Introduction

Elongation is one of those material properties that doesn’t always get the attention it deserves—until something breaks. I’ve seen it firsthand in my work with CNC machining projects: a part passes dimensional inspection but fails under load. Why? Low elongation. That was the first time I realized how much elongation can affect the real-world performance of machined components.

This guide is for engineers, machinists, product designers, and anyone else who makes decisions about material selection and part geometry. If you’ve ever wondered what “elongation at break” means in a data sheet, or why some metals behave better under stress, this article will clear it up.

We’ll cover the basics of elongation, how it affects machining, what values to watch for, and how it fits into quality control. We’ll even dig into data tables comparing elongation across dozens of common alloys. By the end, you’ll understand how to design and machine parts with ductility in mind—and how to avoid costly mistakes.

The Role of Elongation in Machining

Elongation might not be the first thing engineers consider when machining a part, but it has a bigger impact than most realize. Whether you’re working on aluminum brackets, stainless fittings, or aerospace-grade titanium components, understanding elongation gives you a serious edge in both design and production.

I learned this the hard way when machining some 7075-T6 aluminum parts for a structural application. The dimensions were spot on, surface finish looked great, but the parts were failing under minor flex. We eventually traced it back to the material’s low elongation—around 6%. The metal was strong, but not ductile enough for the loads it faced.

2.1 What Does Elongation Actually Do in Machining?

Elongation measures how much a material can stretch before it breaks. In machining, this translates into how the material responds to cutting forces. Ductile materials (with higher elongation) are more forgiving. They deform slightly under tool pressure rather than chipping or cracking.

Brittle materials with low elongation can:

- Fracture during aggressive toolpaths

- Leave poor surface finishes

- Develop microcracks that lead to part failure

2.2 Brittle vs. Ductile Behavior Under Cutting

Let’s compare how two metals behave when machined:

| Property | 6061 Aluminum (Ductile) | Gray Cast Iron (Brittle) |

|---|---|---|

| Elongation (%) | ~12–18% | <1% |

| Chip Type | Continuous | Powdery/broken |

| Surface Finish | Smooth | Rough, tool wear risk |

| Tool Load Response | Slight deflection | Risk of cracking |

| Post-processing Risk | Low | High |

I’ve machined both, and I can tell you: with cast iron, even slight tool wear or wrong feeds can cause chunking and edge fracture. Aluminum, with higher elongation, flexes slightly and absorbs some tool pressure.

2.3 High Elongation Helps With:

- Better chip control

- Less risk of edge chipping

- Higher feed rates possible

- More tolerance to minor tooling defects

- Improved surface finish

2.4 But… It’s Not All Upside

High elongation also means:

- More tool wear from material buildup on edges

- More burrs (especially in softer alloys)

- Risk of material deformation if not clamped tightly

2.5 Real-World Examples

| Material | Elongation (%) | Machining Behavior |

|---|---|---|

| 7075-T6 | 6–9% | Strong but unforgiving under stress |

| 304 Stainless | 40–60% | Ductile, gummy, needs sharp tools and coolant |

| Brass C360 | 25–30% | Excellent machinability and ductility |

| Zamak 3 | 7–10% | Clean cutting but brittle in thin sections |

In one medical project I worked on, we switched from 316 stainless to a titanium alloy with lower elongation. The surface quality improved, but the failure rate in flex tests rose by 20%. Elongation mattered more than we expected.

2.6 Final Thoughts on Elongation’s Role in Machining

Elongation doesn’t just affect how a part behaves under load—it affects how it behaves while you’re machining it. If your parts are cracking, chipping, or showing stress marks during cutting, it’s worth checking the material’s elongationand rethinking your process or material selection.

Elongation vs Machinability: Finding the Balance

When choosing a material, we often think in binary: either it’s easy to machine, or it’s strong. But the truth is more nuanced. One of the trickiest trade-offs in manufacturing is between elongation and machinability. In many cases, the more ductile a material is (meaning it has higher elongation), the more challenging it becomes to machine efficiently.

I’ve seen this repeatedly, especially when switching between alloys like 304 stainless steel (high elongation, low machinability) and free-machining brass (moderate elongation, excellent machinability). This section will help you understand where the sweet spot lies—and how to find the right balance for your application.

3.1 Why Ductility (Elongation) and Machinability Often Compete

Machinability depends on how easily a material can be cut. High elongation often means the material resists fracture and flows more during machining—which leads to problems like:

- Gummy chips that wrap around tools

- Increased tool wear from built-up edge (BUE)

- More burr formation on exit edges

- Overheating, requiring heavy coolant use

Meanwhile, materials with low elongation (i.e., more brittle) tend to:

- Break off chips cleanly

- Leave crisp edges

- Allow higher speeds and feeds

- Risk edge cracking under stress

3.2 Example: 304 Stainless vs C360 Brass

| Property | 304 Stainless | C360 Brass |

|---|---|---|

| Elongation (%) | 40–60% | 25–30% |

| Machinability Rating (1–100) | ~40 | ~100 |

| Chip Control | Poor (stringy) | Excellent |

| Tool Wear | High | Very Low |

| Surface Finish | Requires polishing | Very smooth as-cut |

| Application Note | High strength/ductility | Best for high-volume machining |

I’ve had tool life drop 60% when switching from brass to stainless without adjusting RPM and feed rates. Same machine, same cutter—very different results, all because of elongation and material flow.

