Bead blasting, an essential process within the realm of Computer Numerical Control (CNC) machining, has revolutionized the manufacturing industry. Industry professionals worldwide regard it as a critical finishing operation for lending superior quality to machine-created products.

Understanding Bead Blasting

Considered a type of abrasive blasting, bead blasting refers to the method where tiny glass beads are blown onto a surface by pressurized air to give it a clean, bright, and satin-like finish. This procedure doesn’t damage or alter the dimensions of the component, instead, removes surface deposits only.

Application of Bead Blasting in CNC Machining

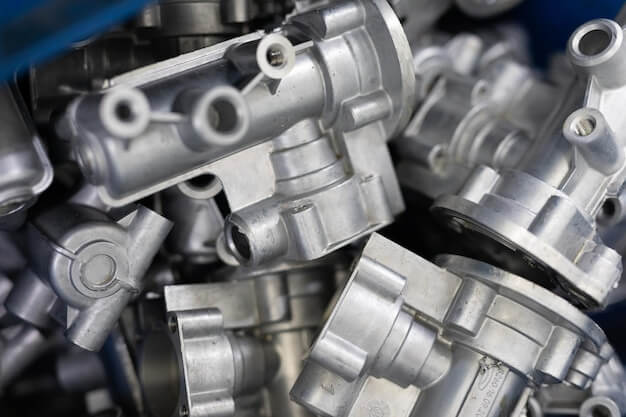

In the world of CNC machining, bead blasting is commonly used as a surface finishing technique. The process finds extensive application in removing machine lines on aluminum parts, cleaning mild discrepancies on surfaces, and generating uniformly smooth finishes on 3D printed prototypes or machined components.

Besides rendering aesthetic improvements, bead blasting augments the longevity of the machines. It assists in eliminating burrs – minuscule pieces of material causing potential hazards, which may impact performance over time. Furthermore, through combating corrosion and improving lubrication, bead blasting helps reduce maintenance costs while enhancing the machinery’s functional lifespan.

Detailed Process of Bead Blasting

The bead blasting process encompasses multiple stages, each demanding meticulous precision:

1. Preparation: Initially, operators remove loose dirt and oil from parts, cutting down contaminants that might safeguard the underlying surface during blasting.

2. Blasting: Simultaneously propelled by high-speed compressed air, small spherical beads impact the surface intensely. Depending on the desired output, variations can be made by adjusting factors like bead size, blast pressure, and angle of attack.

3. Post-blasting: Finally, after jet-propelled beads cleanse the surface, a post-blast rinse eliminates residual blast media ensuring an impeccably clean end product.

4. Inspection: For delivering consistent results, operators usually conduct a final inspection to verify the bead blasting process’s effectiveness.

Striking Benefits of Bead Blasting In CNC Machining

Bead blasting offers multiple attractive advantages that make it highly favored in CNC machining:

Aesthetic Appeal: It adds an attractive aesthetic touch to finished products owing to its ability to provide both uniformly rough and satin finishes based on varying requirements.

Versatile Application: From automotive parts to medical equipment, cooking utensils to aerospace components, bead blasting is versatile enough for use across different industry segments due to its non-destructive nature.

Durability Enhancement: By impeding corrosion buildup, reducing sharp edges that may cause tears or cracks, and improving general lubrication, this method promotes component durability.

To Conclude

Integral to CNC machining, bead blasting plays a significant role in ensuring quality standards of finished industrial components. Not only does it elevate visual appeal but also contributes to functionality and longevity. This cost-effective solution has truly ushered in a wave of efficiency and accuracy within the broader manufacturing sphere, underlining why mastering it can be pivotal for success in CNC machining endeavors.

Other Articles You Might Enjoy

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…

- Nickel vs. Cobalt Alloys in High-Temperature CNC Machining: A Detailed Analysis?

Nickel and Cobalt Alloys in High-Temperature CNC Machining Both Nickel and Cobalt alloys play an essential role in high-temperature CNC machining. These metal alloys are popular choices due to their…