Introduction to CNC Machining in China

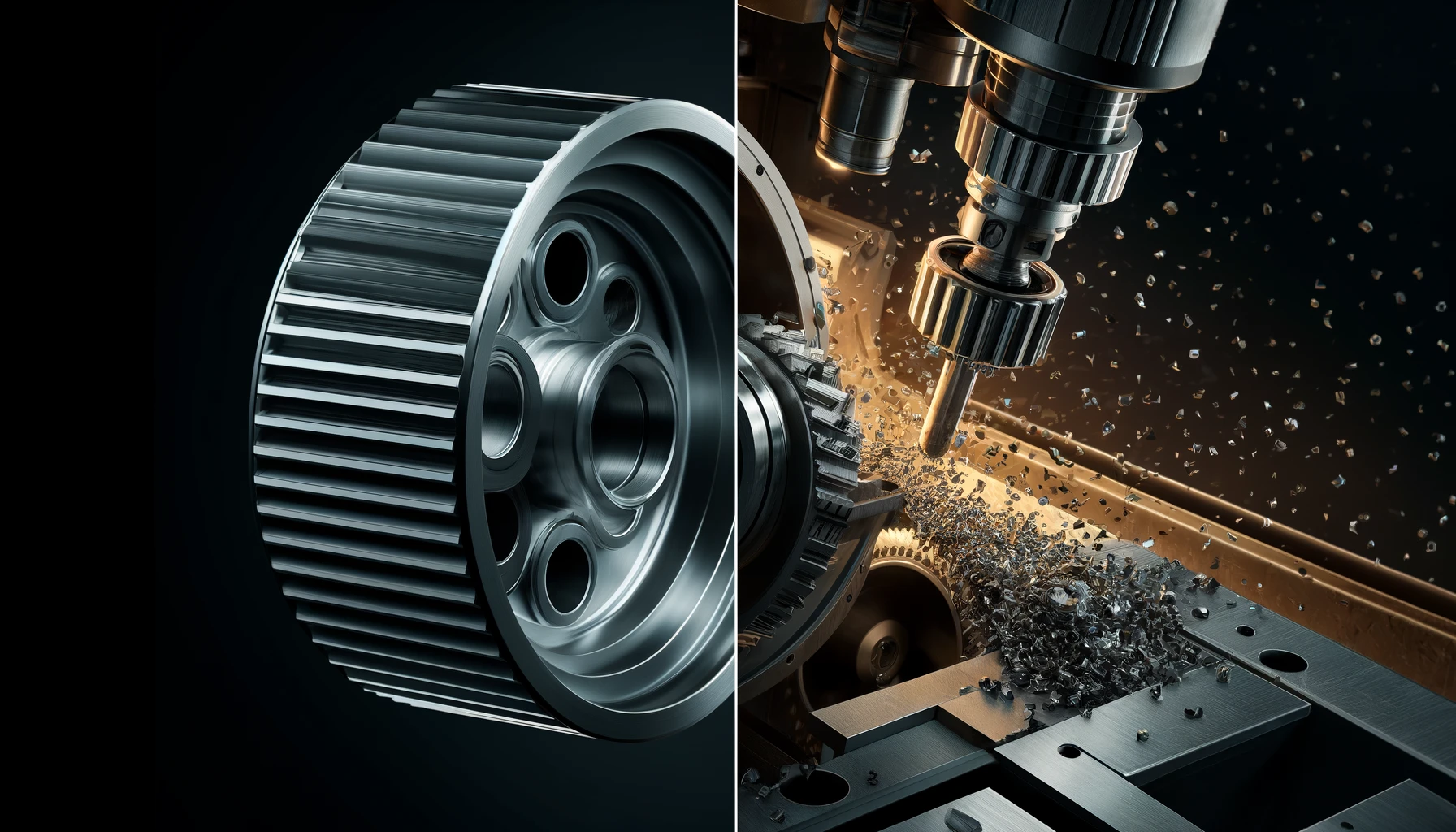

The advent of CNC (Computer Numerical Control) machining in China marks a significant milestone in the global manufacturing landscape. With a robust industrial foundation and a relentless pursuit of technological innovation, China has emerged as a frontrunner in providing CNC machining services that cater to a broad spectrum of industries, including automotive, aerospace, robotics, and more. At the heart of these services lies the production of critical components like timing pulleys, which are indispensable for applications demanding precise synchronization and timing accuracy.

Timing pulleys, integral to the smooth operation of timing belt systems, ensure the synchronous transmission of motion between different parts of a machine. Their precise manufacturing is paramount, as even the slightest deviation can lead to significant errors, affecting the overall performance of a system. China CNC machining services, known for their precision, efficiency, and reliability, have become a preferred choice for producing these intricate components. Leveraging advanced machinery, skilled technicians, and stringent quality control measures, these services ensure that each timing pulley adheres to the highest standards of quality and performance.

