CNC turning is a crucial method used in the manufacturing industry. Understanding this process, along with recognizing different types of rivets, can provide profound insight into the operative principles behind numerous products around us.

Let’s start with an introduction to CNC turning. In essence, Computer Numerical Control (CNC) turning is one more connection in the endless chain of technological advancements. It offers manufacturers precision and efficiency that was unimaginable just a few decades ago. This technique comprises programmed computer controls operating lathes equipped for automated production—ones responsive to even the slightest commands, providing meticulous results every time.

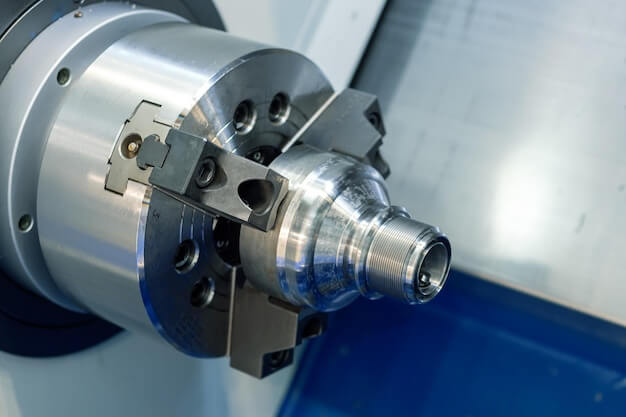

If you’ve seen cylindrical or rotationally symmetrical objects like screws, musical instruments, wheels—they’re made using the process of turning via allowing material removal from workpieces efficiently and accurately. The procedure involves securing raw material on a chuck—a specialized clamp—and rotating it while cutting tools shave off excess layers until the desired shape emerges.

With CNC turning machines, however, things take an even more interesting turn. These high-tech devices eliminate manual intervention thanks to pre-programmed software guiding their activity. Thus, accuracy skyrockets—all the way to 0.01 mm. Further enhancing speed and reducing production costs are among other advantages. Additionally, these machines have impressive versatility—they can work with a multitude of materials ranging from metals, plastic, wood right through to glass.

In terms of production, it’s fairly straightforward if somewhat cost-intensive initially. Firstly, suitable design software is essential. Once armed with your digital blueprint, you need to translate it into a language for your CNC machine—it’s called G-code—a series of instructions interpreting your design’s parameters. After checking everything twice—the codes, tool settings, fixtures—you mount your workpiece and let the magic unfold as splendidly intricate shapes emerge seamlessly.

Onwards to another unsung hero of manufacturing—rivets. A hallmark of robust construction, rivets are permanent mechanical fasteners that join objects together. Despite their low profile, the sheer variety of rivets might astonish you!

Primarily, there are five types of rivets—solid rivets, semi-tubular rivets, blind rivets, drive rivets, and flush rivets.

The solid rivet commands most of its historical popularity for its sturdiness. It functions by pushing a punch or riveting hammer onto its uncovered part until it expands to about 1.5 times the original shaft diameter, creating a “shop head” which binds materials unrestrictedly together.

Semi-tubular rivets take this one step further with adept material usage: its end is partially hollow, reducing the amount needed to form the head. This clever design tweak ensures less force while installation without compromising on strength.

Blind rivets, also known as ‘pop’ rivets, revolutionize accessibility by making possible what seemed impossible earlier — attaching pieces when you can only reach one side. Using a purpose-built tool, it breaks or pops out after installing, lending them their alternative name.

Drive rivets, much like hammers within fastening world, need just a strike to set them in place—they’re perfect for quick assembly.

Last but not least, flush rivets present an innovative solution ensuring a smooth finishing surface due to their flat heads. Predominantly used in aerodynamics where every protrusion counts, these clever contraptions make aircraft smoother hence faster.

Summarizing, exploration into CNC turning through production stages and navigating various kinds of rivets may seem esoteric at first glance. Still, delve deeper, and they shape the industrial landscape around us more than we realize. Knowing how things are made empowers us in countless ways—from smarter purchase decisions to recognizing quality—it’s worth delving into our engineered environment head first!

Other Articles You Might Enjoy

- The Impact of Material Selection on CNC Machining Speed and Quality

Introduction to CNC Machining CNC machining stands as a cornerstone in modern manufacturing, utilizing computer numerical control to operate machine tools with high precision. This process is pivotal for creating…

- Ceramics in CNC Machining: A Viable Alternative to Traditional Metals?

CNC Machining and Its Importance in Manufacturing Computer Numerical Control (CNC) machining stands as a critical pillar within the sphere of manufacturing, lauded for its accurate and fast production capabilities.…

- CNC Turning: A Deep Dive into Rivet Production(cnc laser cutting Adolph)

Introduction:Computer numerical control (CNC) represents one of the most crucial inventions in manufacturing technology. It pertains to a method used to control an array of complex machinery using computer programs…