Introduction to the Concept of CNC Machining in Custom Designs

In an era where customization is king, CNC (Computer Numerical Control) machining has emerged as a vital tool for creating bespoke items. This technology allows digital files to be transformed into physical objects via a computer-controlled manufacturing process. It works by directing machines like drills and lathes with precise commands to shape raw material according to defined specifications.

- The technology boasts high accuracy: its detailed programming eliminates human error possibility by automating complex tasks that would traditionally require manual labour.

- CNC machining brings design dreams to life: it enables impressive versatility since virtually any material can be manipulated, from metal to plastic, opening up endless possibilities for custom designs.

- Last but not least, using CNC for custom designs enhances efficiency: Being computer-guided equates to faster production times and less waste, making this methodology both cost-effective and environmentally friendly.

In essence, CNC machining plays a significant role in enabling creators to realize their unique visions, albeit digitally crafted jewellery or distinct furniture pieces.

The Evolution of Manufacturing Technologies

The evolution of manufacturing technologies signifies a shift from conventional production methods to more advanced digital fabrication systems. Traditionally, manufacturing dealt largely with manual labor where artisans painstakingly handcrafted each product down to the finest details. Techniques varied widely – ranging from forging, casting and milling to shaping, grinding, and drilling. However, these techniques were often time-consuming, required high-level skill sets, and lacked consistency in results.

In contrast, the advent of automated and digital fabrication solutions heralded a new age in manufacturing technology. One key development was Computer Numerical Control (CNC) machining which introduced automation into traditionally manual processes. This form of manufacturing automates tools through computer programming. Now, manufacturers could produce parts with enhanced precision, speed, and consistency without the labour-intensive processes previously required. Therefore, CNC represents a defining step in the transition away from traditional methods towards more efficient, automated production processes:

- Precision: Enables exact replication of designs with extremely close tolerances.

- Efficiency: Reduces production time by performing multiple operations simultaneously.

- Variety: Accommodates a diverse range of materials and complex geometries.

Understanding Computer Numerical Control (CNC) Machining:

- CNC machining is a subtractive manufacturing process that uses computerized machine tools to create custom-designed parts.

- The process involves programming and operating computer-controlled machine tools like mills, lathes, and routers to produce parts by removing material.

- This article provides a comprehensive guide to understanding the intricacies of computer numerical control (CNC) machining.

From Imagination to Implementation: The CNC Machining Process

The transformation of a design concept into a tangible product through the use of CNC machining is a meticulously orchestrated process that hinges on the synergy between software, machines, and operators. For instance, imagine creating a custom car part using this technology. Initially, the idea is birthed in the mind of a designer then translated into a digital sketch via Computer-Aided Design (CAD) software. This CAD file serves as the blueprint for the CNC machine.

- Software: Directly responsible for translating the initial creative vision into a digitized plan that the machines can interpret. Its role ensures precision, consistency, and fine details are accurately represented in the finished product.

- Machines: Brought into action once the design plans have been streamlined by the software. These mechanized systems, guided by preset coordinates from the software, seamlessly execute raw material cutting, drilling, or shaping jobs with remarkable accuracy and speed.

- Operators: Play an indispensable role in overseeing the entire production process. Besides feeding materials into the CNC machine, they monitor its operation, make necessary adjustments, conduct quality checks, and undertake maintenance activities regularly to preserve operational efficiency.

CNC machining, therefore, involves a step-by-step approach – from imagination to implementation – marked by distinctive yet collaborative roles performed supremely by the software, machinery, and operators working harmoniously towards achieving the end goal of a bespoke design realization.

The Role and Benefits of CNC Machining in Custom Design Production

CNC (Computer Numerical Control) machining has revolutionized the production process for custom designs, playing a pivotal role in facilitating unique, tailor-made products. Unlike traditional manufacturing techniques that are often inefficient and unable to cater specifically to intricate design needs, CNC machining offers an array of benefits that contribute significantly to its popularity within various industries.

Firstly, it provides high-precision production supported by computer-programmed commands which diminishes the risk of human error. Secondly, this technology is highly flexible; virtually any custom design can be produced using CNC machines regardless of the complexity or uniqueness of the prototype. Thirdly, CNC machining fosters streamlined mass reproduction: once a design blueprint has been incorporated into the software, identical units can be produced en masse with uncompromised quality.

