Introduction

As a machinist who’s spent years honing my craft in CNC machining, I’ve learned that shear force is the heartbeat of every precise cut. It’s the invisible force that transforms raw materials into intricate components, and mastering it is what elevates CNC machining from routine to remarkable. In this guide, I’ll share insights from my shop floor experience, blending technical know-how with practical strategies to optimize shear force, ensuring top-tier part quality, minimal tool wear, and robust machine performance in CNC machining.

What is Shear Force in CNC Machining?

In CNC machining, shear force is the driving force behind material removal. It’s the push from the cutting tool, acting parallel to the cutting plane, that forces the material to deform and form a chip. I’ve watched this process countless times—when shear force surpasses a material’s strength, it shears along a plane defined by the shear angle (φ). A larger shear angle shortens the shear plane, reducing the shear force needed. This translates to less power, cooler cuts, and smoother CNC machining operations. From my perspective, tweaking this angle is like tuning an engine for peak efficiency in CNC machining.

Shear Force vs. Shear Stress

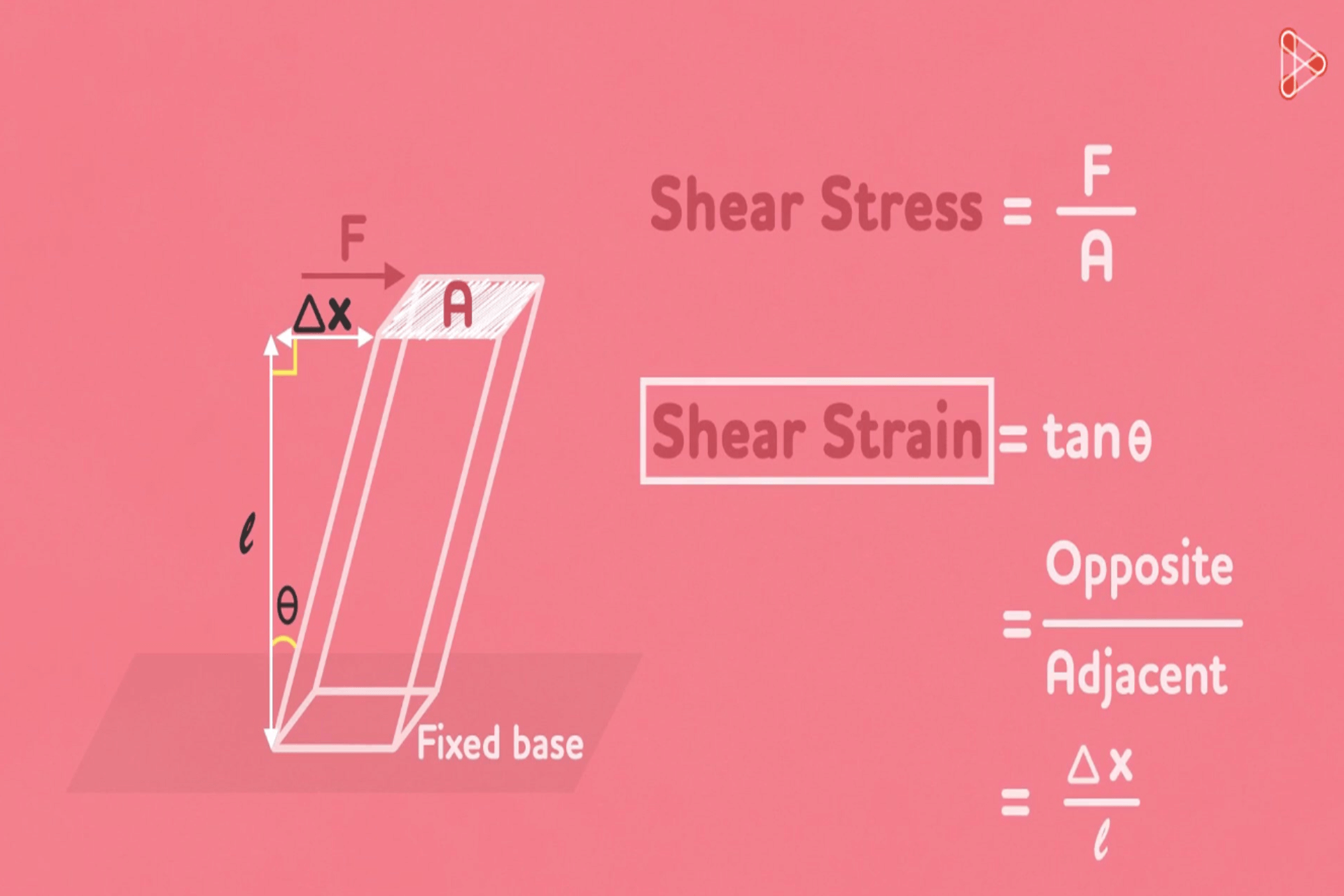

- Shear Force (F): Measured in Newtons (N), it’s the total force the tool applies to carve out material in CNC machining.

- Shear Stress (τ): Calculated as τ = F/A (force per unit area), this is the material’s internal resistance, measured in Pascals (Pa), that ultimately yields under pressure.

In my experience, understanding the distinction helps troubleshoot issues like excessive tool wear or poor finishes in CNC machining. Monitoring shear force gives me a direct sense of the load on my machine, while shear stress clues me into how the material is fighting back.

The Ecosystem of Cutting Forces

Shear force doesn’t work alone in CNC machining. It’s part of a trio:

- Cutting Force (Fc): Drives the tool’s motion, dictating power needs.

- Thrust Force (Ft): Pushes perpendicularly, often causing tool deflection.

I rely on the Merchant Circle Diagram to visualize these forces. Early in my career, I used it to calculate shear force when setting up new jobs, ensuring my CNC machining setup was optimized for minimal strain and maximum precision.

The Workpiece Material: The Core of Shear Force Challenges

