Introduction

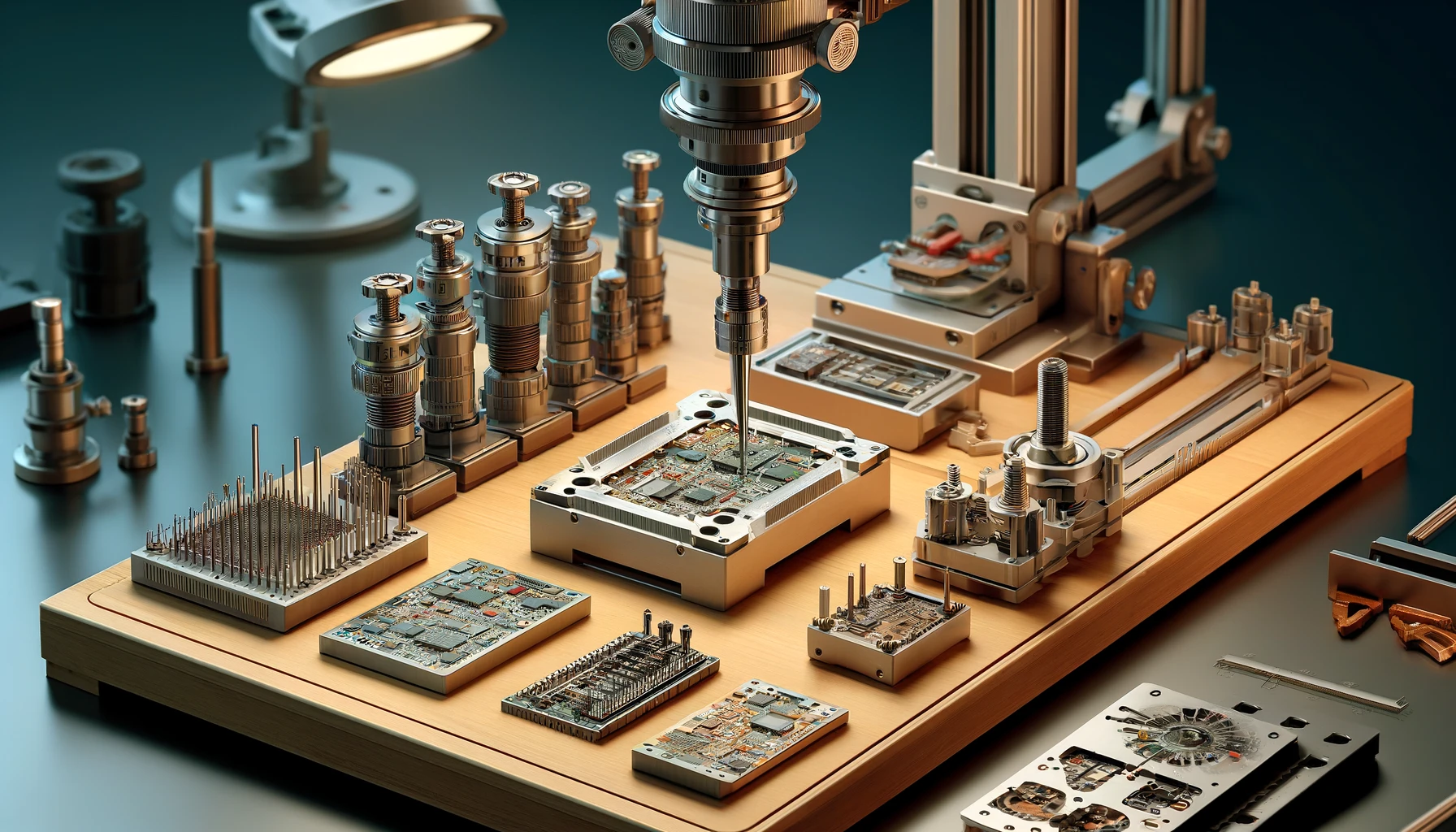

In the dynamic world of electronics manufacturing, the precision of PCB fixtures not only dictates the efficiency of the manufacturing process but also the functionality and reliability of the final electronic products. China, as a global hub for CNC machining, has been at the forefront of adopting and innovating custom CNC machining practices to meet the ever-evolving demands of precision in PCB fixture manufacturing. This article aims to shed light on the multifaceted challenges of achieving unparalleled precision in custom CNC machining for complex PCB fixtures and explores the state-of-the-art solutions that are setting new benchmarks in the industry.

Now, you can try to submit processing requirements such as “PCB Fixtures” through the Internet and get online cnc machining quote.

