The robotics industry is rapidly evolving, driven by advancements in technology and increasing demand for automation across various sectors. CNC machining plays a crucial role in enhancing the development and efficiency of robotics. This article explores the future of the robotics industry, how CNC machining boosts its growth, and the synergies between robotics and CNC.

1. The Future of the Robotics Industry

The robotics industry is poised for significant growth and transformation in the coming years. Several trends and factors are shaping its future:

- Advancements in AI and Machine Learning: The integration of artificial intelligence (AI) and machine learning enables robots to perform more complex tasks, learn from experiences, and adapt to new environments. This will lead to smarter and more versatile robots.

- Increased Automation: As industries seek to improve efficiency and reduce costs, the demand for automation is rising. Robots are increasingly being deployed in manufacturing, logistics, healthcare, and other sectors to automate repetitive and hazardous tasks.

- Collaborative Robots (Cobots): Cobots, designed to work alongside humans, are becoming more prevalent. They enhance productivity by combining human dexterity and decision-making with robotic precision and strength.

- Miniaturization and Precision: There is a growing trend towards smaller, more precise robots capable of performing delicate tasks in fields such as electronics manufacturing and medical surgery.

- Sustainability and Energy Efficiency: The development of eco-friendly robots with reduced energy consumption is gaining traction, aligning with global sustainability goals.

2. How CNC Machining Enhances the Robotics Industry

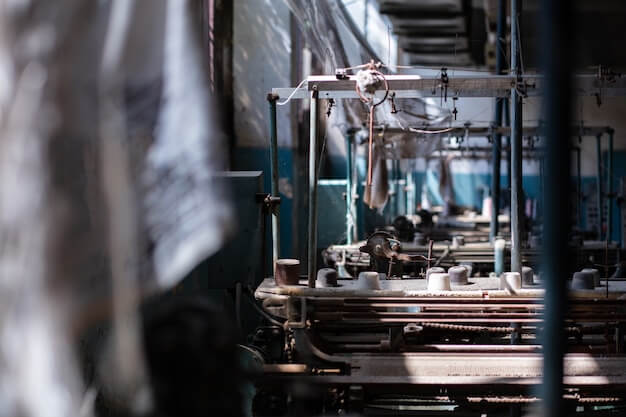

CNC machining is a vital technology that significantly contributes to the advancement of the robotics industry in several ways:

- Precision and Accuracy: CNC machining provides high precision and accuracy, essential for manufacturing intricate robot components. This ensures that robots perform reliably and efficiently.

- Customization and Flexibility: CNC machines can be programmed to produce custom parts tailored to specific robotic applications. This flexibility allows for rapid prototyping and adaptation to evolving technological requirements.

- Scalability: CNC machining supports both small-scale and large-scale production, making it suitable for producing unique robot components and mass-manufacturing standard parts.

- Material Versatility: CNC machines can process a wide range of materials, including metals, plastics, and composites. This versatility is crucial for creating durable and lightweight robot parts.

- Cost Efficiency: CNC machining reduces material waste and labor costs, enhancing the overall cost efficiency of robot production.

3. Synergies Between Robotics and CNC

The integration of robotics and CNC machining creates a powerful synergy that drives innovation and efficiency in both industries:

- Automated CNC Machining: Robots are increasingly used to automate CNC machining processes. Robotic arms can load and unload materials, change tools, and perform quality inspections, reducing human intervention and increasing productivity.

- Enhanced Manufacturing Precision: The combination of robotic precision and CNC machining accuracy results in higher quality components. Robots can handle delicate parts with consistency, minimizing errors and defects.

- Improved Workflow Efficiency: Robots can work alongside CNC machines to streamline workflows. They can manage repetitive tasks, allowing human operators to focus on more complex and value-added activities.

- Innovative Applications: The synergy between robotics and CNC machining leads to innovative applications, such as the production of custom robotic end-effectors and the development of advanced robotic systems for CNC operations.

- Smart Manufacturing: Integrating robotics with CNC machining supports the concept of smart manufacturing. Real-time data collection and analysis enable predictive maintenance, process optimization, and enhanced decision-making.

In conclusion, the future of the robotics industry is bright, with significant advancements driven by AI, automation, and sustainability. CNC machining plays a crucial role in supporting this growth by providing precision, flexibility, and cost efficiency. The synergy between robotics and CNC enhances manufacturing processes, driving innovation and productivity in both fields. As these technologies continue to evolve, their combined impact will shape the future of manufacturing and automation.

Related Posts

- Unlocking New Possibilities in CNC Machined Titanium Medical Devices

Introduction to CNC Machined Titanium Medical Devices The prevalence of CNC machined titanium medical devices in the healthcare sector demonstrates their immense significance and usefulness. This technology furnishes an essential…

- CNC Aluminum Machining Services: Advanced Techniques for Perfect Parts

CNC Aluminum Machining Services In the current manufacturing landscape, CNC aluminum machining services play a pivotal role. CNC which simply translates to 'Computer Numerical Control', is an advanced technique used…

- Hastelloy vs. Stainless Steel in Chemical Processing Equipment: CNC Machining Perspectives?

Hastelloy vs. Stainless Steel in Chemical Processing Equipment: An Introduction In the realm of chemical processing equipment, two commonly used materials include Hastelloy and stainless steel. Hastelloy, a reputed superalloy…