3.3 When You Want High Elongation

Choose materials with higher elongation when:

- The part must deform under load (crash zones, brackets)

- You’re machining thin-walled or flexible structures

- The part undergoes cold working or forming

- You’re aiming for ductile failure rather than brittle

3.4 When You Want High Machinability (Even with Lower Elongation)

Opt for lower-elongation materials when:

- You need to reduce cycle time

- Surface finish is critical and post-processing is limited

- You’re machining hundreds or thousands of parts

- You need tight dimensional accuracy without tool deflection

3.5 Comparative Table: Elongation vs Machinability Across Common Alloys

| Material | Elongation (%) | Machinability (1–100) | Notes |

|---|---|---|---|

| 6061-T6 Aluminum | 8–12 | 60–70 | Balanced; good all-purpose alloy |

| 7075-T6 Aluminum | 6–9 | 45–55 | High strength, lower ductility |

| Brass C360 | 25–30 | 100 | Top machinability, fair elongation |

| 304 Stainless | 40–60 | 35–45 | High ductility, hard to machine |

| A36 Steel | 20–23 | 60 | Structural; decent compromise |

| Titanium Grade 5 | 10–14 | 25–35 | Strong, poor heat dissipation |

| Zamak 3 (Zinc) | 7–10 | 75–85 | Clean machining, limited ductility |

3.6 My Rule of Thumb

If a material’s elongation is above 20% and its machinability rating is below 50, expect:

- Shorter tool life

- The need for coolant

- More time spent deburring

- Potential dimensional drift in thin parts

When we do short-run prototypes, we often tolerate poor machinability for better elongation. But in high-volume production, machinability wins, and we reinforce the part design to make up for reduced ductility.

3.7 Key Takeaways

- Elongation and machinability are usually in tension

- You can’t optimize for both without compromise

- Design, tolerance, and volume all affect the right balance

- Use data tables to compare and justify material choices

In the next section, I’ll cover how elongation affects part design, especially in high-stress or precision-critical applications.

Design Considerations Related to Elongation

When I first started reviewing failed parts from the field, I mostly focused on geometry and stress. But as I got deeper into the analysis, I realized how much of a part’s performance is tied to elongation. It’s not just a material property on a datasheet—it determines how a part deforms, fails, or survives under stress.

This chapter dives into the practical ways elongation influences design, especially for machined components. If you’re designing anything that needs to endure mechanical loading, thermal stress, or even minor impacts, elongationshould be part of your design logic.

4.1 Why Elongation Matters in Design

Elongation tells us how much plastic deformation a material can undergo before breaking. From a design perspective, this affects:

- Stress distribution in load-bearing areas

- Crack resistance in sharp corners or holes

- Fit tolerances for press-fit or interference parts

- Flexibility of thin walls or curved surfaces

If you ignore elongation and use a brittle material where ductility is needed, your part might pass simulation but fail in the real world—especially under repeated or uneven loads.

4.2 Key Design Features Affected by Elongation

| Feature Type | Elongation Design Impact |

|---|---|

| Thin walls | Low elongation materials may crack during machining |

| Threads | High elongation resists stripping or cracking under torque |

| Internal corners | High-elongation materials tolerate tighter corner radii |

| Snap fits or clips | Require high elongation to flex without breaking |

| Mounting holes | May deform during tightening if elongation is too high |

| Cantilevered arms | Need ductility to absorb flex without fracturing |

I once worked with a design that had tight internal corners in a titanium part. On paper, everything looked good—but in reality, the toolpath stress led to microcracks due to limited elongation. Adding a 1.5 mm fillet and switching to Grade 2 titanium (more ductile) solved the issue.

4.3 CAD and Simulation Considerations

Many designers overlook elongation because their CAD tools default to “linear elastic” stress models. But in reality:

- Materials don’t just stretch—they yield and flow.

- Elongation influences necking, stress redistribution, and failure paths.

- If you simulate with a yield point only, you miss ductile failure behavior.

For parts under vibration, impact, or fatigue, simulate using nonlinear material models that include elongation and strain hardening.

4.4 Designing for Ductile Failure (vs. Brittle)

In many industries, ductile failure is preferred. Why?

- It gives warning (visible deformation before failure)

- It absorbs energy (important in crash zones)

- It’s more forgiving of manufacturing variation

| Failure Mode | Description | Elongation Influence |

|---|---|---|

| Ductile Failure | Stretching/necking before rupture | Requires high elongation (>15%) |

| Brittle Failure | Sudden fracture without warning | Occurs in low-elongation materials |

| Fatigue Fracture | Crack growth from cyclic stress | Mitigated by ductility & elongation |

If your application involves repeated loading, elongation plays a key role in slowing crack growth—which often determines the true lifespan of a part.

4.5 Common Elongation Ranges for Design Scenarios

Here’s a quick guide based on what I’ve seen work well in real-world designs:

| Application Type | Recommended Elongation (%) | Material Suggestions |

|---|---|---|

| Structural load bearing | 12–25% | Low-carbon steel, 6061-O aluminum |

| Press-fit parts | 15–30% | Brass, ductile aluminum |

| Thin walls or shells | >20% | 304 SS, Grade 2 Ti, copper |

| Flexing under tension | >25% | Pure copper, soft stainless |

| Tight tolerances only | <10% (more stable) | 7075-T6, Zamak 3 |

4.6 My Design Checklist When Considering Elongation

Before locking down a design, I ask myself:

- Does the part flex, press-fit, or bend in use?

- Will machining leave stress risers or sharp corners?

- Will this material yield or snap under worst-case loading?

- Can I justify a more ductile material if strength is over-designed?

I’ve saved clients from costly redesigns just by recommending a different alloy with better elongation—sometimes it’s a small material change that solves a big production problem.

4.7 Summary

- Elongation influences every part of the design lifecycle, from modeling to post-processing

- Don’t rely on simulation alone—match elongation to real-world usage

- Prioritize ductility in designs with stress concentration, vibration, or unknown loads

- Small changes (like adding radii or switching tempers) can drastically improve results

How Machining Affects Elongation

Most of us look at a material’s elongation from a datasheet and assume it stays constant throughout the manufacturing process. But in reality, machining can change a material’s elongation—sometimes in subtle ways, sometimes drastically.

I’ve seen parts pass mechanical requirements as raw stock, only to become brittle after milling or drilling. That shift is almost always due to microstructural changes introduced by machining. If you’re aiming for high ductility or depend on elongation to absorb stress, you need to understand how your machining process could be working against you.

5.1 Is Elongation Affected by Machining?

Yes, in several ways. While you’re removing material, you’re also introducing:

- Residual stresses

- Surface hardening (work hardening)

- Heat-affected zones (especially in grinding or dry cutting)

These effects alter the material’s ability to stretch, bend, and yield.