Understanding the Precision Requirements for PCB Fixtures

PCB fixtures serve as the backbone for holding and securing PCBs during various stages of manufacturing and testing, necessitating absolute precision to ensure the accurate alignment of components. These fixtures must conform to stringent precision standards to facilitate the seamless integration of PCBs into electronic devices. Delving deeper into the precision requirements, it becomes evident that even the most minute deviations can compromise the electrical connectivity and functionality of the final products, making precision not just a requirement but a critical necessity for PCB fixtures.

Common Precision Challenges in Custom CNC Machining

The path to achieving high precision in custom CNC machining is fraught with challenges, from dealing with the inherent material variances to compensating for the subtle yet impactful machine tool wear. Each challenge demands a unique solution, tailored to the nuances of the specific machining process and the desired outcome. A compelling case study from the automotive industry, where the margin for error is virtually non-existent, reflects the parallels with the precision challenges faced in machining PCB fixtures. The stringent requirements for component precision in the automotive sector offer valuable insights into the methodologies and strategies that can be effectively applied to CNC machining for PCB fixtures.

Material Selection and Its Impact on Machining Precision

The strategic selection of materials stands at the forefront of precision machining challenges, especially when it comes to fabricating components as delicate and crucial as PCB fixtures. The material not only dictates the ease of machining but also significantly influences the final product’s precision, durability, and performance under operational conditions. This section delves into the intricate relationship between material properties and CNC machining outcomes, providing a comprehensive overview of how material choice impacts the precision of CNC-machined PCB fixtures.

Materials for CNC machining are chosen based on a multitude of factors, each contributing to the machining process’s complexity and precision. Factors such as machinability, strength, thermal stability, and cost efficiency play pivotal roles in material selection. For instance, materials with high machinability ratings, such as certain aluminum alloys and brass, are often preferred for their ease of cutting, which allows for higher precision and smoother finishes. Conversely, materials like stainless steel and titanium, known for their strength and durability, pose significant machining challenges, requiring specialized tools and slower machining speeds to achieve the desired precision.

Data Table: Properties of Common Materials Used in CNC Machining

| Material | Machinability Score | Thermal Conductivity | Coefficient of Thermal Expansion | Strength-to-Weight Ratio |

|---|---|---|---|---|

| Aluminum 6061 | 90% | 167 W/mK | 23.6 µm/m-K | High |

| Brass C36000 | 100% | 120 W/mK | 20.5 µm/m-K | Moderate |

| Stainless Steel 304 | 45% | 16.2 W/mK | 17.2 µm/m-K | High |

| Titanium Grade 5 | 20% | 6.7 W/mK | 8.6 µm/m-K | Very High |

| Acrylic | Non-metal | 0.2 W/mK | 70 µm/m-K | Low |

| Polycarbonate | Non-metal | 0.2 W/mK | 65 µm/m-K | Moderate |

The table above provides a snapshot of the diverse properties of materials commonly utilized in CNC machining. Each material presents a unique set of challenges and advantages in the machining process. For example, Aluminum 6061, with its high machinability score and excellent thermal conductivity, is a favored choice for intricate PCB fixtures that require high levels of precision. Its ability to dissipate heat efficiently minimizes thermal expansion during machining, thereby enhancing precision.

Conversely, materials with lower machinability scores, such as Titanium Grade 5, demand more from the machining process. Despite its challenges, titanium’s exceptional strength-to-weight ratio and resistance to corrosion make it an invaluable material for applications where durability and precision are paramount. Machining such materials necessitates advanced CNC techniques and specialized tooling to maintain the desired levels of precision.

Moreover, the choice of material is not solely dictated by its machinability or physical properties. Economic considerations, availability, and the intended application of the PCB fixture also play critical roles in material selection. For instance, while brass offers excellent machinability and is cost-effective, it might not be suitable for all applications due to its moderate strength and weight ratio.

In summary, the selection of materials for CNC machining PCB fixtures is a complex decision-making process that requires a deep understanding of material properties, machining capabilities, and the specific requirements of the PCB fixture. The right material choice lays the foundation for achieving the high precision necessary in today’s advanced electronic devices.

Advanced CNC Machining Techniques for Enhanced Precision

In the quest for ultra-precise PCB fixtures, the advent of advanced CNC machining techniques has been a game-changer. These sophisticated methods not only elevate the precision achievable but also redefine the boundaries of what’s possible in CNC machining. This section explores several cutting-edge techniques that have been instrumental in overcoming traditional precision limitations, providing a detailed look into how they are applied to the fabrication of complex PCB fixtures.

One of the most transformative techniques in this arena is 5-axis CNC machining. Unlike traditional 3-axis systems, 5-axis machining allows for the tool to approach the workpiece from virtually any direction. This capability is crucial for creating complex geometries and intricate details on PCB fixtures, which would be challenging, if not impossible, to achieve with more conventional setups. The added flexibility significantly reduces the need for multiple setups, which, in turn, minimizes errors and enhances overall precision.

