Introduction to Medical Device Manufacturing

Medical device manufacturing is a crucial sector in the healthcare industry, powering a myriad of medical procedures and treatments worldwide. This field involves the design, production, and testing of various devices such as implants, prosthetics, diagnostics equipment, surgical instruments and more. More essentially, it signifies an essential bridge between innovative biomedical engineering solutions and practical applications that could potentially revolutionize patient care.

The impact of this industry on healthcare is multi-faceted. For instance:

- Providing critical tools for diagnosis, prevention and treatment of diseases

- Enhancing healthcare delivery through technology-assisted therapies or machine-aided surgeries

- Boosting research activities by enabling scientists with complex lab equipment and accurate measurement tools

Unquestionably, the quality of these manufactured devices directly affects patient safety and treatment effectiveness. That’s where CNC (Computer Numerical Control) machined stainless steel comes into play. By ensuring high precision, durability and resistance against corrosion, CNC machined stainless steel has indeed become one of the most trusted materials in medial device manufacturing.

The Concept of CNC Machined Stainless Steel

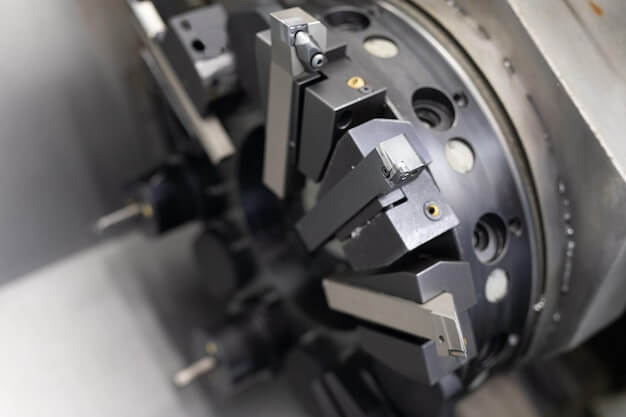

Computer Numerical Control (CNC) technology is a manufacturing process where pre-programmed computer software directs the movement of factory machinery and tools. This revolutionary digital approach eliminates the need for manual operation, enhancing precision, efficiency, and safety. Its applicability engaged various industries, including medical device manufacturing utilizing stainless steel. Noted for its high strength, resistance to corrosion, and durability, stainless steel remains an ideal choice in CNC machining processes.

An overview of why CNC machined stainless steel remains crucial revolves around the incessant demand in the production of medical devices. Owing to their contact with human bodies and fluids, these devices must guarantee ultimate safety, reliability, and longevity; qualities fulfilled by stainless steel. Below are some reasons:

- It offers superior biocompatibility making it safe for use in sensitive biological environments.

- Inherently sturdy yet malleable, this metal facilitates creation of complex designs without compromising on structural integrity.

- Its anti-corrosive nature ensures that the products will not rust or degrade over time, vital for prolonged patient usage.

To illustrate this point, consider the example of orthopedic implants such as hip replacement components. Their manufacture extensively adopts CNC machined stainless steel for unparalleled construction quality and life-span excellence.

Current State of Medical Device Manufacturing

The current spectrum of medical device manufacturing is widely characterized by the implementation of modern technologies, precision techniques, and robust materials. Foremost among these technologies is Computer Numerically Controlled (CNC) machining, a method that integrates software and automation for high precision device creation. CNC machined stainless steel in particular has gained popularity given its suitability for creating intricate and highly crucial devices like surgical instruments and dental prosthetics. Furthermore, there’s an increasing shift towards incorporating 3D printing technology, allowing manufacturers to seamlessly craft complex devices faster and cost-effectively.

- Ceramics, plastics, metals, including valuable ones such as gold and titanium, represent the most frequently used materials. Each chosen based on its unique properties aligning with the specific functional requirements of the intended medical device.

- In terms of techniques, beyond CNC machining and 3D Printing, laser cutting and electrical discharge machining (EDM) are integral parts in shaping and assembling medical devices. Laser-cutting promotes precise incisions while EDM specializes in manufacturing ultra-precise components often used in sensitive applications like pacemakers or insulin pumps.

The Future of CNC Machined Stainless Steel in Medical Device Manufacturing:

- CNC machined stainless steel is expected to play a crucial role in shaping the future of medical device manufacturing, offering high strength, chemical resistance, and hardness required for surgical implants and equipment used in the medical sector.

- For the future of medical device manufacturing, it is essential to consider the properties and industries suitable for stainless steel in CNC machining, as well as the critical factors for achieving high-quality machined parts with CNC machining to meet the stringent requirements of the medical industry.