5.2 Residual Stress and Its Influence on Elongation

When you cut metal, the distribution of internal stress changes. The more aggressive your cut (e.g., large depth, high RPM), the more stress you may introduce.

This stress can:

- Make the material less ductile in localized zones

- Lead to unexpected failure near machined features

- Interfere with post-processing like welding or forming

I once oversaw a batch of aluminum plates that were warping after heat treatment. The root cause? Uneven residual stresses from an aggressive face milling process, which altered how the parts reacted under heat—and reduced elongation in critical regions.

5.3 Work Hardening (Strain Hardening)

Some metals—especially stainless steels, copper alloys, and titanium—are prone to work hardening. This happens when the surface layer undergoes plastic deformation during cutting, making it harder and more brittle.

Consequences of work hardening:

- Decreased elongation near surface

- Cracks during secondary operations (like forming or tapping)

- Inconsistent mechanical behavior across the part

| Metal | Work Hardening Tendency | Effect on Elongation |

|---|---|---|

| 304 Stainless Steel | High | Surface becomes brittle |

| Titanium Grade 5 | Medium | Heat buildup reduces ductility |

| 6061 Aluminum | Low | Generally stable |

| Copper C110 | High | Needs sharp tools, low feeds |

5.4 Heat-Affected Zones (HAZ)

Although HAZ is more often discussed in welding, it’s also relevant in high-speed machining, dry cutting, and grinding. Excess heat changes grain structure, which affects elongation.

Materials like:

- Titanium

- Hardened steels

- Magnesium alloys

are particularly sensitive.

In one project involving precision medical parts in Ti-6Al-4V, we found that improper cooling during slotting reduced surface elongation by nearly 30%—enough to cause breakage during pressure testing.

5.5 Common Machining Factors That Affect Elongation

| Machining Factor | Risk to Elongation | Prevention Tip |

|---|---|---|

| High RPM, low feed | Generates heat, HAZ | Use coolant, adjust feed |

| Dull tools | Work hardens surface | Replace or regrind regularly |

| Deep cuts | Induce internal stress | Use multiple shallow passes |

| Interrupted cuts | Shock loads, micro-cracks | Pre-drill or soften entry |

| Dry cutting | Heat + chip welding | Apply coolant or minimum quantity lube |

| Grinding | High thermal effect | Use slow speeds and coolants |

5.6 Elongation-Sensitive Operations

These processes are more likely to reduce elongation if not controlled properly:

- Threading (especially tapping)

- Reaming and boring

- Slotting (sharp internal corners concentrate stress)

- Grinding and surface finishing

If elongation is critical to your application, evaluate these operations closely. You may need to redesign tooling paths or introduce post-machining stress relief.

5.7 How to Preserve Elongation During Machining

- Use sharp tools to reduce cutting forces

- Optimize cutting parameters (balanced RPM/feed)

- Apply proper coolant to limit thermal damage

- Avoid excessive deformation during fixturing

- Use stress-relief heat treatments post-machining if needed

5.8 Summary

- Yes, machining can and often does reduce elongation, especially near the surface

- Residual stress, heat, and work hardening are the main causes

- Smart process control helps preserve ductility in critical zones

- Always re-evaluate material specs after machining, especially for parts under tension or bending

Testing and Measuring Elongation

Understanding elongation is one thing—measuring it accurately is another. Whether you’re qualifying incoming materials, testing prototypes, or verifying final part quality, measuring elongation helps ensure your parts behave as expected under load. Over the years, I’ve worked with labs, QA teams, and machinists who needed to validate ductility for critical components. Here’s what I’ve learned about getting elongation measurements right.

