CNC Machining and Material Efficiency: Aluminum 2024 vs. 6061 vs. 7075

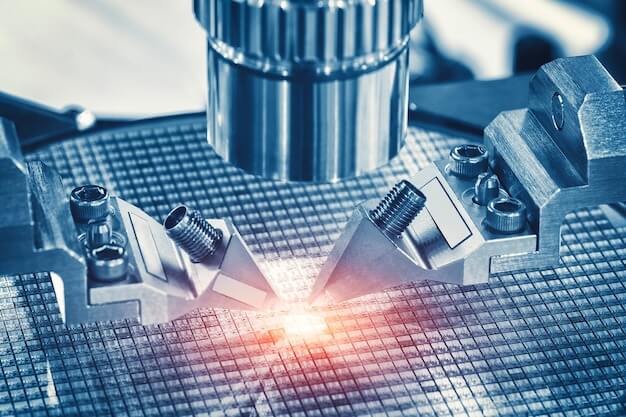

CNC machining refers to a highly automated process widely employed in the manufacturing sector, using computer numerical control (CNC) to dictate the movements of machinery tools. This method allows for greater control and precision in manufacturing many different kinds of materials, including aluminum. The efficiency of this manufacturing technique can vary depending on the material used, prompting comparisons between various types of aluminum – namely Aluminum 2024, 6061, and 7075. Each of these alloys are distinguished by key characteristics regarding their strength, weight, thermal conductivity, corrosion resistance, and weldability, all directly affecting their material efficiency when worked with CNC machines. In subsequent sections, we will delve into specifics about the comparative strengths and weaknesses of each type of aluminum.

Understanding Material Efficiency

Material efficiency, in the most basic sense, refers to the optimal utilization of materials while minimizing waste during manufacturing processes. It’s a vital performance metric evaluated throughout industry sectors and is especially crucial in the field of CNC machining. The primary goal of achieving high material efficiency is to extract the maximum possible value from each piece of material used while generating the least amount of waste.

In the context of the manufacturing industry, material efficiency takes on heightened importance due to multiple reasons. A fundamental reason lies in its direct contribution to cost optimization – higher material efficiency translates directly into lower production costs per unit as fewer raw materials are required for producing yhe same number output units. Similarly, efficient use of materials reduces scrap generation, contributing to cleaner, more sustainable operations by reducing the environmental footprint of the business.

To illustrate, consider an aluminum rod undergoing a CNC machining process say, drilling or cutting. An operation with poor material efficiency might result in excessive metal chips being produced as waste. In contrast, a highly material-efficient process would minimize such wastage, yielding more finished products per unit of raw material, thus boosting profitability and promoting sustainability.

Aluminum as a Common Material for CNC Manufacturing

Aluminum, particularly types 2024, 6061, and 7075, is widely used in Computer Numerical Control (CNC) manufacturing due to its distinctive properties. It is light yet strong with excellent machining capabilities, making it ideal for producing components such as enclosures or brackets.

- 2024 Aluminum: Also known as ‘aircraft alloy’, it maintains good strength and hardness even at high temperatures. However, it isn’t weldable and has poor corrosion resistance, mainly used in applications where high strength-to-weight ratio is critical i.e., gears and fasteners.

- 6061 Aluminum: This type excels in weldability and corrosion resistance which makes it suitable for building yacht construction and automotive parts.

- 7075 Aluminum: The strongest of these alloys, often used when strength is the most crucial factor, like aerospace industry parts.

The classification of aluminum significantly impacts manufacture performance and end products; therefore, choosing the right kind is essential depending on the product’s intended use.

Deep Dive into the Characteristics of Aluminium 2024

Aluminium 2024 is a widely used alloy known for its excellent strength-to-weight ratio and fatigue resistance. Here is a step-by-step description of its characteristics:

1. Chemical Composition:

- Aluminium 2024 is composed of approximately 90% aluminium (Al), 4.4% copper (Cu), 1.5% magnesium (Mg), and 0.6% manganese (Mn).

- It also contains small amounts of other elements such as iron (Fe), silicon (Si), and zinc (Zn).

2. Strength and Weight:

- Aluminium 2024 offers high strength, comparable to some steel alloys, while being significantly lighter in weight.

- Its strength-to-weight ratio makes it suitable for applications where weight reduction is critical, such as aerospace and automotive industries.

3. Fatigue Resistance:

- Aluminium 2024 exhibits excellent fatigue resistance, making it suitable for applications subjected to cyclic loading and stress.

- It can withstand repeated stress without experiencing fatigue failure, making it ideal for structural components.

4. Corrosion Resistance:

- While Aluminium 2024 offers good corrosion resistance, it is not as corrosion-resistant as some other aluminium alloys.