Benefits of Using CNC Machined Stainless Steel for Medical Devices

The benefits of using Computer Numerical Control (CNC) machined stainless steel in manufacturing medical devices are expansive, enhancing both the production process and overall patient care. One key advantage lies in its exceptional precision; this technology enables manufacturers to fabricate intricate parts with an extraordinarily high degree of accuracy. For example, it is paramount in producing finer details necessary to create complex orthopedic implants or cardiovascular stents.

In addition, the robustness and longevity afforded by stainless steel make it a superior choice as these characteristics significantly reduce device malfunctions or breakdowns. This translates into enhanced durability for equipment like surgical tools or joint replacement hardware that must function flawlessly over time. Noteworthy too, is the cost-effectiveness of CNC machining, which efficiently produces large volumes at considerably lower costs in terms of energy consumption and waste production compared to traditional methods.

- Precision: Enables fabrication of intricate parts necessary for complex orthopedic implants or cardiovascular stents.

- Durability: Enhances equipment lifespan reducing possibility of breakdowns or malfunctions, especially crucial for surgical tools or joint replacement hardware.

- Cost-effectiveness: Efficiently generates large volumes with less energy consumption and waste, demonstrating significant economic advantages over traditional methods.

Cumulatively, the integration of CNC machined stainless steel in medical device manufacturing elevates the quality of patient care. It allows healthcare providers to precisely carry out complicated surgeries and treatments while ensuring long-term effectiveness, promoting improved patient outcomes and experiences.

Challenges in Implementing CNC Machined Stainless Steel in Manufacturing Process

Implementing CNC machined stainless steel into the manufacturing process poses several significant challenges. On a financial level, such an investment requires substantial capital due to the high cost of CNC machines and raw materials like stainless steel. Additionally, this technology demands solid technological infrastructure that many companies may lack. Stable power supply, advanced software systems suitable for integration with these machines, and physical space for equipment storage are among some of the infrastructural prerequisites.

- Financial Implications: The high upfront costs associated with purchasing state-of-the-art CNC machines and premium quality stainless steel create a substantial financial burden on manufacturers. This could particularly affect small-scale businesses operating under tight budgets.

- Technological Infrastructure Requirement: To run CNC machinery efficiently, manufacturers need considerable computing power and precisely designed software systems. Lacking these can lead to operational inefficiencies or production errors which would further compound their expenses.

- Training Need: Working with CNC machines is far more technical than conventional tools. Thus, staff training becomes essential to leverage the machine’s full potential and maintain safety protocols. However, arranging frequent skill-development sessions adds up to the overall expenditure.

In conclusion, while adopting CNC machined stainless steel presents certain challenges, strategic planning and smart investment could be the key to solving them. For instance, acquiring refurbished CNC machines instead of new ones might be a viable option for financially strained manufacturers. Similarly, leveraging government grants geared towards promoting technological advancements could ease the fiscal pressure. Hence, implementing this innovative process does not have to be problematic if approached systematically.

Conclusion: The Critical Transition Towards CNC Machined Stainless Steel in Medical Device Manufacturing

The inevitable shift towards the usage of CNC machined stainless steel in medical device manufacturing marks a pivotal advancement within the health sector. The importance of this transition lies not only in the improved precision and efficiency it introduces to production processes but also in its potential to revolutionize patient care.

-

Medical devices made from CNC machined stainless steel are characterized by their high durability, superior corrosion resistance, and exceptional strength-to-weight ratio – qualities that considerably enhance product lifespan and safety.

-

This advanced fabrication technique also enables mass customization, facilitating the creation of personalized implants and prosthetics tailored to individual patient specifications.

-

CNC machining negates the need for manual intervention, thus reducing human error, increasing speed of production, and lowering operating costs extensively.

In essence, the adoption of CNC machined stainless steel represents a significant step forward in delivering sophisticated, reliable, and affordable medical solutions, thereby propelling our healthcare industry into an era filled with unprecedented opportunities for growth and innovation.

Other Articles You Might Enjoy

- Exploring Bead Blasting In CNC Machining(cnc cutting tools Hale)

Bead blasting is a crucial technique applied extensively in the realm of Computer Numerical Control (CNC) machining. This process transforms the exterior aesthetics and surface quality of machined parts, augmenting…

- Comparing Machinability of Various Tool Steels: What's the Best Choice?

Understanding Tool Steels and their Machinability Tool steels are referred to as an extensive variety of carbon and alloy steels known for their distinctive hardness, abrasion resistance, and ability to…

- Understanding Bead Blasting in CNC Machining(cnc cutting tools Miles)

CNC machining is a manufacturing process known for its precision and versatility. One important aspect of this process that contributes significantly to both its functionality and finish quality is bead…