6.1 What Does Elongation Measurement Actually Mean?

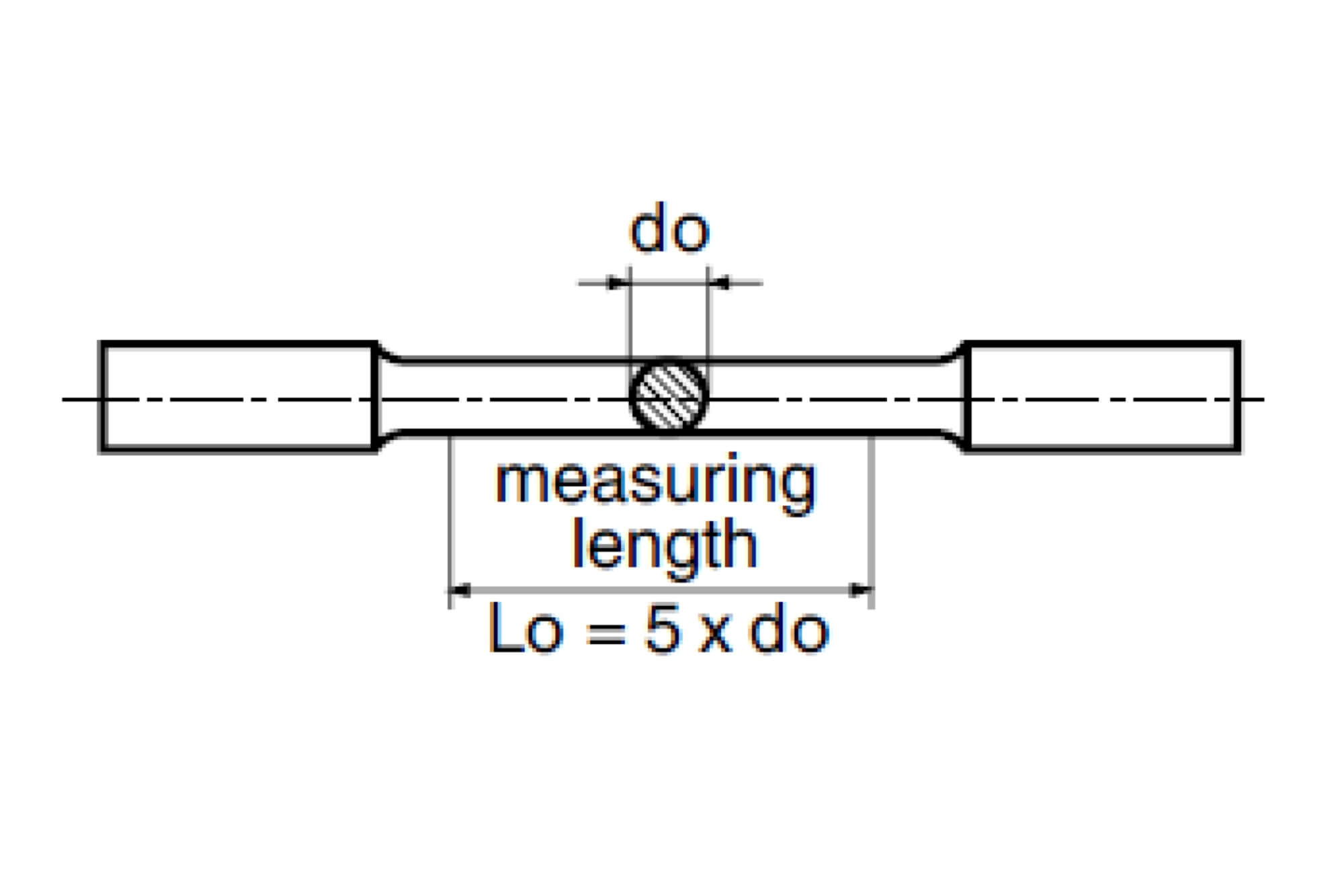

Elongation is typically expressed as a percentage of increase in length from the original size of a specimen before it breaks under tensile stress.

Elongation (%) = [(Final gauge length – Initial gauge length) ÷ Initial gauge length] × 100

This number helps us understand how ductile the material is. It’s typically measured as:

- Elongation at break (total deformation before failure)

- Elongation at yield (start of plastic deformation)

For most engineering purposes—especially in machining—we care most about elongation at break.

6.2 Standard Testing Methods

There are two main global standards for tensile and elongation testing:

| Standard | Region | Test Specimens | Key Features |

|---|---|---|---|

| ASTM E8/E8M | USA | Round/flat | Widely used in metals testing |

| ISO 6892-1 | International | Round/flat | Common in Europe/Asia |

Both require:

- Controlled strain rates

- Precisely machined test specimens

- Measurement across a standard gauge length (typically 25–50 mm)

6.3 Equipment Used to Measure Elongation

| Tool/Device | Function | Accuracy |

|---|---|---|

| Universal Testing Machine (UTM) | Applies tensile load, captures elongation | High |

| Extensometer | Tracks change in gauge length | Very high |

| Digital calipers | Basic before-and-after measurement | Medium |

| Video extensometers | Non-contact, high-precision imaging | Very high |

In most of my projects, we relied on servo-hydraulic or screw-driven UTM systems. For high-elongation materials like 304 stainless, we always paired it with clip-on extensometers to track early necking.

6.4 Preparing Test Specimens

Accuracy starts with good sample prep:

- Use machined specimens to match ASTM or ISO dimensions

- Remove all surface burrs or tool marks

- Avoid introducing stress during cutting

- Store and test at room temperature for consistency

I once got widely different elongation readings from two batches of 6061-T6 aluminum, only to realize one batch was waterjet cut (causing edge hardening), while the other was CNC-milled. Lesson: test prep affects results.

6.5 Sample Test Results Table

Here’s a sample table showing real-world elongation data from tensile testing:

| Material | Sample ID | Gauge Length (mm) | Elongation at Break (%) | Notes |

|---|---|---|---|---|

| 6061-T6 Aluminum | A1 | 50 | 9.2 | Within expected range |

| 304 Stainless | B3 | 50 | 51.0 | High ductility |

| 7075-T6 Aluminum | A7 | 25 | 6.8 | Confirmed low elongation |

| Brass C360 | C2 | 25 | 29.1 | Great for press fits |

| Ti-6Al-4V | T5 | 50 | 13.4 | Acceptable for application |

6.6 Interpreting Elongation Test Results

Here’s what the values mean:

- <5% = Very brittle

- 5–15% = Low ductility, high strength

- 15–30% = Balanced ductility, machinability

- 30–60% = High ductility (e.g., annealed steels, soft metals)

Also look for:

- Necking behavior: Is deformation uniform or concentrated?

- Failure mode: Clean break vs tearing vs grain-boundary fracture

- Repeatability: Multiple samples should show <5% variation

6.7 Tips for Reliable Elongation Testing

- Test multiple samples to avoid anomalies

- Maintain controlled strain rate per standard

- Use proper clamping—no slippage

- Record both elongation and reduction of area for more insights

- Test after machining, not just on raw stock, when possible

6.8 Summary

- Accurate elongation measurement is essential for quality control and material validation

- Use proper standards (ASTM E8, ISO 6892) and prepare specimens carefully

- Machining methods can affect test results—always consider test timing and sample history

- Elongation values aren’t just numbers—they reflect how a part will behave under real stress

Elongation in Quality Control and Manufacturing

When I walk into a CNC or metal fabrication shop, the conversations about quality usually center on tolerances, surface finish, and hardness. But when you’re producing parts that must perform under stress, elongation becomes just as critical. It plays a major role in verifying material quality, evaluating mechanical performance, and ensuring compliance with specs in high-stakes industries like aerospace, automotive, and medical devices.

This chapter explains how elongation fits into the bigger picture of quality control and why it’s a metric you should never ignore.

7.1 Why Is Elongation Important in QC?

Elongation is one of the clearest indicators of a material’s ability to absorb energy without failing. It shows how ductile a part is after all machining and heat treatment are completed.

Here’s how QC teams use elongation:

- To verify raw material batches meet specification

- To check if machining or processing altered material behavior

- To qualify parts that require certified ductility (e.g., implants, brackets)

- To reject brittle parts that don’t meet elongation minimums

7.2 Common Industry Standards Involving Elongation

| Industry | Standard / Code | Elongation Requirement Example |

|---|---|---|

| Aerospace | AMS / MIL specs | 10–14% for titanium, >20% for 2024 Al |

| Automotive | SAE / ISO standards | >20% for crash-safety components |

| Medical Device | ASTM F136 / ISO 5832 | >10% for implant-grade titanium |

| Oil & Gas | NACE MR0175 | >15% for sour service metals |

Many of our clients in aerospace require test reports with elongation data per lot before accepting material. If the elongation is 1–2% lower than spec, the batch is rejected—no exceptions.