What Are the Unique Features of Timing Pulleys That Challenge CNC Machining?

Timing pulleys come with a set of unique geometric and material characteristics that pose significant challenges to CNC machining processes. These challenges are primarily due to the intricate tooth profiles required for meshing with timing belts and the stringent accuracy needed to maintain mechanical synchronization.

Unique Features of Timing Pulleys:

- Complex Tooth Geometry: The tooth profile of timing pulleys, often defined by specific standards like ISO or ANSI, requires precise machining to ensure proper belt engagement and prevent slippage.

- Material Hardness and Machinability: Timing pulleys are made from a variety of materials, each with different properties affecting their machinability. For example, steel pulleys offer high strength but are more challenging to machine than aluminum pulleys, which are softer but less durable.

- Surface Finish Requirements: The surface finish of the tooth profile and pulley body can significantly impact the performance of the timing belt system. A smoother finish reduces belt wear but requires more precise machining techniques.

Challenges in CNC Machining Timing Pulleys:

- Maintaining Dimensional Accuracy: The precision required for the tooth profile and overall dimensions of the timing pulley is paramount. Any deviation can lead to improper belt tension or alignment, resulting in system failure.

- Tool Wear and Material Removal Rates: The hardness of materials commonly used for timing pulleys, such as steel, can lead to increased tool wear, affecting the machining process’s efficiency and the final product’s quality.

- Machining Efficiency vs. Quality: Achieving a balance between efficient material removal and the high-quality finish required for timing pulleys is a critical challenge. High-speed machining can lead to quicker production times but may compromise the surface quality and dimensional accuracy.

To address these challenges, CNC machining services in China employ a combination of advanced machinery, specialized tooling, and expert programming. The use of multi-axis CNC machines allows for the intricate tooth profiles to be machined with high precision, while sophisticated CAM (Computer-Aided Manufacturing) software enables the optimization of machining paths, reducing tool wear and ensuring the required surface finish.

How Do Material Choices Affect the CNC Machining of Timing Pulleys?

The selection of materials for timing pulleys significantly impacts the CNC machining process, influencing everything from tool wear to machining speed and the final product’s durability. Common materials include aluminum, steel, and various polymers, each offering different advantages and challenges.

Material Comparison Table:

| Material | Hardness | Machinability | Durability | Application |

|---|---|---|---|---|

| Aluminum | Low | High | Moderate | Light-duty applications, where weight is a concern |

| Steel | High | Moderate | High | Heavy-duty applications requiring high strength |

| Polymers | Variable | High | Variable | Applications needing corrosion resistance and lower weight |

Case Study: Machining Aluminum vs. Steel Timing Pulleys

In a comparative study between machining aluminum and steel timing pulleys, it was found that aluminum pulleys could be machined faster due to the material’s lower hardness, resulting in less tool wear and lower machining costs. However, steel pulleys, while more time-consuming and costly to machine, offered superior durability and strength, making them suitable for more demanding applications.

Project Example: Aerospace Aluminum Timing Pulley

An aerospace project required a lightweight yet durable timing pulley for a new drone design. Aluminum 7075 was selected for its excellent strength-to-weight ratio, crucial for optimizing the drone’s flight capabilities.

Challenges and Solutions:

- Machining Precision: High-speed CNC techniques minimized heat buildup, essential for maintaining aluminum’s structural integrity.

- Tooling: Coated carbide tools were used to enhance tool life and surface finish.

- Quality Assurance: Dimensional accuracy was verified with a CMM, ensuring the pulley met the precise specifications required for the drone’s operation.

Outcome:

The project successfully produced a pulley that met the aerospace application’s stringent requirements, demonstrating the importance of material choice and specialized machining strategies in creating components that meet specific performance criteria. This case highlights China’s CNC machining services’ ability to deliver high-quality, custom solutions through careful material selection and advanced machining techniques.

What Advanced CNC Techniques Are Employed for Precision Machining of Timing Pulleys?

The precision required for timing pulley machining necessitates the use of advanced CNC techniques. These techniques not only ensure the accuracy of the tooth profile and overall dimensions but also enhance the efficiency of the machining process.

Advanced CNC Techniques:

- High-Speed Machining (HSM): Allows for faster material removal rates, reducing production times while maintaining precision.

- 5-Axis CNC Machining: Offers the ability to machine complex shapes in a single setup, improving accuracy and reducing the need for multiple setups.