Last but not least, cost-effectiveness is another significant advantage. Although implementation costs might seem daunting initially, the long-term economic efficiency offered by reduced labor-intensive processes and wastage largely outweighs these costs. For example, automotive companies commonly use CNC machining to achieve accurate, fast, and efficient fabrication when producing individually customized car parts. This inherently testifies to the impact and potential CNC holds particularly in the realm of crafting tailor-made designs.

Potential Challenges and Solutions in Implementing CNC Machining

Turning an imaginative concept into a tangible product using Computer Numerical Control (CNC) machining involves facing several potential challenges. One common barrier is the misconception that CNC machines are complicated and difficult to operate, especially for beginners. This can largely be attributed to the technological intricacies associated with 3D blueprints and programming precision cuts. However, modern CNC machines come with user-friendly software interfaces which help simplify these tasks.

The following points provide guided tips on overcoming such barriers:

- Educate: Acquire basic knowledge about how the machine works. Understand its components – like the cutting tool which shapes material, and the control panel that controls manufacturing processes.

- Training: Attend training sessions or opt for online tutorials to understand usage of the software.

- Simplify Designs: Initial designs should be simple to decrease the chance of errors during production.

- Seek Assistance: When needed, do not hesitate to seek advice from experienced users or even the machine manufacturers.

Another challenge often faced is that CNC machines might seem expensive at first. However, it’s important to consider the return on investment over time, as they perform complex productions quickly, accurately, and consistently thus saving time and resources long-term.

Real-Life Applications of CNC Machining in Different Industries

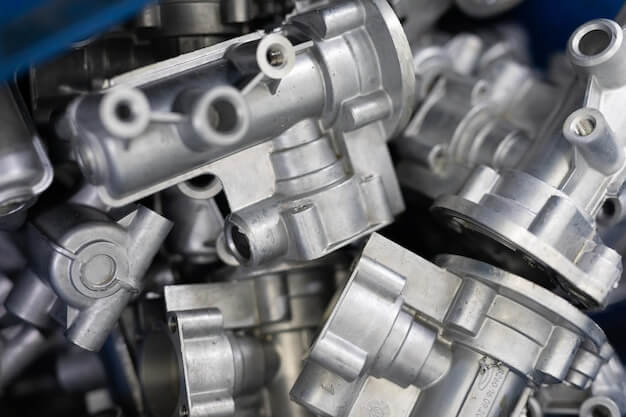

CNC machining has found vast applications across different industries, showcasing its versatility and efficiency. The car manufacturing hub or the automobile industry extensively relies on CNC machining for creating intricate parts with high precision. Similarly, CNC machining proves critical within the aerospace sector – an arena where accuracy is non-negotiable.

- In automobiles, everything from engine parts to shafts, gears, and even custom spare parts can be effectively crafted using this technology. For instance, Tesla-incorporated Rohm’s automation solutions optimize their high-speed CNC machining processes to achieve better production levels.

- The Aerospace industry requires an added layer of security measures due to the crucial nature of components. Here, Leistritz Turbinentechnik uses 5-axis CNC machining to manufacture complex turbine airfoil sections ensuring minimal deviation.

This underlines how CNC machining facilitates a streamlined execution of complex custom designs across different sectors, enhancing both productivity and accuracy.

Conclusion

In conclusion, CNC Machining has demonstrated its essential role in custom designs through various instances. This technology offers an array of benefits from increased accuracy and efficiency to flexibility in design implementation. Consideration was given on intricate aspects such as robotic automation, adaptive machining, and high-speed machining techniques. Each component plays a unique part; for instance, adaptive machining enables adjustments according to real-time conditions while high speed is crucial for efficient production.

The revolution within the field of CNC machinery does not stop here. As we gaze ahead into the future advancements, it’s exciting to envisage how further improvements might increasingly integrate artificial intelligence or even quantum computing to exert more complex tasks with unprecedented precision. The possibilities are limitless and only bound by our creativity and technical innovation.

Related Posts

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Innovative CNC Machining for Advanced Sporting Goods

Innovative CNC Machining for Advanced Sporting Goods CNC machining, or Computer Numerical Control machining, is a high-precision manufacturing process where pre-programmed computer software dictates the movement of factory machinery and…

- Custom CNC Machining Solutions for Brass and Stainless Steel

Introduction to Custom CNC Machining Solutions for Brass and Stainless Steel Custom CNC (Computer Numerical Control) machining is a manufacturing process that involves programmed codes directing the movement of factory…