7.3 Batch Testing and Statistical Acceptance

Not every part gets tested. That’s where sampling and statistical controls come in. Most shops use AQL (Acceptable Quality Limit) or Lot Acceptance Testing (LAT) strategies.

For elongation, the approach is usually:

- Test 3–5 samples per batch

- Use ASTM E8 or ISO 6892 as the basis

- Accept/reject the batch based on elongation minimum

Example: If a batch of 304 stainless steel has a minimum spec of 45% elongation and two out of five samples fall below that, the whole lot may be flagged.

7.4 When to Perform Elongation Tests

| Test Timing | Purpose |

|---|---|

| Pre-machining | Validate raw material from vendor |

| Post-machining | Check for heat/work hardening impact |

| After surface finish | Ensure treatments (e.g., anodizing) didn’t degrade ductility |

| Final QA inspection | Certify part performance under load |

I’ve personally seen elongation drop 10–15% after hard anodizing aluminum parts, which could be a deal-breaker in a flexible application. That’s why we recommend elongation tests after the final process, not just at the raw bar stage.

7.5 Common Elongation Pitfalls in Manufacturing

| Pitfall | Risk | Prevention Strategy |

|---|---|---|

| Using uncertified stock | Unknown ductility, inconsistent parts | Require MTCs (Material Test Certs) |

| Not testing post-machining | Hidden brittleness from stress | Run occasional post-process tensile tests |

| Using incorrect test method | Misleading results | Follow proper gauge length, strain rate |

| Ignoring surface treatments | Elongation reduction | Re-test after anodizing or coating |

| Overlooking edge conditions | Premature failure in use | Chamfer or deburr stress risers |

7.6 Integrating Elongation into ISO & AS9100 Workflows

For manufacturers certified under ISO 9001 or AS9100, elongation data can be part of:

- First Article Inspection Reports (FAIRs)

- Process FMEAs (Failure Mode & Effects Analysis)

- Supplier Qualification Documentation

- Production Part Approval Process (PPAP) for automotive

One client we worked with in aerospace had elongation thresholds programmed into their ERP system. If a batch of 6061-T6 aluminum came in with 7% elongation instead of 10%, the PO was auto-rejected before it hit the floor.

7.7 Should Machinists Care About Elongation?

Yes—and here’s why:

- Machining affects elongation

- Some operations (like threading or forming) demand ductile zones

- Knowing your material’s elongation helps you avoid waste, tool wear, and rework

Even if you’re not a materials engineer, knowing that 304 stainless is more forgiving than 7075 aluminum can help you make better tool and strategy choices.

7.8 Summary

- Elongation is a critical quality metric, especially in regulated industries

- Testing should occur at multiple stages: before, during, and after processing

- Use proper sampling, measurement, and certification to stay compliant

- QC teams, machinists, and engineers all benefit from understanding elongation trends

In the next section, we’ll look at real-world use cases across industries, showing how elongation affects performance in everything from aircraft to surgical tools.

Real Industry Applications

There’s a big difference between understanding elongation in theory and seeing how it plays out in real-world manufacturing. In this section, I’ll share examples of how elongation influences design, machining, and quality control across different industries. I’ve worked on projects in several of these sectors, and it’s clear: when elongation is ignored, parts fail—sometimes catastrophically.

8.1 Aerospace: Ductility for Fatigue and Crash Resistance

In aerospace, elongation is a critical design factor because parts often experience repeated stress cycles, vibration, and thermal shifts. Engineers favor materials that won’t fail suddenly under stress—ductile failure is preferred over brittle breakage.

Common elongation ranges:

- 2024-T3 aluminum: ~18%

- 7050-T7451: ~11%

- Titanium Grade 5 (Ti-6Al-4V): ~13–14%

Example: We machined rib structures for a UAV wing using 2024-T3. The high elongation meant the parts could absorb airframe vibration and minor impact without cracking. Lower elongation options were cheaper—but the testing showed they’d fail under fatigue loads.

8.2 Automotive: Controlled Deformation in Crash Zones

Elongation is directly linked to energy absorption during a crash. Many structural parts, including crumple zones and seat supports, use high-elongation materials to deform gradually, slowing impact forces.

| Component | Preferred Elongation (%) | Common Material |

|---|---|---|

| Bumper mounts | 15–25% | Low-carbon steel |

| Seat brackets | 18–22% | 6061-T4 aluminum |

| Crumple zones | 25–30% | Drawn steel or high-ductility aluminum |

| Suspension arms | 12–18% | Forged aluminum |

I once reviewed a failure analysis on a seat bracket that cracked at the bolt hole after a minor accident. Turns out the supplier had switched from 6061-T4 to 7075-T6 without realizing the elongation dropped from ~16% to 7%. That mistake triggered a recall.

8.3 Medical Devices: Ductility for Safety and Fit

Medical components like surgical tools, bone plates, and implants require not just strength, but controlled flexibility. Elongation affects everything from insertion force to breakage risk.

| Medical Part | Typical Elongation Requirement | Notes |

|---|---|---|

| Bone plates | ≥ 10% | Absorb motion without failure |

| Orthopedic screws | ≥ 8–12% | Withstand insertion torque |

| Surgical scissors | 15–20% | Avoid snapping under use |

| Stents (not machined) | 30–60% (Nitinol) | Superelastic, high ductility |

A client had a run of titanium bone plates that were fracturing in post-op. Lab tests showed the elongation was just 7%, below the 10% requirement. The cause? Over-machining and no post-machining stress relief.

8.4 Oil & Gas: Ductility in High-Pressure, High-Corrosion Environments

In oil and gas, materials are subjected to extreme pressure and chemical attack. Elongation matters not just for strength, but for toughness and crack resistance in sour service.

