Introduction to Aluminum Parts Machining and CNC Techniques

In the manufacturing industry, the machining of aluminum parts plays a crucial role for its effortless machinability which makes it an ideal choice for delivering high-quality products with an exceptional degree of precision. The lightweight yet strong nature of aluminum brings forth numerous possibilities in the world of production. Progressively important in this process is Computer Numerical Control (CNC) techniques.

- CNC milling and turning machines significantly boost efficiency by running advanced programs using CAD/CAM files, enabling manufacturers to produce complex designs faster and more precisely.

- The application of CNC devices decrease cycle times, optimize material usage, lowers production cost and improves product quality.

- Furthermore, these programmable machines can perform multiple operations concurrently without manual intervention thus minimizing any possibility of human errors.

Suffice to say that CNC techniques carve out a path to achieve increased efficacy while reducing waste in the manufacturing sector, up-levelling competitiveness amongst the industries.

Understanding Aluminum Parts Machining

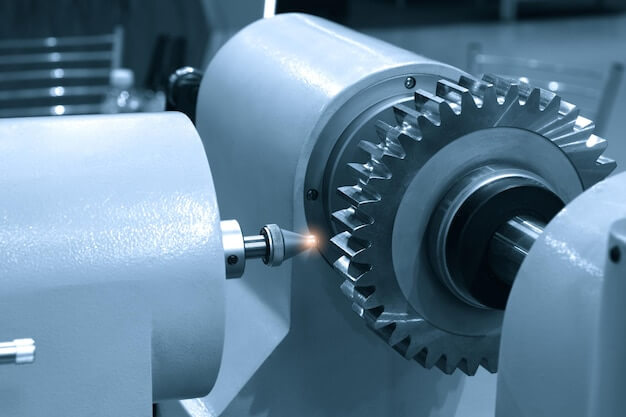

Aluminum parts machining is a precise manufacturing process that transforms aluminum material into specialized parts. This operation typically involves computer numerical control (CNC) machines to ensure precision and efficiency. The CNC machine works by following programmed instructions to manipulate the raw aluminum, conducting exact cuts, drills, and forms to create the demanded part.

In simple terms, think of this process like sculpting from a block of clay—only with aluminum and technology! These CNC machines swiftly slice away sections of the aluminum until they reveal the needed shape—a procedure known as subtractive manufacturing. To illustrate, if an engine requires a specific lightweight yet durable gear, aluminum would be ideal due to its high strength-to-weight ratio. A design for this gear is inputted into the CNC system, where it instructs the machine to carve out the detailed specifications accurately from an aluminum block, resulting in a sturdy, perfectly formed component.

Role of CNC Techniques in Precision and Efficiency:

- Advanced Machining: CNC techniques play a crucial role in achieving precision and efficiency in aluminum parts machining. The use of computer-controlled machines ensures accurate and consistent production of complex aluminum components.

- Service Provider: When seeking precision and efficiency in aluminum parts machining, it is essential to partner with a reliable Precision Machining Service that offers expertise in CNC techniques and proven capabilities in aluminum parts fabrication.

Advantages of Using CNC Techniques for Aluminum Parts Machining

The utilization of CNC techniques in machining aluminum parts offers a myriad of advantages, particularly concerning productivity, waste reduction and consistency. CNC machines possess the capacity to operate round-the-clock without interruptions, providing an enormous boost to productivity rates. Moreover, this 24/7 operation capability is less labor-dependent as a single machinist can supervise multiple CNC machines, thereby reducing operational costs.

- CNC programs are designed to maximize material usage leading to a significant decrease in wastages – a feature that’s not only cost-effective but also eco-friendly.

- Advanced precision accompanied by repeatability is another key benefit offered by these sophisticated tools. It implies when identical components need to be mass-produced, every single part will carry the exact same specifications, ensuring consistent output quality each time.

Overall, with supreme accuracy and speed paired with minimal wastage, the adoption of CNC techniques evidently underpins more efficient and profitable manufacturing processes.

Limitations and Solutions of CNC Techniques in Aluminum Parts Machining

While the implementation of CNC techniques has brought great precision and efficiency to aluminum parts machining, certain challenges persist. One notable limitation is the heat generated during the machining process, which may lead to dimensional inaccuracies in the final product. To alleviate this issue, operators could employ coolants or optimize the feed rates for better heat management. Another concern is the high initial investment on CNC machines and their maintenance needs, a cost burden particularly for small enterprises. A practical solution would be implementing co-sharing manufacturing facilities, allowing companies to share resources, thus cutting costs. Additionally, programming complexities linked to developing specific tools can result in production delays. Offering comprehensive training programs for machinists and investing in user-friendly software can help overcome these complications.

- Possible challenge: Excessive heat generation leading to inaccuracies.

- Solution: Use of coolants and optimization of feed rates.

- Possible challenge: High initial and maintenance costs of CNC machines.

- Solution: Implementation of co-sharing manufacturing facilities.

- Possible challenge: Programming complexities causing production delays.

- Solution: Comprehensive training programs and user-friendly software.

Conclusion

In summary, the precision and efficiency offered by CNC techniques in machining aluminum parts are remarkable. Throughout this article, we’ve delved into understanding how CNC technology facilitates precise drilling, shaping, turning and milling of aluminum, creating high-quality components for a wide variety of applications. These methods like close tolerance machining and use of CAD/CAM systems provide an unprecedented level of accuracy and consistency.

- The application of advanced cutting tools which can withstand high heat and pressure has revolutionized this process as well.

- Anodizing after machining offers excellent surface finishing, making the products more durable and aesthetically pleasing.

- We also unpacked principles such as ‘Chip Thinning’, significant in maintaining tool longevity and leanness of operation.

This is integral to various everyday items around us – from transport machinery to kitchen wares, electronic gadgets to aerospace parts, all bearing testimony to this process’s wonder. The undeniable impact these techniques have on product quality and life-cycle should indeed be appreciated by users and manufacturers alike.

Other Articles You Might Enjoy

- Tool Steel Grades in CNC Machining: Which One Should You Choose for Durability?

Introduction to Tool Steel in CNC Machining In the realm of CNC (Computer Numerical Control) machining, tool steel reigns supreme due to its exceptional durability and versatility. As a broad…

- Innovative CNC Machining for Custom Medical Instruments

Innovative CNC Machining for Custom Medical Instruments Computer Numeric Control (CNC) machining is an innovative automated process that utilizes computer software to control machine tools. The use of CNC machines…

- Tool Steel Grades in CNC Machining: Which One Should You Choose for Durability?

Introduction to Tool Steel in CNC Machining In the realm of CNC (Computer Numerical Control) machining, tool steel reigns supreme due to its exceptional durability and versatility. As a broad…