Understanding Your Requirements

What Are Your Specific Needs?

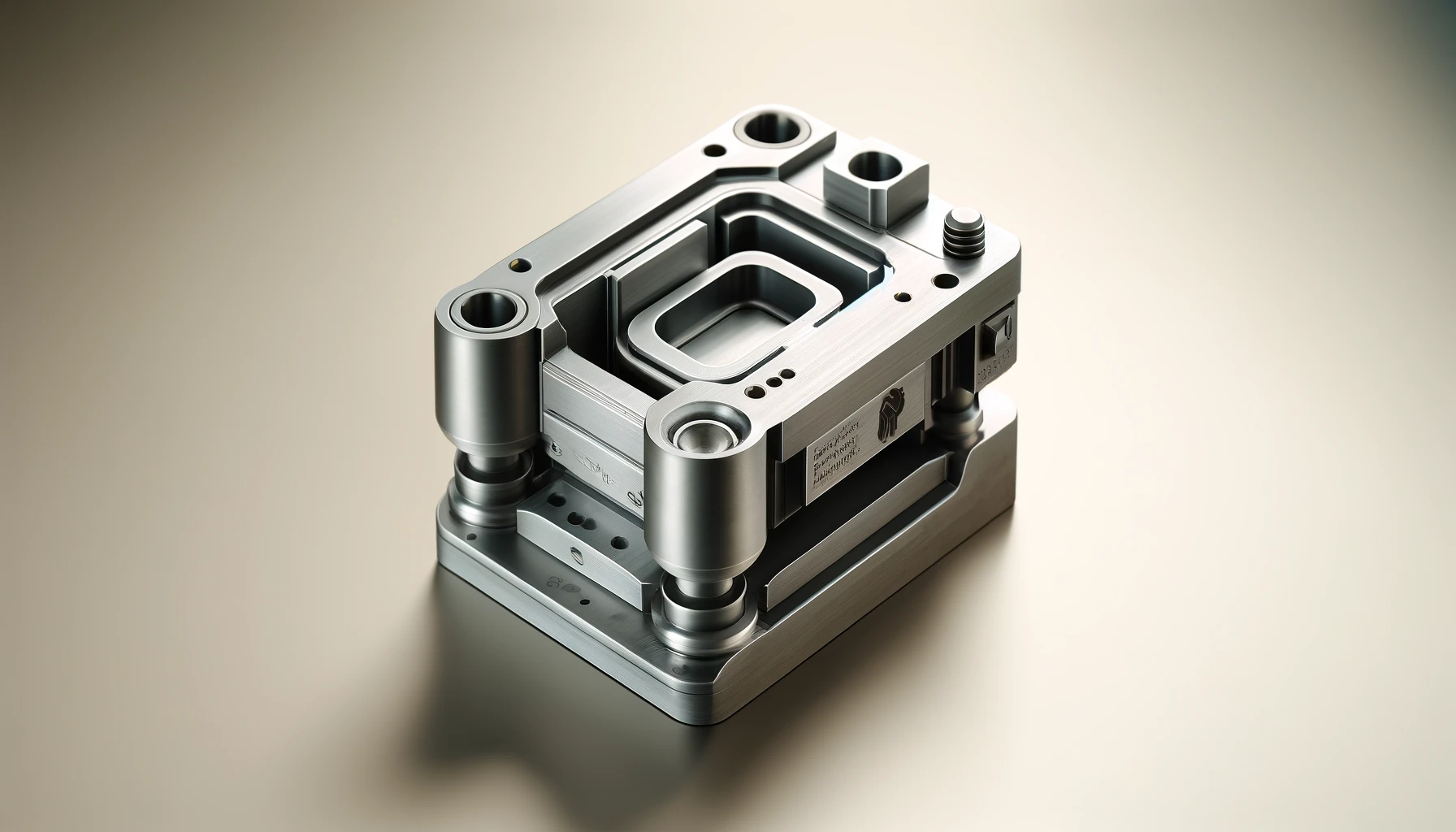

Before selecting a CNC machining company, it’s essential to define your specific needs clearly. This includes detailing the specifications and requirements for your steel stamping dies. Understanding the volume of production and the expected timeline is crucial. A clear understanding of your needs will help you communicate effectively with potential suppliers and ensure they can meet your requirements.

