The Role of CNC Machining in Developing High-Efficiency Electric Motors

Computer numerical control (CNC) machining plays a crucial role in the development of high-efficiency electric motors. It is an advanced technique that involves the use of computers to control machine tools, enabling precise cutting and shaping of metal parts needed for these motors. This technology can significantly enhance the performance of electric motors by ensuring tight tolerances, superior finishes and intricate shapes necessary for efficient operation. The relationship between CNC machining and electric motor efficiency lies in its ability to produce copper windings – an essential component that affects the overall performance and functionality of the motor. Precisely machined copper grades assist in minimizing energy loss, amplifying coil density and improving heat dissipation, thus fostering improved motor efficiency.

- CNC Machining: A manufacturing process where pre-programmed computer software directs movement of factory machinery and tools.

- Electric Motor Efficiency: Defined as the ratio of usable shaft power to electrical input power, it indicates how effectively the motor converts electrical energy into mechanical work.

- Copper Winding: These are coils made from copper wire that when energized create a magnetic field driving the rotor of the motor.

Understanding CNC Machining in Engineering

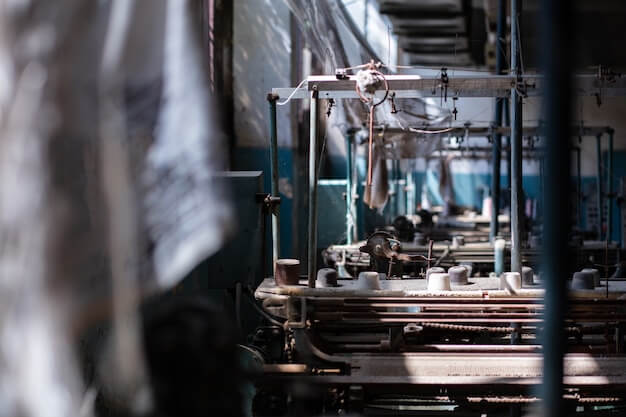

In engineering, Computer Numerical Control or CNC machining refers to a process used in the manufacturing industries that involves the use of computers to control machine tools. Tools that can be controlled in this manner include lathes, mills, routers and grinders. It plays an instrumental role because it allows for precision parts to be produced consistently and efficiently, particularly integral in developing high-efficiency electric motors.

The importance of CNC machining in manufacturing manifests itself in several ways, such as:

- Consistency: Unlike manual machining, CNC machines follow the same program every time they operate; ensuring each manufactured part is exactly the same as the last.

- Precision: CNC machines execute very fine movements down to fractions of a millimeter – impossible to replicate accurately by hand.

- Versatility: The ability to change the entire setup just by changing the software programming allows manufacturers to create various types of components without requiring mechanical reconfiguration.

Therefore, understanding CNC machining offers significant advantages from a manufacturing standpoint, especially when producing complex products like efficient electric motors which demand customization, consistency, and precise execution.

Deep Dive into Electric Motors

An electric motor is a device that converts electrical energy to mechanical energy, primarily through the interaction between its magnetic field and the winding currents. In rudimentary terms, it operates based on two key principles of electromagnetism: there exists an electromagnetic force along the conductor which carries current perpendicularly in a magnetic field, and like magnet poles repel while unlike attract. It begins functioning when voltage induces a current flow in the motor’s coil, subsequently creating a magnetic field that interacts with stationary magnets to generate force; this force spins the rotor, producing mechanical power.

In regards to efficiency, it’s essential because higher efficiency equates to lower operational costs due to reduced energy consumption. For instance, high-efficiency motors operate cooler, extending insulation life, reducing maintenance costs, and moreover, minimizing greenhouse gas emissions. This idea places the importance of CNC machining, particularly for shaping copper grades in motor components, as it increases precision, improves performance reliability, and optimizes efficiency. To subset:

- Improved Precision: Through specialized cutting tools, CNC machining cuts copper more accurately than traditional methods, leading to better fitted, functional parts.

- Reliable Performance: CNC produces consistent quality, ensuring every component performs reliably without compromising the overall motor function.

- Optimized Efficiency: Since copper has excellent conductivity, precise shaping maximizes energy transmission and minimizes losses, ultimately resulting in highly efficient motors.

- Copper is known for its excellent electrical conductivity, making it an ideal choice for electric motors.

- High electrical conductivity allows for efficient power transmission and reduces energy losses in the motor.

- Copper also exhibits high thermal conductivity, which helps in dissipating heat generated during motor operation.

- Efficient heat dissipation prevents overheating and ensures optimal motor performance and longevity.