- Tool Path Optimization: Advanced CAM software algorithms optimize tool paths, reducing tool wear and ensuring consistent quality.

Data Table: Impact of Advanced Techniques on Machining Efficiency

| Technique | Material Removal Rate | Setup Reduction | Tool Wear Impact | Accuracy Improvement |

|---|---|---|---|---|

| High-Speed Machining | High | N/A | Reduced | Moderate |

| 5-Axis CNC Machining | Moderate | Significant | Moderate | High |

| Tool Path Optimization | Moderate | N/A | Significant | High |

Example: High-Precision Steel Timing Pulley for Industrial Conveyor System

A manufacturer required a durable timing pulley for a heavy-duty industrial conveyor. The challenge was to ensure the pulley’s teeth had the precision necessary for smooth operation under high loads.

- Solution: 5-axis CNC machining was employed to create the complex tooth profile in a single setup, ensuring high dimensional accuracy. Advanced CAM software optimized the tool paths, reducing wear and improving efficiency.

- Outcome: The pulley met all specifications for the demanding industrial application, demonstrating the value of advanced CNC techniques in producing durable, high-precision components.

How Is Quality Control Ensured During the Machining of Timing Pulleys?

Quality control is paramount in the machining of timing pulleys, given their critical role in mechanical systems. China’s CNC machining services implement rigorous quality control protocols to ensure each pulley meets stringent standards.

Quality Control Measures:

- Dimensional Inspection: Utilizing precision measurement tools like CMMs (Coordinate Measuring Machines) to verify the dimensions and geometry of the pulleys.

- Surface Finish Testing: Employing profilometers to measure the surface roughness, ensuring it meets the required specifications.

- Performance Testing: Subjecting the pulleys to operational tests to simulate real-world conditions, ensuring they perform as expected under load.

Example: Quality Assurance for Automotive Timing Pulleys

For an automotive project, timing pulleys required exceptional precision to ensure engine timing accuracy.

- Quality Control Measures: After machining, each pulley underwent CMM inspection for dimensional accuracy and surface profilometry to confirm the finish quality. Performance testing under simulated engine conditions verified operational reliability.

- Outcome: The comprehensive QC approach ensured the pulleys met the automotive industry’s high standards, contributing to engine performance and longevity.

Can Customization of Timing Pulleys Be Achieved Through CNC Machining?

Customization stands as a cornerstone in the realm of CNC machining, particularly for components like timing pulleys, where specific applications demand unique features. China’s CNC machining services excel in offering bespoke solutions, tailoring each aspect of the pulley to meet the exact requirements of diverse industrial applications.

Customization Capabilities:

- Variable Tooth Profiles: Custom tooth geometries can be machined to match unique belt designs or to optimize performance under specific conditions.

- Material Selection: Clients can choose from a wide range of materials based on the application’s needs, balancing factors like weight, strength, and environmental resistance.

- Integrated Features: Additional features, such as mounting flanges, keyways, or special bore sizes, can be precisely machined to facilitate seamless integration into existing systems.

Example: Customized Polymer Timing Pulley for Medical Equipment

A medical device manufacturer needed a customized, lightweight timing pulley for a new diagnostic machine. The pulley required a unique tooth profile for precise motion control and compatibility with the device’s belt system.

- Customization Process: The pulley was designed using a high-performance polymer for its lightweight and low-noise characteristics, essential in a medical setting. CNC machining with specialized tooling was used to achieve the intricate tooth profile and integrated hub design.

- Outcome: The customized pulley enhanced the diagnostic machine’s performance by providing precise, quiet operation, showcasing CNC machining’s capability to produce tailored components for critical applications.

What Role Does Automation Play in Enhancing CNC Machining Efficiency for Timing Pulleys?

Automation in CNC machining not only elevates production efficiency but also enhances the consistency and quality of the machined timing pulleys. China’s adoption of automated processes in CNC machining setups represents a leap towards unparalleled productivity and reliability.

Automation Techniques:

- Robotic Loaders and Unloaders: Automate the loading and unloading of workpieces, reducing downtime between machining cycles.

- Automated Tool Changers: Enable the use of multiple cutting tools in a single setup without manual intervention, optimizing the machining process for complex parts like timing pulleys.

- In-line Quality Control Systems: Automated inspection systems integrated into the machining process provide real-time quality control, detecting and correcting deviations immediately.

Data Table: Efficiency Gains from Automation

| Automation Feature | Time Savings | Error Reduction | Productivity Increase |

|---|---|---|---|

| Robotic Loaders/Unloaders | High | Moderate | High |

| Automated Tool Changers | Moderate | High | Moderate |

| In-line Quality Control | Moderate | Very High | High |

Other Articles You Might Enjoy

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…