Steel stamping dies can vary significantly based on their application, whether for automotive, electronics, or other industries. Each application may have unique requirements in terms of precision, durability, and complexity. For instance, automotive stamping dies might require higher durability due to the high-volume production demands, while electronics stamping dies may need higher precision for intricate designs.

What Material Specifications Are Required?

Knowing the specific type of steel and any special material properties needed for your dies is another critical factor. Different applications might require different types of steel with specific characteristics. For example, high-carbon steel might be necessary for its hardness and wear resistance, while stainless steel could be required for its corrosion resistance.

Heat treatment processes such as quenching, tempering, or nitriding can significantly impact the material properties and, consequently, the performance of the stamping dies. Surface finish requirements also play a vital role in determining the quality and longevity of the dies. A smooth surface finish can reduce friction and wear, leading to a longer lifespan for the dies.

Evaluating Technical Capabilities

What Equipment and Technology Does the Company Use?

The type of equipment and technology used by a CNC machining company is a direct indicator of their capability to produce high-quality steel stamping dies. Advanced CNC machines, particularly those with five-axis capabilities, allow for greater precision and complexity in the machining process. These machines can handle intricate geometries and maintain tight tolerances, which are often required for high-quality stamping dies.

- Table: Types of CNC Machines and Their Capabilities

| Machine Type | Axes | Precision Level | Suitable For |

|---|---|---|---|

| Three-Axis CNC | 3 | Moderate | Simple geometries and operations |

| Four-Axis CNC | 4 | High | Complex geometries and milling |

| Five-Axis CNC | 5 | Very High | Intricate shapes and tight tolerances |

| Swiss-Type Lathe | Up to 8 | Extremely High | Small, precise parts |

| Vertical Machining Center | 3-5 | High | Versatile for various tasks |

| Horizontal Machining Center | 3-5 | High | Large and complex parts |

How Skilled Is the Workforce?

The expertise of the machinists and engineers is equally important. Skilled professionals can optimize the machining parameters, troubleshoot issues, and ensure that the final product meets the required specifications. Look for companies that provide continuous training and have a robust process for knowledge transfer and skill enhancement.

Experience in handling similar projects is a significant advantage. A company with a proven track record in machining steel stamping dies will likely have encountered and overcome various challenges, making them more reliable partners.

Quality Assurance and Control

What Quality Control Measures Are in Place?

Quality assurance is critical in CNC machining, especially for precision parts like steel stamping dies. Investigate the company’s quality control processes, including their certifications such as ISO 9001. Certifications indicate a commitment to maintaining high standards of quality management.

In-process inspections and final quality checks ensure that each part meets the specified requirements. Advanced inspection tools like coordinate measuring machines (CMMs), laser scanners, and other precision instruments are used to verify dimensions and surface finishes.

- Case Study: Aerospace Industry

An aerospace manufacturer needed steel stamping dies with extremely tight tolerances. They partnered with a CNC machining company that had a comprehensive quality assurance process, including in-process inspections and CMM verification. This approach ensured that every die met the stringent aerospace standards, highlighting the importance of robust quality control measures.

How Does the Company Handle Defects and Rework?

Understanding a company’s policy on addressing defects and rework is crucial. Even with the best processes, occasional defects can occur. A reliable company should have a clear procedure for identifying and rectifying defects without significant delays. Past performance in maintaining high-quality standards and handling defects effectively can provide insights into their reliability.

Assessing Cost and Value

What Are the Costs Involved?

Obtaining detailed quotes from multiple companies is necessary for a comprehensive cost comparison. Consider the cost in relation to the quality and reliability of the services offered. The cheapest option is not always the best, as lower costs can sometimes indicate compromises in quality or service.