- Copper grades used in electric motors possess good mechanical strength, allowing them to withstand the mechanical stresses and vibrations experienced during motor operation.

- This ensures the structural integrity and reliability of the motor components.

- Copper has good corrosion resistance, protecting the motor components from environmental factors and extending their lifespan.

- Corrosion resistance is particularly important in motors used in harsh or corrosive environments.

- Copper is readily available and has excellent machinability, making it easy to manufacture motor components with precision.

- Its malleability allows for complex shapes and intricate designs, enabling efficient motor construction.

- Intricate Cutting Tasks: CNC machines can perform precise cuts regardless of complexity on copper components, ensuring accurate construction of parts for high-efficiency motors.

- Complex 3D Shaping: CNC machines have advanced capabilities to form intricate 3D shapes from copper materials. This facilitates designing efficient motor parts with improved energy performance.

- C10100: High purity level with 99.99% copper content. Boasts superior conductivity but slightly difficult to machine due to softness.

- C11000: Contains about 99.9% copper with small amounts of oxygen. Less soft than C10100 making it easier to shape and machine, albeit with marginally reduced conductivity.

- CNC machining enables precise control for processing complex shapes, optimizing motor efficiency.

- Different grades of copper, like C10100 and C11000, offer varying benefits; they are well-suited to heat dissipation applications needed for these efficient motors.

- Advances in manufacturing technology and metallurgy can further push energy efficiency and reduce environmental impact.

- The Future of Medical Device Manufacturing: CNC Machined Stainless Steel

Introduction to Medical Device Manufacturing Medical device manufacturing is a crucial sector in the healthcare industry, powering a myriad of medical procedures and treatments worldwide. This field involves the design,…

- Precision CNC Machining for High-End Audio Equipment

Precision CNC Machining in High-End Audio Equipment Manufacturing Precision Computer Numerical Control (CNC) machining refers to a highly-advanced technology where computer-generated codes are used to operate factory machinery and tools.…

- Custom CNC Machining: Tailoring Solutions to Unique Engineering Challenges?

Introduction to Custom CNC Machining In the manufacturing world, innovations continually emerge and challenge traditional production methodologies. A significant game-changer has been Computer Numerical Control (CNC) machining — a process…

The Role of Copper in Electric Motors

Copper plays a crucial role in the development of high-efficiency electric motors. Here is an analysis of the different grades of copper used in electric motors:

1. Electrical Conductivity:

2. Thermal Conductivity:

3. Mechanical Strength:

4. Corrosion Resistance:

5. Manufacturing and Machinability:

The role of copper in electric motors is vital, providing high electrical and thermal conductivity, mechanical strength, corrosion resistance, and ease of manufacturing. To learn more about the applications of copper in CNC machining and motor manufacturing, you can refer to our Blog and Knowledge Base.

The Connection Between CNC Machining and High-Efficiency Electric Motors

Computer Numerical Control (CNC) machining plays a pivotal role in developing high-efficiency electric motors, particularly with the utilization of optimal copper grades. Among its numerous contributions is its precision and speed in fabrication processes that results in minimal material waste and energy consumption. Specific processes include intricate cutting tasks and complex 3D shaping which are rarely achievable by manual or semi-automatic machines.

Therefore, through these technical approaches, CNC machining contributes significantly to optimizing the functionality of electric motors while enhancing their efficiency.

Analysis of Different Grades of Copper for CNC Machining

In the development of high-efficiency electric motors, Computer Numerical Control (CNC) machining plays a profound role. One key element lies in the selection of materials used, amongst which are various grades of copper. This choice significantly influences the efficiency and durability of the motor.

Different copper grades have different properties that respond uniquely during the machining process. Commonly utilized grades include C10100, also known as Oxygen-Free Electronic (OFE), often celebrated for its excellent electrical conductivity, and C11000, also referred to as Electrolytic-Tough-Pitch (ETP), recognized for its balance between machinability and electrical conductance.

Through various studies and practical applications, it has been observed that grade C11000 generally offers more efficient results when used for CNC machining. The slight reduction in electrical performance is compensated by its higher workability, assuring the production of better formed and long-lasting parts.

Conclusion: Why Is This Important?

The role of CNC (Computer Numerical Control) machining in developing high-efficiency electric motors is critical. It was established that this advanced manufacturing technique not only enhances the energy efficiency and lower operating costs but also improves production volume and product quality, specifically when dealing with copper grades.

This knowledge holds significant implications especially for industries looking to optimize their operations around green technologies while keeping expenses at bay. Better understanding between complex technical principles and practical applications continues to be paramount as we continue progressing into an era where higher industrial efficiency is not just preferable, but becoming increasingly necessary.