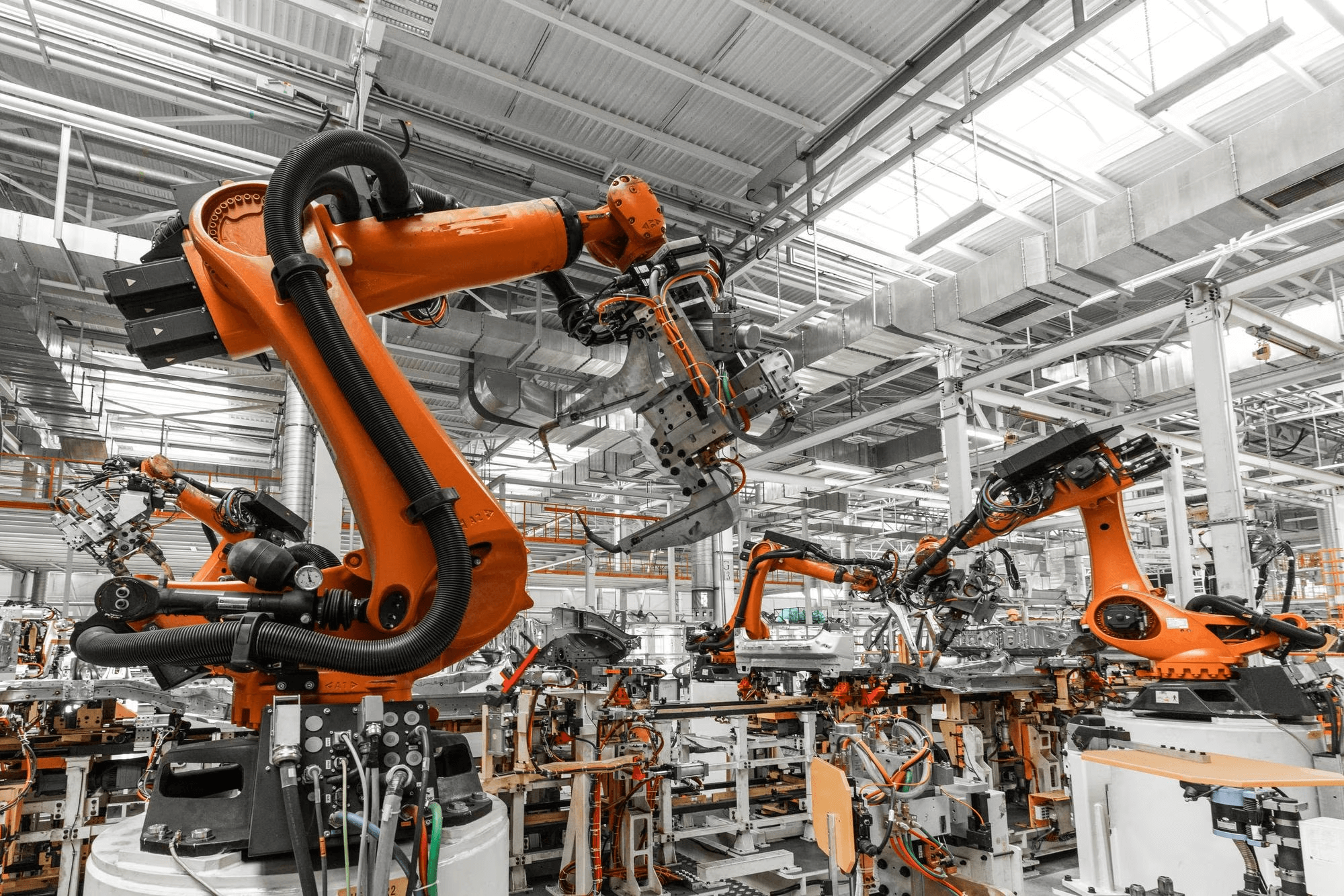

China’s rise as a global manufacturing powerhouse is inseparable from its advancements in CNC (Computer Numerical Control) machining technology. CNC machining has revolutionized manufacturing processes, allowing for high precision, efficiency, and automation. In China, the evolution of CNC technology has been marked by significant investment in research and development, leading to innovations that enhance the capabilities of robotic arms and other manufacturing equipment.In recent years, combined with the Internet, Chinese companies have also provided service for machining CNC parts online.

Porosity and Its Impact on Robotic Arms Manufacturing

Porosity, the presence of voids or air bubbles within materials, can significantly affect the manufacturing and performance of robotic arms. This issue is particularly relevant in processes like vacuum casting, which is often used in the production of components for robotic arms. Understanding and mitigating porosity is crucial for ensuring the durability, efficiency, and precision of these devices.

Understanding Porosity in the Context of Robotic Arms

Porosity can compromise the mechanical properties of materials used in robotic arms, leading to potential failures under stress and impacting the arm’s functionality. For robotic arms, which require high precision and durability, addressing porosity is essential.

Effects of Porosity:

- Weakened Material Strength: Compromises the robotic arm’s ability to perform tasks, especially those requiring high strength and durability.

- Surface Imperfections: Affects the aesthetic quality and may interfere with sensor functionality on the robotic arm.

- Functional Performance: Impacts the precision and reliability of the robotic arm, especially in applications requiring exact movements and operations.