High-Speed Machining (HSM) is another pivotal technique in the arsenal of advanced CNC machining. HSM combines high feed rates with high spindle speeds, drastically reducing machining time while maintaining exceptional surface finishes. This technique is particularly beneficial for PCB fixtures, where surface quality can directly impact the fixture’s performance. By minimizing the time the tool is in contact with the material, HSM also reduces thermal deformation, further enhancing the precision of the final product.

Adaptive Machining represents a leap forward in CNC technology, utilizing real-time feedback to adjust machining parameters on the fly. This dynamic approach allows for the compensation of variables such as tool wear or material inconsistencies, which can detract from the precision of CNC-machined parts. In the context of PCB fixtures, adaptive machining ensures that even over extended production runs, each fixture maintains the highest possible fidelity to the original design specifications.

Case Study: Implementing Micro-Machining for High-Density PCB Fixtures

A notable case study that underscores the efficacy of advanced CNC techniques involves the use of micro-machining for a series of high-density PCB fixtures. These fixtures, designed for a high-precision medical device, required intricate channels and cavities, with tolerances measured in micrometers. The implementation of micro-machining, coupled with 5-axis capabilities, allowed for the successful fabrication of these complex components, showcasing the unparalleled precision that advanced CNC machining techniques can achieve.

Quality Control Measures in CNC Machining for PCB Fixtures

The assurance of quality in CNC machining, particularly for PCB fixtures, is not merely a final step but a pervasive aspect of the entire manufacturing process. This section examines the comprehensive quality control measures that are integral to maintaining precision from the initial design phase through to the final inspection.

In-process Inspection plays a critical role in the quality control framework, involving continuous monitoring during the machining process. This proactive approach allows for immediate detection and correction of any deviations, ensuring that each fixture remains within the stringent tolerance thresholds required for PCB assembly.

Post-machining Inspection is equally critical, employing a variety of advanced measuring instruments and techniques to verify the precision of the machined fixtures. Tools such as CMMs (Coordinate Measuring Machines) and laser scanners provide highly accurate measurements of dimensions, tolerances, and surface finishes, confirming that the fixtures meet all specified criteria.

Statistical Process Control (SPC) is another cornerstone of quality assurance in CNC machining. SPC involves the statistical analysis of data collected during the manufacturing process to identify and control variability. By applying SPC to the production of PCB fixtures, manufacturers can ensure a consistent level of precision across all fixtures, even in high-volume production environments.

Data Table: Common Quality Control Metrics and Standards in CNC Machining

| Quality Metric | Description | Importance for PCB Fixtures |

|---|---|---|

| Dimensional Accuracy | Measures the degree to which the machined part conforms to the specified dimensions. | Essential for ensuring that the PCB fits perfectly within the fixture, affecting the assembly and final product quality. |

| Surface Finish | Quantifies the smoothness or texture of the machined surface. | Critical for electrical conductivity and ensuring no damage to the PCB during handling. |

| Tolerance | Indicates the allowable limit of variation in a physical dimension. | Vital for the functionality and reliability of PCB fixtures, affecting component fit and connectivity. |

| Parallelism | Assesses the degree to which two surfaces are parallel to each other. | Ensures that the PCB is held flat and securely, impacting the accuracy of soldering and assembly processes. |

Addressing Thermal Expansion and Its Effects on Precision

Thermal expansion presents a significant challenge in maintaining the precision of CNC-machined parts, including PCB fixtures. As materials are subjected to the heat generated during the machining process, they undergo expansion, which can lead to deviations from the intended dimensions and geometries. This section delves into the mechanisms of thermal expansion in materials commonly used in CNC machining and discusses strategies to mitigate its impact on the precision of PCB fixtures.

Materials expand at different rates when exposed to heat, a property quantified by the coefficient of thermal expansion (CTE). Understanding the CTE is crucial for predicting the material’s behavior under machining conditions and planning accordingly to minimize its effects. For instance, metals typically have higher CTEs than polymers, meaning they are more susceptible to dimensional changes due to temperature variations during machining.

Data Table: Coefficient of Thermal Expansion for Various Materials

| Material | Coefficient of Thermal Expansion (µm/m-K) |

|---|---|

| Aluminum 6061 | 23.6 |

| Brass C36000 | 20.5 |

| Stainless Steel 304 | 17.2 |

| Titanium Grade 5 | 8.6 |

| Polycarbonate | 65 |

| Acrylic | 70 |

This table underscores the importance of selecting materials with suitable CTEs for the specific requirements of PCB fixtures, especially when high precision is paramount. For example, while polymers like polycarbonate and acrylic offer certain advantages, their high CTEs might not be ideal for applications where thermal stability is critical.

To combat the challenges posed by thermal expansion, several strategies can be employed in the CNC machining process. Temperature-controlled machining environments can help maintain a constant temperature, reducing the risk of thermal expansion. Additionally, adjusting machining parameters such as cutting speed and feed rate can help manage the heat generated during machining, thereby minimizing its impact on the material.