- It is susceptible to corrosion in certain environments, particularly in the presence of moisture and chloride ions.

5. Machinability:

- Aluminium 2024 has good machinability, allowing for efficient and precise machining operations.

- It can be easily formed, drilled, cut, and shaped, making it suitable for various manufacturing processes.

By understanding the characteristics of Aluminium 2024, manufacturers can make informed decisions when selecting materials for CNC machining projects. To explore CNC machining services that offer expertise in working with Aluminium 2024, you can visit our online CNC service.

Reviewing Aluminum 6061

The distinct qualities of aluminium 6061 make it a popular choice in various industries due to critical characteristics such as corrosion resistance. Unlike some other alloys, aluminum 6061 offers excellent resistance to corrosive environments, making it ideal for applications where durability and longevity are paramount. This feature is essential in many industrial settings where materials are exposed to harsh elements or conditions.

- Corrosion Resistance: One of the primary factors that separate Aluminium 6061 from many other metals is its ability to resist corrosion. It retains its structural integrity even when exposed to moisture, saltwater, and chemicals which makes it suitable for use in a variety of high-exposure environments.

- Application: Given this characteristic, examples of uses for aluminum 6061 can be found in diverse areas ranging from the construction industry—where it’s used in building infrastructures resistant to weather degradation—to the aerospace industry, where it helps ensure optimal performance of aircraft components exposed to varied atmospheric conditions.

Spotlight on Aluminium 7075

The aluminum alloy 7075 is recognized for its superior stress-corrosion cracking resistance which makes it an ideal choice in many sectors. This attribute, coupled with its high strength and weight ratio, renders aluminium 7075 as a preferred material to work with over other alloys. For instance, in the aerospace industry where reliability under excessive strain is paramount, this material’s resistance to stress improves aircraft parts durability. Similarly, in the automotive sector, its corrosion resistance translates into prolonged life of components exposed to varying weather conditions and corrosive substances like road salts.

Comparative Analysis: Aluminum 2024 vs. 6061 vs. 7075

In comparing the three types of aluminum alloys, 2024, 6061, and 7075, several similarities and differences arise in their essential properties i.e., weight and strength. Aluminum 2024 is known for high strength-to-weight ratio and good fatigue resistance but it does lack corrosion resistance compared to other alloys. On the other hand, Aluminum 6061 presents a higher level of corrosion resistance, ease of machining, and an overall balanced mixture of properties- weight, strength, and weldability- which makes it commonly used in many applications.

- Weight: All three exhibit light weight characteristic inherent to Aluminum though slight variations arise based on alloying elements.

- Strength: 2024 exhibits superior strength while 6061 offers adequacy; however, 7075 markedly provides highest yield strength among them.

- Corrosion Resistance: Comparatively, 6061 surpasses the rest in this domain due to addition of silicon and magnesium, providing better anodized film.

Conclusively, choice depends entirely on specific applications – aluminum 2024 excels in applications requiring good fatigue resistance like aircraft structures; 6061 shines where excellent welding characteristics, good corrosion resistance are needed such as in piping,furniture construction; whereas 7075 is preferred where maximum strength is required, for instance, in gears and shafts.

Conclusion

In conclusion, Aluminum 2024, 6061, and 7075 are each beneficial in their own right for various applications based on individual project requirements. Aluminum 2024 is celebrated for its high strength-to-weight ratio and superior fatigue resistance, ideally suited for applications such as aircraft structures. Conversely, the corrosion-resistant nature of Aluminum 6061 along with its weldability renders it best suitable for machining purposes or structural components across industries. The last variant, Aluminum 7075, reciprocates an exceptional testament to strength and toughness and finds its usage predominantly in highly stressed parts. Each version exhibits distinctive features relating to machinability, formability, susceptibility to heat treatment etc. Deciding upon a fitting aluminum type requires careful consideration of these unique properties aligning directly with the desired use-case scenario.

Other Articles You Might Enjoy

- The Role of Precision in CNC Machining: How Tight Tolerances Impact Cost and Quality?

Introduction: Understanding Precision in CNC Machining In manufacturing contexts, precision is epitomized by Computer Numerical Control (CNC) machining. In essence, CNC machining is a process utilized widely within the manufacturing…

- The Advantages of Using LSR (Liquid Silicone Rubber) in CNC Prototyping and Production?

Introduction to LSR in CNC Prototyping and Production The utilization of Liquid Silicone Rubber (LSR) in CNC prototyping and production has been growing exponentially due to its numerous advantages. For…

- Aluminum CNC Machining Part Production for Custom Solutions

Introduction to Aluminum CNC Machining Part Production CNC (Computer Numerical Control) machining is a subtractive manufacturing technology whereby computer software directs the movement of factory machinery and tools, ensuring precision…