Introduction to 5-Axis CNC Machining

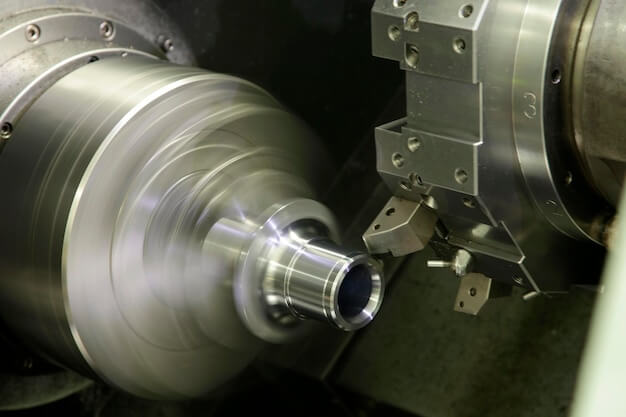

Cementing itself on the technological forefront, computer numerical control (CNC) machining is a manufacturing process that utilizes computerized controls to manoeuvre factory machines and tools. Widening its capabilities beyond traditional 3-axis systems is the revolutionary 5-axis CNC machine. Unlike its predecessor which could only operate in three planes (X, Y, Z), the 5-axis system has two additional pivot points allowing for not just side-to-side and up-and-down movements, but also rotations.

In layman’s terms, imagine you’re sculpting an object from a block of material. With a basic 3-axis tool, reaching every angle can be challenging as your freedom of motion is limited. However, with a 5-axis setup, your carving tool practically mirrors the dexterity of a human hand, adeptly maneuvering around the object, rotating and pivoting freely. This opens doors for complex operations including cutting or drilling from multiple angles, curving intricate designs, and even creating hollow spaces within parts – all leading to faster completion times, enhanced precision and improved efficiency.

Importance of Steel as a Material

In the realm of manufacturing, steel emerges as an indispensable material due to its extensive utility and inherent properties. Its widespread use spans various industries, ranging from automotive and aerospace to construction and consumer goods. Primarily responsible for making steel ideal is its unique blend of mechanical properties such as high tensile strength, ductility, malleability, durability and thermal resistance.

- High Tensile Strength: Steel can withstand great amounts of load without breaking or deforming, thus making it suitable for heavy-duty applications.

- Ductility & Malleability: Ease in shaping or bending allows manufacturers to mold steel into complex parts with precision.

- Durability: Outperforming most materials in terms of lifespan, resisting wear and tear translates to reduced maintenance costs.

- Thermal Resistance: Steel’s ability to maintain structure under high temperatures proves crucial in sectors such as energy and transportation.

Therefore, the versatility, robust structural integrity, longevity, and heat-resisting qualities make steel unparalleled in efficiencies within 5-axis CNC machining processes dedicated to producing intricate and accurate components consistently.

The process of 5-axis CNC machining of steel components involves the simultaneous movement of cutting tools along five axes to achieve intricate and precise parts. This process offers increased efficiency and precision compared to conventional machining methods. By utilizing 5-axis CNC machining, manufacturers can produce complex steel components with minimal setups, saving time and cost. To achieve the desired results, it is essential to work with a online CNC service that specializes in precision machining and has expertise in 5-axis CNC machining of steel components.

Efficiency of 5-Axis CNC Machining

The 5-axis CNC machining offers a higher level of efficiency compared to traditional methods. This enhanced efficiency is due to its ability to perform multiple operations in one setup, reducing the time it takes for part handling and set-up changes, thereby increasing productivity. In contrast with conventional 3-axis machines, where components need to be manually repositioned for various cuts, 5-axis machines cut all five sides in a single operation, significantly optimizing workflow.

To illustrate this efficiency, consider an analogy of cutting a cube-shaped component. While a traditional method might require six different setups – one for each side of the cube – the 5-axis CNC machine can accomplish the same task in just two setups: one for the first four sides and another for the last two sides. This straightforward example highlights how the use of 5-axis CNC machining lends itself to rapid production times, minimizing manual intervention and enhancing precision without sacrificing quality.

Precision in 5-Axis CNC Machining

The precision inherent in 5-axis CNC machining is primarily derived from its unique ability to move a tool or a part on five different axes simultaneously. This multi-dimensional movement allows intricate detailing that would otherwise be impossible with less sophisticated equipment. Imagine carving a perfect sphere out of a block of steel. With traditional equipment, this process would typically require several stages and manual adjustments, increasing the likelihood of human error. However, with 5-axis milling, the machine makes precise movements along the X, Y, Z (linear) as well as A and B (rotational) axes to carve out the entire shape seamlessly – all at once. The unmatched level of control translates into superior accuracy, delivering finished components with incredibly tight tolerances down to +/-0.001 inches. Hence, the capability to handle complex geometries without sacrificing precision places 5-axis CNC machines as an indispensable asset in various manufacturing environments.

Common Challenges Faced in 5-Axis CNC Machining

In the realm of 5-Axis CNC machining, operators often encounter a multitude of challenges that can impact efficiency and precision. One common issue is dimensional instability which arises due to variations in temperature or workpiece material inconsistency. A practical solution would be to implement thermal compensation techniques, in addition to choosing materials with low coefficient of thermal expansion.

Another notable difficulty involves tool-paths programming, especially for complex shapes. Given the increased degrees of freedom in 5-axis CNC systems compared to their 3-axis counterparts, generating error-free and efficient tool paths becomes significantly more complicated. In such instances, utilizing advanced CAM software equipped with robust algorithms could help mitigate this problem.

Machinists also face risks of costly collisions between machine elements during simultaneous movements. Simulation-based verification methods are suggested as these allow operators to detect any potential collision before actual production commences, thereby reducing downtime and preventing structural damage to the machinery. Lastly, maintaining the accuracy over prolonged periods of operation under heavy-duty cycles can also pose an operational challenge.To maintain optimal operation, scheduled maintenance activities need to be strictly adhered to, ensuring the tools remain sharp and bearings, guides or spindles don’t wear out prematurely. Indeed, overcoming these obstacles requires not only technical understanding but meticulous planning and preventive protocol adherence.

Conclusion

The 5-Axis CNC machining process has been highlighted as an efficient, precise method for crafting steel components – a game-changer in today’s manufacturing world. We observed this technology’s ability to produce complex structures with fewer setups, reducing production time while maintaining high level precision. Alongside this, the improved surface finish quality and comprehensive tool movement it offers cement its status as an indispensable element in modern fabrication processes.

- The utilization of tool paths unique to full simultaneous 5-axis machining decreases cycle times whilst enhancing part accuracy.

- In addition to unmatched efficiency, effectiveness, and versatility, 5-Axis CNC machines reduce human error and deliver consistent results.

Taking these factors into account, it is clear that 5-Axis CNC machining stands at the forefront of advancement in manufacturing industries: An innovative solution providing streamlined operations and superior results. Given how critical precision and efficiency are to meet customer expectations and keep pace with market demands, any manufacturer aiming to stay on top must embrace this cutting-edge technology.

Other Articles You Might Enjoy

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…

- Nickel vs. Cobalt Alloys in High-Temperature CNC Machining: A Detailed Analysis?

Nickel and Cobalt Alloys in High-Temperature CNC Machining Both Nickel and Cobalt alloys play an essential role in high-temperature CNC machining. These metal alloys are popular choices due to their…