The Role of Software in Achieving High Precision in CNC Machining

The integration of advanced software into CNC machining processes has been a cornerstone in achieving and maintaining high levels of precision. From the initial design phase using CAD (Computer-Aided Design) software to the final machining stages controlled by CAM (Computer-Aided Manufacturing) software, these digital tools play a critical role in optimizing the machining process for precision.

Software advancements have enabled more accurate simulations of the machining process, allowing engineers to anticipate potential issues and adjust the machining strategy accordingly. For instance, toolpath optimization can significantly reduce the likelihood of errors by ensuring the most efficient and effective cutting sequences, thereby improving the overall precision of the CNC-machined PCB fixtures.

Case Study: Software Optimization for Complex PCB Fixture Machining

A compelling case study in the application of software in CNC machining involves the production of complex PCB fixtures for an aerospace application. The intricate design required precise channels and cavities with extremely tight tolerances. Through the use of advanced CAM software, the machining process was optimized to account for the tool’s wear over time, ensuring that each fixture met the stringent aerospace industry standards. This optimization not only improved the precision of the fixtures but also enhanced the overall efficiency of the production process, showcasing the pivotal role of software in achieving high precision in CNC machining.

Custom CNC Solutions for Complex PCB Fixture Designs

As the complexity of electronic devices escalates, so does the complexity of the PCB fixtures required for their assembly and testing. Custom CNC solutions have become indispensable in addressing the unique demands of these intricate designs. This section highlights the bespoke approaches in CNC machining that cater to the nuanced requirements of complex PCB fixtures, emphasizing the synergy between innovative design, precision machining, and custom tooling.

The customization process begins at the design phase, where each fixture is meticulously engineered to meet specific requirements. This often involves collaboration between design engineers and CNC machining experts to ensure that the fixture not only holds the PCB securely but also aligns with the manufacturing process’s precision demands. Custom tooling is frequently developed to achieve the intricate details and tight tolerances required for these fixtures, which standard tooling might not accommodate.

Adapting CNC Machining Strategies for Custom Fixtures

For each unique PCB fixture design, CNC machining strategies must be adapted to accommodate the specific features and requirements. This might involve the use of specialized cutting tools, custom jigs, and fixtures to hold the workpiece securely, or advanced machining techniques such as micro-machining for extremely small features. The goal is to achieve the highest possible precision while maintaining efficiency and cost-effectiveness in the production process.

Data Table: Comparison of Traditional vs. Custom CNC Solutions

| Feature | Traditional CNC Solutions | Custom CNC Solutions |

|---|---|---|

| Design Flexibility | Limited by standard tooling and processes | Highly adaptable to specific project requirements |

| Machining Precision | Standard precision levels | Enhanced precision through specialized tooling and techniques |

| Production Time | Generally faster for standard parts | Longer due to customization, but with potentially higher quality |

| Cost | Lower for high-volume standard parts | Higher due to customization and specialized processes |

This table underscores the trade-offs between traditional and custom CNC solutions. While custom CNC machining might require more time and investment upfront, the payoff in terms of precision and adaptability to complex designs can be significant, especially for high-tech applications where the margin for error is minimal.

Conclusion

The journey toward solving precision issues in China’s custom CNC machining for complex PCB fixtures is both challenging and rewarding. It encompasses a broad spectrum of considerations, from the initial material selection and the adoption of advanced machining techniques to the implementation of rigorous quality control measures and the use of sophisticated software for optimization. Custom CNC solutions, with their ability to tailor the machining process to the specific demands of complex PCB fixtures, stand at the forefront of this endeavor.

As we look to the future, the continuous advancement in CNC machining technology, coupled with an ever-increasing emphasis on precision, promises to further elevate the capabilities and possibilities in the manufacturing of PCB fixtures. The intersection of innovation, precision, and customization will undoubtedly continue to drive the evolution of CNC machining, ensuring that even the most complex and demanding PCB fixture designs can be realized with the highest levels of precision.

Other Articles You Might Enjoy

- Elevating Precision Standards through Chamfer in CNC Machining

1. Introduction: The Pursuit of Unparalleled Precision In the realm of CNC machining, precision is paramount. This section introduces the article by exploring the significance of precision in manufacturing and…

- Precision Prowess: Unveiling the Advantages of China CNC Machining

1. Introduction: The Role of Precision in Manufacturing Excellence In this introductory section, we delve into the critical role that precision plays in manufacturing and set the stage for an…

- Revolutionizing CNC Machining for Complex Aerospace Assemblies

Introduction to CNC Machining in Aerospace Assemblies Computer Numerical Control (CNC) machining represents a significant technological development playing a notable role in the creation of complex aerospace assemblies. CNC machining…