Standards like NACE MR0175 require a minimum elongation of 15–20% in corrosion-resistant alloys.

| Component | Target Elongation (%) | Material Example |

|---|---|---|

| Valve stems | ≥ 15% | Duplex stainless |

| Pressure fittings | ≥ 18% | Inconel 625 |

| Downhole connectors | ≥ 20% | Alloy 718 (heat treated) |

We had to requalify an Inconel part because the original batch came in with only 12% elongation—fine for strength, but not compliant for sour gas applications.

8.5 Electronics and Consumer Products: Managing Thin Walls

In less-critical applications, elongation helps manage thin-walled machining, snap fits, and press-fit assemblies. While strength often dominates marketing specs, ductility improves manufacturability.

- Zinc alloys like Zamak 3 (elongation 7–10%) are ideal for die casting but can crack if too thin

- 6061-O or 5052 aluminum (~20% elongation) offers a good balance for CNC’d enclosures

- Brass C360 (~25%) allows snap fits without splitting

I once helped redesign a handheld scanner case. The original spec used 7075 aluminum for rigidity, but it cracked at mounting holes. We switched to 6061-O, lost some stiffness—but zero failures since.

8.6 Summary of Elongation Use Cases by Industry

| Industry | Key Function of Elongation | Consequences if Overlooked |

|---|---|---|

| Aerospace | Fatigue resistance, impact absorption | Cracking under vibration |

| Automotive | Crash energy management | Structural failure in collisions |

| Medical | Flexibility, break resistance | Fracture during implantation |

| Oil & Gas | Crack resistance under pressure/corrosion | Brittle failure in harsh conditions |

| Electronics | Thin-wall flexibility, snap fit durability | Part breakage during assembly |

8.7 Takeaway

- Elongation isn’t just a material spec—it’s a performance enabler

- Every industry uses it differently, but the goal is the same: safe, reliable deformation under stress

- Choosing the right elongation range for your application can prevent costly redesigns, failures, and even recalls

Reference Elongation Data of Common Metals and Alloys

When it comes to selecting materials for machining, elongation is a critical mechanical property that often separates success from failure—especially in high-stress, fatigue-prone, or flexible applications. But not all metals are created equal, and more importantly, not all versions of a metal offer the same ductility.

In this chapter, I’ve compiled practical, engineering-grade reference tables for the most commonly used metals in machining, organized by material family. These tables include:

- Typical elongation at break values (%)

- Machinability ratings (qualitative)

- Suggested use cases based on performance and behavior

This isn’t just textbook data—these are the elongation ranges I’ve seen or used in real projects, backed by experience and field-tested understanding.

9.1 Aluminum Alloys

Aluminum alloys offer a wide range of elongation values depending on temper and composition. Annealed grades like 6061-O are very ductile, while heat-treated grades like 7075-T6 offer higher strength at the cost of elongation.

| Alloy | Temper | Elongation (%) | Machinability | Use Case |

|---|---|---|---|---|

| 6061 | O | 18–22% | Good | Thin-wall parts, formed brackets |

| 6061 | T6 | 8–10% | Very Good | General CNC parts, jigs, fixtures |

| 7075 | T6 | 6–9% | Moderate | Aerospace structures, arms, spindles |

| 2024 | T3 | 10–15% | Moderate | Aircraft skins, fatigue-critical parts |

| 5052 | H32 | 12–16% | Good | Sheet metal panels, marine enclosures |

9.2 Carbon and Alloy Steels

Carbon steels like A36 offer good elongation for structural use. Alloy steels such as 4140 provide higher strength with moderate ductility.

| Steel Grade | Type | Elongation (%) | Machinability | Use Case |

|---|---|---|---|---|

| A36 | Mild Carbon | 20–23% | Good | Structural beams, welded assemblies |

| 1018 | Cold-rolled | 15–20% | Good | Shafts, bushings, gears |

| 4140 | Heat-treated | 14–18% | Moderate | Tooling, spindles, load-bearing parts |

| 4340 | Alloy Steel | 10–14% | Fair | Aircraft landing gear, drive shafts |

9.3 Stainless Steels

Stainless steels, especially austenitic types like 304 and 316, have excellent elongation but are notoriously difficult to machine.

| Grade | Type | Elongation (%) | Machinability | Use Case |

|---|---|---|---|---|

| 304 | Austenitic | 40–60% | Poor | Food equipment, medical housings |

| 316 | Austenitic | 50–60% | Poor | Marine, pharmaceutical parts |

| 17-4PH | Annealed | 16–20% | Moderate | Aerospace, tooling, pump components |

| 17-4PH | H900 | 10–12% | Moderate | High-strength stainless assemblies |

| 15-5PH | H1025 | 12–14% | Moderate | Precision hardware, fasteners |

9.4 Copper and Brass

These metals are very ductile and excellent for forming or press-fit assemblies, though copper can be challenging to machine.

| Alloy | Type | Elongation (%) | Machinability | Use Case |

|---|---|---|---|---|

| C110 | Pure Copper | 45–50% | Poor | Conductive busbars, connectors |

| C360 | Free-machining brass | 25–30% | Excellent | Valves, bushings, high-volume turned parts |

| C464 | Naval Brass | 30–40% | Good | Marine components, corrosion-resistant pins |

9.5 Titanium Alloys

Titanium offers high strength-to-weight ratios. Commercially pure titanium (Grade 2) is more ductile than high-strength Grade 5 (Ti-6Al-4V).

| Grade | Description | Elongation (%) | Machinability | Use Case |

|---|---|---|---|---|

| Grade 2 | Commercially Pure | 20–25% | Moderate | Medical implants, corrosion-resistant parts |

| Grade 5 | Ti-6Al-4V | 10–14% | Challenging | Aerospace fasteners, surgical components |

9.6 Zinc and Zinc Alloys

Zinc alloys like Zamak 3 are widely used in die casting but offer relatively low elongation. Suitable for non-structural parts.

| Alloy | Type | Elongation (%) | Machinability | Use Case |

|---|---|---|---|---|

| Zamak 3 | Die-cast zinc | 7–10% | Very Good | Enclosures, electronics housings |

9.7 Magnesium Alloys

Magnesium is the lightest structural metal. Elongation varies greatly by alloy. AZ31 is more ductile than AZ91.

