Introduction to Laser Cutting Technology

Laser cutting is a precise method of slicing materials using a high-powered laser beam, characterized by its ability to produce clean cuts with smooth edges on a variety of substances including metal, plastic, glass, and wood. This paragraph sets the stage for an in-depth exploration into the sophistication behind laser cutting processes, the numerous advantages it offers over traditional machining methods, as well as its diverse applications across industries from manufacturing to design. The forthcoming sections will elucidate the technical underpinnings, dissect the components that make up a standard laser cutting system, and highlight practical examples illustrating the expansive utility of this cutting-edge technology.

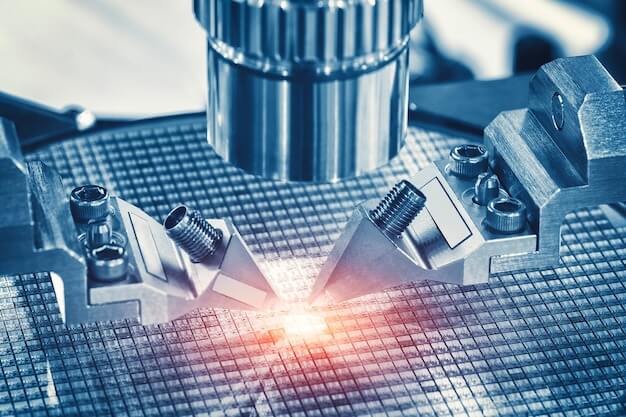

Understanding Laser Cutting Technology

Laser cutting is a precise method of slicing materials by directing a high-power laser through optics. The process utilizes a focused laser beam to melt, burn, or vaporize the material with exceptional precision and control. As lasers operate by amplifying light, different types are chosen based on their wavelengths and suitability for the material at hand—a CO2 laser, for example, is ideal for organic materials like wood and plastic, whereas fiber and crystal lasers excel in dealing with metals due to better energy absorption characteristics. Computer-assisted programming plays an integral part, allowing intricate designs to be cut with speed and repeatability. With instructions uploaded to a controlling computer, the laser’s path is meticulously guided over the material to fabricate components with complex geometries that would be difficult to achieve using traditional machining processes.

Advantages of Laser Cutting

Laser cutting stands out for its precision and accuracy, enabling intricate cuts with sharp details that traditional methods struggle to achieve. The technology’s versatility is evident as it smoothly transitions between different materials such as metals, plastics, glass, and composites without the need for tool changes. This adaptability enhances productivity by minimizing setup time, leading to greater speed and efficiency in processing tasks. Additionally, laser cutting promotes sustainability through low waste generation, as the process concentrates energy precisely where needed, thereby reducing excess scrap material. Furthermore, the contactless nature of laser cutting means there is minimal heat damage to surrounding areas of the workpiece, which preserves the integrity of the material and eliminates additional finishing steps often required when using conventional cutting techniques.

Applications of Laser Cutting Across Industries

Laser cutting is pivotal in manufacturing for fashioning intricate parts and components with precision, playing a fundamental role in the prototyping phase by facilitating rapid design validation. In the realms of fashion and textiles, it revolutionizes pattern cutting, allowing for intricate designs and speedy production cycles that traditional methods cannot match. The art community notably benefits from this technology; laser cutters transform various materials into detailed sculptures and installations that would otherwise require painstaking manual effort. By streamlining the creative process, laser cutting enables artists to realize complex concepts, pushing the boundaries of what can be achieved through conventional artistic methodologies.

Innovations and Future Development in Laser Cutting Technology

As laser cutting technology gallops into the future, innovations in laser power and control are pushing the boundaries of what’s possible. Enhanced precision and increased efficiency characterize current advancements, with developers focusing on higher-powered lasers coupled with sophisticated control systems that tailor the beam’s attributes for optimized cutting performance on various materials. The trend pivots towards integrating artificial intelligence to automate and refine the process further. In conjecture with other technological strides, such as advanced robotics and IoT, laser cutting’s potential applications could widen – from smart manufacturing processes to complex medical surgeries. These integrative advancements hint at a transformative horizon for laser cutting, where its synergy with emergent tech paves the way for revolutionary uses across multiple industries.

Challenges and Considerations in Laser Cutting

Laser cutting, while versatile, poses several challenges and necessitates meticulous considerations to ensure safety, efficiency, and cost-effectiveness. One significant limitation is the material compatibility; not all substances can be effectively cut with a laser, as some may reflect the beam, absorb heat excessively, or emit hazardous fumes upon vaporization. Materials such as PVC or materials with high reflective properties are typically avoided in laser cutting operations to prevent equipment damage or health hazards. Safety is another crucial aspect, requiring operators to adopt rigorous precautions like wearing protective eyewear to shield against harmful laser radiation and implementing robust exhaust systems to evacuate fumes from the cutting area. Furthermore, the initial investment for a state-of-the-art laser cutting system can be substantial, and so does the ongoing maintenance required to keep the apparatus functioning optimally. Operators must consider these expenses along with the routine replacement of components, such as lenses and nozzles, which suffer wear over time and affect the precision of cuts.

Materials and Capabilities of Laser Cutters

Laser cutters are versatile tools capable of processing various materials, including metals such as steel and aluminum, plastics like acrylic and polycarbonate, wood, glass, paper, and textiles. They can precisely slice through different thicknesses, often up to 20-25 mm for metals and even thicker for softer materials, though the specific limit depends on the laser’s power rating. With environmental impact in mind, laser cutting is more eco-friendly compared to traditional methods due to its high efficiency and precision which reduces waste. Moreover, these machines can also engrave with detailed results, adding functionality beyond mere cutting. Designing for laser cutting requires attention to detail; common mistakes involve ignoring kerf size—the material removed during cutting—which affects the exactness of fit for parts or overly intricate designs that may not be well-supported or could burn excessively.

Other Articles You Might Enjoy

- CNC Cutting vs. Laser Cutting: Which Manufacturing Process is Right for You?

In the manufacturing industry, there are two commonly used methods for precision part production: CNC cutting and laser cutting. Both methods offer unique advantages and play a crucial role in…

- Beyond Cutting: Exploring the Multifaceted CNC Machining Process

1. Introduction: Unveiling the Layers of CNC Machining In this introductory section, we peel back the layers of the CNC machining process, going beyond the traditional understanding of cutting. It…

- Exploring Laser Cutting: Techniques, Advantages, and Sectors

Introduction to Laser Cutting Technology Laser cutting represents a precision technology where a high-powered laser is directed at material to cut or etch designs as dictated by computer-controlled parameters. This…