Strategies for Mitigating Porosity in Robotic Arms Manufacturing

Mitigating porosity involves several strategies, from the design phase through to the final production stages. Here are some key approaches:

- Optimizing Mold Venting: Ensures air can escape efficiently during the casting process, reducing air entrapment.

- Adjusting Casting Resin Viscosity: Fine-tuning the viscosity to minimize the chances of air bubble formation.

- Implementing Rigorous Post-Casting Inspections: Identifies and addresses any porosity issues before the parts are assembled into the robotic arm.

Real-World Application: Ensuring Precision and Durability in Robotic Arms

In the manufacturing of robotic arms, addressing porosity is crucial for ensuring that the components meet the required specifications for precision and durability. For example:

- Aerospace Robotics: Robotic arms used in aerospace applications must withstand extreme conditions without failure. Optimizing mold venting and adjusting resin viscosity are critical steps in producing porosity-free components.

- Medical Robotics: For robotic arms used in medical procedures, surface imperfections resulting from porosity can compromise sterility and functionality. Rigorous post-casting inspections are essential to ensure the highest quality standards.

- Manufacturing Robotics: In industrial settings, the durability and reliability of robotic arms are paramount. Implementing strategies to mitigate porosity ensures that these devices can perform repetitive tasks with high precision over extended periods.

The Importance of CNC Machining Technology and Its Application in Robotic Arms

CNC machining plays a crucial role in the manufacturing of robotic arms, particularly in ensuring components are produced with the necessary precision and consistency. The precision of CNC machines enables the production of parts with tight tolerances, which is essential for the smooth and accurate operation of robotic arms. These machines can work with a variety of materials, from metals to plastics, allowing for a wide range of applications in industries such as automotive, electronics, and healthcare.

A prime example of CNC machining’s application in robotic arms is in the production of joint components, which require high precision for smooth articulation. The “RoboArm T-20,” a robotic arm used in precision assembly lines, utilizes joints manufactured using CNC machines capable of achieving tolerances within micrometers. This level of precision ensures that the RoboArm T-20 can perform intricate tasks, such as assembling small electronic components, with high accuracy and reliability.

Key Factors in Enhancing the Precision of Robotic Arms

Enhancing the precision of robotic arms involves several key factors, including the quality of materials used, the manufacturing processes, and the integration of advanced sensors and control systems. High-quality materials ensure durability and stability, while advanced manufacturing processes like CNC machining provide the necessary precision in component production.

Incorporating advanced sensors and control systems into robotic arms further enhances their precision. For example, the “PrecisionBot X2” employs state-of-the-art sensors that provide real-time feedback on the arm’s position and movement, allowing for adjustments to be made instantaneously to maintain accuracy. This integration of technology results in a robotic arm capable of performing tasks with exceptional precision, critical in applications such as surgical robotics, where even the slightest deviation can have significant consequences.

The Role of China’s CNC Technology in Improving the Operational Precision of Robotic Arms

China’s advancements in CNC technology have played a significant role in improving the operational precision of robotic arms. The continuous improvement in CNC machining processes and equipment has enabled the production of components with higher precision, contributing to the overall performance and reliability of robotic arms.

An illustrative case is the collaboration between a Chinese CNC machine manufacturer and a robotics company to produce the “MegaPrecise” robotic arm, which is used in high-precision manufacturing environments. The MegaPrecise arm features components produced with advanced CNC machines that ensure a level of precision previously unattainable, enabling the arm to perform tasks with micron-level accuracy.

Case Study: Success Stories of Robotic Arms Made in China

One success story is the “AssembleMaster-3000,” a robotic arm developed by a Chinese robotics firm for the automotive industry. The AssembleMaster-3000 is renowned for its ability to assemble intricate components with high precision and speed, significantly improving production efficiency and reducing error rates. This success can be attributed to the use of high-precision gears and joints manufactured through CNC machining, ensuring smooth and accurate operation.

Another example is the “PaintPro X,” a robotic arm used in the automotive painting process. The PaintPro X stands out for its ability to apply paint with uniform thickness and precision, a result of components manufactured with CNC technology that ensure smooth and controlled movement.

Future Prospects: Development Trends and Opportunities for CNC Machining Technology in China

The future of CNC machining technology in China is promising, with trends pointing towards further automation, integration with artificial intelligence (AI), and the use of more sustainable materials. These advancements are expected to drive the development of even more precise and efficient robotic arms, opening up new possibilities in various industries.

One area of development is the integration of AI with CNC machines, allowing for more adaptive and intelligent machining processes. This integration could lead to the creation of robotic arms that can learn and improve their performance over time, adapting to different tasks and materials with minimal human intervention.

In conclusion, China’s expertise in CNC machining is playing a pivotal role in elevating the precision of robotic arms, driving advancements in manufacturing and opening up new possibilities across various industries. The continuous innovation in this field is not only enhancing the capabilities of robotic arms but also contributing to the broader goal of achieving higher efficiency, precision, and reliability in manufacturing processes worldwide.

Other Articles You Might Enjoy

- Precision Prowess: Unveiling the Advantages of China CNC Machining

1. Introduction: The Role of Precision in Manufacturing Excellence In this introductory section, we delve into the critical role that precision plays in manufacturing and set the stage for an…

- Revolutionizing CNC Machining for Complex Aerospace Assemblies

Introduction to CNC Machining in Aerospace Assemblies Computer Numerical Control (CNC) machining represents a significant technological development playing a notable role in the creation of complex aerospace assemblies. CNC machining…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…