| Alloy | Type | Elongation (%) | Machinability | Use Case |

|---|---|---|---|---|

| AZ31B | Wrought | 10–18% | Good | Aerospace brackets, light structural parts |

| AZ91D | Die-cast | 2–5% | Fair | Electronic casings, consumer products |

9.8 Nickel-Based Alloys (High Temp Alloys)

Superalloys are built for heat and corrosion resistance, but their elongation and machinability are often secondary to strength.

| Alloy | Type | Elongation (%) | Machinability | Use Case |

|---|---|---|---|---|

| Inconel 625 | Nickel Superalloy | 30–50% | Difficult | Exhaust systems, marine components |

| Hastelloy C276 | Corrosion Alloy | 40–50% | Difficult | Acid environments, chemical plant equipment |

9.9 Cast Irons

Cast iron is extremely brittle despite being easy to machine. Use with caution when elongation or impact resistance matters.

| Type | Description | Elongation (%) | Machinability | Use Case |

|---|---|---|---|---|

| Gray Cast Iron | Standard | 1–2% | Excellent | Machine bases, engine blocks |

| Ductile Iron | Spheroidal Graphite | 8–12% | Good | Structural castings, pipes |

9.10 Key Takeaways

- Always check elongation for the specific alloy and temper, not just the base metal

- Use high-elongation metals for dynamic loads, fatigue, and forming

- Use low-elongation materials only in static, overbuilt, or non-stress-critical zones

- Machinability and elongation don’t always align—you’ll often have to compromise

In the final content chapter, we’ll bring everything together with summary insights and design recommendations to help you apply elongation data intelligently across real projects.

Summary and Engineering Recommendations

Over the years, I’ve worked with teams across aerospace, automotive, consumer electronics, and medical manufacturing—and one pattern I’ve noticed is this: when elongation is considered early in the design process, part performance and machining success almost always improve.

This final chapter wraps up everything we’ve covered so far and delivers practical, action-ready recommendationsfor engineers, designers, and manufacturers working with metals in machining environments.

10.1 Recap: Why Elongation Matters

Elongation reflects how much a material can stretch before breaking, and it’s tightly tied to real-world properties like:

- Ductility

- Fracture resistance

- Energy absorption

- Formability

- Fatigue life

It directly affects how a part performs under:

- Stress or vibration

- Insertion and assembly forces

- Impact or crash conditions

- Temperature fluctuations

And yet, many CAD models are designed only for strength and stiffness, ignoring ductility—until something fails in the field.

10.2 Elongation’s Role in the Full Product Lifecycle

| Stage | Elongation Consideration |

|---|---|

| Material selection | Choose elongation range suited to your part’s application |

| Machining | Adjust feeds, speeds, and tooling for ductile or brittle behavior |

| Stress analysis | Prefer ductile failure (necking, deformation) over brittle |

| Assembly & fitment | Ensure parts can flex slightly without cracking |

| Post-processing | Monitor how heat or coating changes ductility |

| QC and testing | Measure elongation in final parts to verify compliance |

10.3 Common Engineering Mistakes to Avoid

I’ve personally seen each of these lead to costly errors:

- Assuming all aluminum alloys are ductile

→ 7075-T6 is strong but has poor elongation; don’t use for flexing parts. - Skipping post-machining ductility testing

→ Work hardening or residual stress may reduce effective elongation by 20–30%. - Using low-elongation alloys in fatigue-critical parts

→ This is how cracks propagate fast, especially around bolt holes and threads. - Choosing high-elongation materials for tight tolerance parts

→ May deform slightly under clamping, leading to out-of-spec measurements.

10.4 Engineering Recommendations Checklist

Before you cut a single chip or approve a new drawing, run through this:

✅ Have I chosen a material with appropriate elongation for the part’s use?

✅ Does the machining process preserve the ductility needed in critical zones?

✅ Are threads, thin walls, and corners designed to avoid stress risers?

✅ Is the supplier-certified elongation documented on the MTC?

✅ Do our QC tests include elongation measurement where necessary?

✅ Am I using a nonlinear simulation model if elongation is crucial?

✅ Do I have a contingency plan if a lower-elongation substitute material is used?

10.5 Example Use Case: Bracket Under Load

Let’s say you’re designing a bracket that holds a 50kg load and is mounted with two bolts. It will experience vibration and occasional shock. You’re considering 7075-T6 because of its strength—but you should ask:

- Will it crack near bolt holes over time due to low elongation?

- Should you switch to 2024-T3 or 6061-O for better ductility?

- Can you machine small radii into corners and reduce sharp edges?

I’ve helped teams make this exact call. When the bracket broke in drop testing, switching to a higher-elongation alloy fixed the problem—without needing to redesign the part.

10.6 Best Practices by Application Type

| Application | Recommended Elongation Range | Material Guidance |

|---|---|---|

| Crash/flex zones | ≥20% | 5052, A36, 304 SS |

| Fatigue-sensitive parts | ≥15% | 2024-T3, Ti Grade 2 |

| High-precision parts | 6–12% | 7075-T6, 17-4PH |

| Threads & fasteners | 10–25% | Brass, stainless, mild steel |

| Press-fit or inserts | ≥25% | Copper, C360 brass |

10.7 Final Thoughts

If there’s one takeaway from this entire guide, it’s this:

Elongation is not just a number—it’s a window into how your part will behave in the real world.

Designers need to stop thinking of materials as “strong” or “easy to machine” and start thinking in terms of how a material deforms, stretches, and ultimately fails.

You don’t need to become a materials scientist—but by checking elongation early and often, you can avoid failures, improve quality, and build parts that actually perform as intended.

FAQ

1. What is elongation in materials science?

Elongation refers to the amount a material can stretch or extend under tension before breaking, usually expressed as a percentage of the original length.

2. Why is elongation important in CNC machining?

Elongation affects how a part will deform during use—and even during machining. High elongation materials resist cracking, tolerate vibration, and are more forgiving during tool engagement.

3. How is elongation measured?

It’s measured using a tensile test machine, following standards like ASTM E8 or ISO 6892. A specimen is pulled until it breaks, and the percentage increase in gauge length is recorded.