- Table: Cost Comparison of CNC Machining Services

| Company Name | Quoted Price | Inclusions | Exclusions | Lead Time | Quality Rating |

|---|---|---|---|---|---|

| Precision Machining Co. | $5000 | Tooling, Inspection | Shipping, Taxes | 4 weeks | 9/10 |

| HighTech CNC | $4500 | Tooling | Shipping, Taxes, Rework | 5 weeks | 8/10 |

| Advanced Machining | $6000 | Full Service | Taxes | 3 weeks | 9.5/10 |

| Reliable CNC | $5500 | Tooling, Shipping | Taxes | 4 weeks | 9/10 |

| Budget CNC | $4000 | Basic Machining | Inspection, Shipping | 6 weeks | 7/10 |

| Premium Machining | $6500 | Full Service, Shipping | Taxes | 3 weeks | 9.8/10 |

| Standard CNC | $5200 | Tooling, Inspection | Shipping, Taxes | 4 weeks | 8.5/10 |

| Economical Machining | $4300 | Basic Machining | Inspection, Shipping | 5 weeks | 7.5/10 |

What Additional Value Does the Company Provide?

Beyond the basic machining services, look for value-added services such as design support, prototyping, and post-production services. These services can significantly enhance the overall value of the partnership. For instance, a company that offers design optimization can help improve the manufacturability and performance of your stamping dies.

- Case Study: Consumer Electronics

A consumer electronics company required highly precise stamping dies for producing small, intricate components. They partnered with a CNC machining company that provided extensive design support and prototyping services. This collaboration led to the optimization of the die design, reducing production costs and improving the quality of the final products. The value-added services provided by the CNC company played a crucial role in the success of the project.

What Are the Long-Term Cost Implications?

Consider the total cost of ownership, including maintenance, durability, and potential downtime. Higher upfront costs might lead to lower long-term expenses if the quality and durability of the dies are superior. Evaluate the company’s ability to provide consistent quality and support over time, which can reduce the need for frequent replacements or repairs.

How Transparent Is the Pricing Structure?

Ensure that the company’s pricing structure is transparent and includes all potential costs. Avoid companies with hidden fees or unclear terms that could lead to unexpected expenses. Request a breakdown of costs to understand what you are paying for in detail. Transparent pricing helps in making informed decisions and avoiding budget overruns.

Customer Support and Communication

How Effective Is Their Communication?

Effective communication is essential for a successful partnership. Evaluate the responsiveness and clarity of communication from the company. Regular updates and a transparent communication process help ensure that you are always informed about the progress of your project.

What Is Their Track Record for Customer Support?

Investigate the company’s history of customer support and satisfaction. Reviews and testimonials from previous clients can provide valuable insights into their reliability and commitment to customer satisfaction. A company with a strong track record in customer support is more likely to address any issues promptly and effectively.

By following these guidelines and thoroughly evaluating potential CNC machining companies, you can make an informed decision and select the right partner for your steel stamping die production needs.

Related Posts

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Innovative CNC Machining for the Aerospace Sector

Innovative CNC Machining for the Aerospace Sector CNC machining, an abbreviation for Computer Numerical Control machining, stands as a vital player within today's manufacturing scene. Utilizing computer-generated code to control…

- Streamlining CNC Machining for Lightweight Metals( alloy steel Veromca)

In recent years, computer numerical control (CNC) machining has emerged as a highly efficient method for processing various types of materials—including lightweight metals. Efficient in operation and precise in execution,…

- Tool Steel Grades for CNC Machining: A Comprehensive Comparison

Introduction to Tool Steel in CNC Machining CNC (Computer Numerical Control) machining denotes a process employed in manufacturing where pre-programmed computer software manages the movement of factory machinery and tools.…

- What Material Properties Need to Be Considered When CNC Machining Stainless Steel Flanges?

The CNC machining of stainless steel flanges requires a profound understanding of the material's properties to ensure high-quality, precision outcomes. This article delves into the critical material properties that impact…

- Affordable CNC Machining Solutions in Aluminum: Rapid Quotes

CNC Machining: An Integral Part of Modern Manufacturing Computer Numerical Control (CNC) machining is a vital aspect of contemporary manufacturing, providing precision and efficiency in production processes. CNC machines use…