In recent years, computer numerical control (CNC) machining has emerged as a highly efficient method for processing various types of materials—including lightweight metals. Efficient in operation and precise in execution, CNC machines reshape the field of metal production by offering unparalleled precision and consistency.

One subset that benefits significantly from CNC machining is the manufacturing sector dealing with lightweight metal alloys. These include aluminum, magnesium, and titanium—materials known for their strength-to-weight ratio, making them ideal candidates for aerospace, automotive, and medical applications, among others. However, when these metals are plated with chrome—a heavy, corrosion-resistant coating—that protective layer may need to be removed at some point.

Removing Chrome from Metal Using CNC Techniques:

Before delving into how to remove chrome from metal using CNC techniques, it’s essential to understand why this process could be necessary. While chrome offers protection, it can occasionally decrease the component’s performance or have aesthetical implications due to its wear over time.

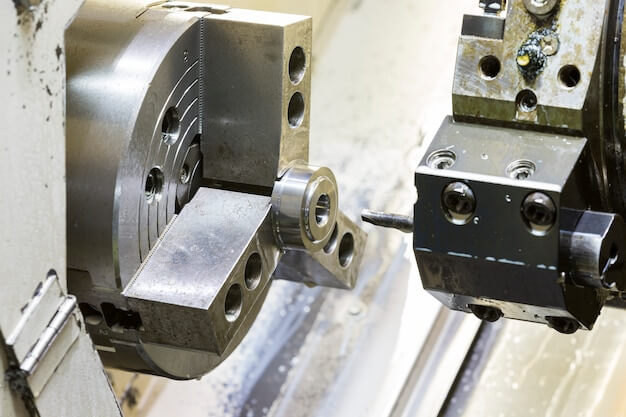

The removal of chrome coating usually involves chemical etching or abrasive methods, but these techniques often harm the underlying material. Hence, where precision matters, as with lightweight metals, CNC machining comes into play. It deploys mechanical methods which ensure accurate, consistent, high-quality results without damaging the base material itself.

To carry out this procedure, the CNC machine uses specific milling tools tailored to grind off the thin layer of chrome without impacting the integrity of the metal beneath it. Depending on the size and shape of the piece, different tools such as flat end mills or ball-nose end mill cutters may be usedamidastrobe. Thanks to the controlled movements provided by the automation technology of CNC machines, this process ensures exactness and minimal waste.

Broader Applications of Lightweight Metal CNC Machining:

While removing chrome from metal is just one aspect of what CNC machines can do with lightweight metals, there’s more to their application repertoire. For instance, these machines excel at processing metal alloys for intricate designs and prototypes that demand high precision.

CNC machining also plays an integral role in processes such as turning, milling, routing, and drilling of lightweight metals—all critical activities in industries ranging from aerospace to electronics. Moreover, the adaptive and modular nature of CNC machines makes them ideal for providing customized solutions tailored to specific production needs.

Concluding Note:

In essence, CNC machining reinforces its position in today’s digital manufacturing sphere through its multi-disciplinary capabilities, achieving reliable results on materials like lightweight metals or even when detailed tasks like chrome removal is required. The technology accelerates efficiency by reducing waste and errors while augmenting productivity—a boon for any sector relying heavily on metal components.

Therefore, it’s advantageous for businesses involved in lightweight metal production to capitalize on the potential of CNC machining—not only for standard procedures but also for specialized tasks like removing chrome from metal. In doing so, they equip themselves with a toolset ready to tackle their industry’s evolving demands effectively and sustainably.

Other Articles You Might Enjoy

- The Pros and Cons of Using Copper Alloys in CNC Machining Projects

Introduction to Copper Alloys and CNC Machining In the realm of materials suitable for manufacturing operations, copper alloys have emerged as a viable contender. Noted for their excellent thermal conductivity,…

- CNC Machining: Mastering Chrome Removal From Lightweight Metals(non ferrous metals Moses)

CNC (Computer Numerical Control) machining plays an indisputable role in various industries, notably for its unrivaled precision and ease of production. A common application is the production of lightweight metals…

- CNC Machining in Microelectronics: Material Precision for Component Miniaturization

Introduction to CNC Machining in Microelectronics CNC (Computer Numerical Control) machining stands as a cornerstone in the realm of microelectronics, offering unparalleled precision in the fabrication of components. This technique…