4. What’s the difference between elongation and ductility?

Ductility is a material property, while elongation is a way to quantify it. Materials with high elongation are considered ductile; those with low elongation are brittle.

5. What is considered a “high” elongation?

Generally, any value above 20% is considered high elongation and indicates good ductility. Values below 10% are considered brittle.

6. Does machining reduce elongation?

Yes, it can. Machining introduces residual stresses and sometimes surface work hardening, which may reduce local elongation, especially near corners and thin walls.

7. Which metals have the highest elongation?

Metals like annealed 304 stainless steel, pure copper (C110), and aluminum 6061-O can reach elongation levels of 40–60%.

8. Which common alloys have low elongation?

7075-T6 aluminum, Zamak 3 zinc alloy, and gray cast iron typically have elongation values under 10%, making them prone to brittle failure.

9. What’s the typical elongation of 6061 aluminum?

It ranges from 18–22% in the O (annealed) condition to 8–10% in the T6 (heat-treated) condition.

10. Can anodizing or coating reduce elongation?

Yes. Surface treatments like anodizing, especially hard coat anodizing, can reduce ductility by creating a brittle surface layer.

11. How does elongation affect fatigue life?

Higher elongation helps slow crack propagation and improves resistance to fatigue failure, especially in cyclic loading applications.

12. Is elongation more important than tensile strength?

Depends on the application. For crash zones, fatigue, or forming, elongation matters more. For static loads or precision parts, tensile strength may be prioritized.

13. Can elongation be increased after machining?

Sometimes. Stress-relief heat treatments or annealing can restore some ductility lost during machining—but not always fully.

14. How do I choose the right elongation value for my part?

Base it on:

- Functional load conditions

- Risk of impact, vibration, or flexing

- Desired failure mode (ductile vs brittle)

A general rule: the more unpredictable the loading, the higher elongation you’ll want.

15. Can I test elongation in-house?

Yes, if you have access to a tensile testing machine and proper fixturing. Otherwise, send samples to a certified materials lab with ASTM/ISO capabilities.

16. How does elongation relate to press-fit or snap-fit design?

High elongation materials like copper or brass can deform slightly to allow fit without cracking, making them ideal for press-fit parts.

17. Does elongation affect dimensional stability?

Not directly—but more ductile materials may deflect slightly under clamping or machining forces, which affects tight tolerances.

18. How can I balance elongation and machinability?

Use the material data table (see Chapter 9). If you need both, compromise with alloys like 6061-O or C360 brass, which offer decent machinability and moderate elongation.

19. Should I ask for elongation on my material test certificate (MTC)?

Absolutely. Especially if ductility is critical to your design. MTCs often include elongation—request it if it’s missing.

20. What happens if a part with low elongation is used in a high-vibration application?

It may crack, snap, or fail suddenly under stress. Low elongation materials are not ideal for fatigue-prone or shock-loaded designs.

Authoritative References on Elongation and Tensile Testing

- ASTM E8/E8M – Standard Test Methods for Tension Testing of Metallic Materials

This standard outlines the procedures for determining the tensile properties of metallic materials, including elongation. It specifies specimen preparation, testing methods, and calculations.

🔗 ASTM E8/E8M-22 Standard - ISO 6892-1:2019 – Metallic Materials — Tensile Testing — Part 1: Method of Test at Room Temperature

An international standard that specifies the method for tensile testing of metallic materials at room temperature, detailing how to determine mechanical properties such as yield strength and elongation.

🔗 ISO 6892-1:2019 Standard - Cambridge Materials Data – Elongation Property Information

Provides an overview of elongation as a material property, its significance in manufacturing, and how it’s measured through tensile testing.

🔗 Cambridge Materials Data on Elongation - Britannica – Elongation in Physics

Offers a general explanation of elongation within the context of physics and materials science, discussing how materials deform under tensile stress.

🔗 Britannica: Elongation - ADMET – Measuring the Ductility of Metals

This white paper discusses methods for measuring ductility, including elongation and reduction of area, and explains their relevance in material testing.

🔗 ADMET White Paper on Ductility - ScienceDirect – Influence of Milling Induced Residual Stress on Fatigue Life

Examines how residual stresses from machining processes like milling can affect the fatigue life of materials such as Aluminum 7075, highlighting the importance of considering elongation in design.

🔗 ScienceDirect Article

Other Articles You Might Enjoy

- How Ductility Influences CNC Machining Processes

Introduction Ductility is a critical material property that significantly influences the CNC machining processes used in manufacturing. It refers to a material's ability to deform under tensile stress, which allows…

- Decoding Carbon Fiber Strain in Advanced Machining Applications

Introduction: The Unique Properties and Applications of Carbon Fiber I’ve always been fascinated by how materials behave under stress. Carbon fiber, in particular, has this almost legendary status in aerospace,…

- Why Shear Strain Matters in CNC Machining

The Importance of Shear Strain in CNC Machining Understanding shear strain is essential not only for selecting the right materials but also for optimizing machining processes in CNC applications.but also…

- Understanding the Stress Strain Curve for CNC Material Selection

The Importance of the Stress-Strain Curve in CNC Machining In the world of CNC machining, understanding the stress-strain curve isn't just a technical necessity—it's a strategic advantage. When I first…

- The Ultimate Guide to Stress Relieving for CNC Parts: When, Why, and How

Introduction Stress relieving has always been a point of fascination for me. I remember the first time I discovered how much of a difference it makes in CNC machined parts.…

- Yield Strength vs Tensile Strength: CNC Material Choice and Process Optimization

I. Introduction 1. Definition of Yield Strength and Tensile Strength I remember the first time I encountered the terms yield strength and tensile strength in my early machining projects. Yield strength refers to the…

- The Role of the Shear Stress Equation in CNC Process Optimization

A Personal Approach to CNC Process Optimization As someone who’s spent years working in the CNC machining field, I've come to realize that understanding the Shear Stress Equation is not…

- How Does Tensile Stress Affect CNC Machining Processes

Tensile stress is a fundamental concept in material science that has far-reaching implications in CNC machining processes. Understanding how tensile stress interacts with various materials can greatly impact the effectiveness…