The material you’re cutting in CNC machining sets the stage for shear force. I’ve machined everything from buttery aluminum to stubborn Inconel, and each material tells a different story. Hardness, ductility, thermal conductivity, and strain hardening all shape the shear force required. Here’s a breakdown based on my hands-on work:

| Material | ISO Group | Machinability Rating (%) | Key Properties | Chip Formation | Shear Force Impact in CNC Machining |

| 6061-T6 Aluminum | N | 90–450% | Low hardness, high thermal conductivity , ductile | Long, curly chips | Low shear force , but sticky chips can clog. Sharp tools and coolant are my go-to. |

| 1018 Mild Steel | P | ~78% | Moderate hardness, ductile | Long, smooth chips | Moderate shear force , forgiving to machine. A staple for reliable CNC machining . |

| 4140 Alloy Steel | P | ~66% | Higher hardness, strong | Tough, continuous chips | Higher shear force , demands rigid setups. I use slower speeds for control. |

| 304/316 Stainless Steel | M | 40–45% | Work-hardening, low thermal conductivity | Stringy, tough chips | High shear force , generates heat. High-pressure coolant is a lifesaver in CNC machining . |

| Ti-6Al-4V Titanium | S | 20–35% | Low thermal conductivity , high strength | Segmented chips | Very high shear force , runs hot. I lean on low speeds and heavy coolant. |

| Inconel 718 | S | 12–16% | Extreme work-hardening, high-temp strength | Abrasive, segmented chips | Extreme shear force , brutal on tools. Patience and robust setups are key in CNC machining . |

One memorable job involved CNC machining titanium for aerospace parts. The shear force was so intense that without high-pressure coolant, my tools burned out fast. That taught me to respect material properties and plan accordingly.

The Cutting Tool: Your Shear Force Ally

In CNC machining, the tool is your weapon against shear force. A sharp tool with a positive rake angle cuts with less shear force but risks chipping. I’ve found carbide tools—three times stiffer than HSS—to be game-changers for maintaining precision under high shear force. Keeping tool overhang short is non-negotiable; I once doubled an overhang by mistake, and the deflection ruined a part. Worn tools? They spike shear force and friction, so I check edges religiously before critical CNC machining runs.

Machining Parameters: Dialing in Shear Force

Every CNC machining job hinges on three parameters:

- Depth of Cut (DOC): Deeper cuts ramp up shear force, so I balance depth with tool life.

- Feed Rate (f): Higher feeds can increase shear force but optimize shear angle for efficiency.

- Cutting Speed (v): In High-Speed Machining (HSM), faster speeds soften materials, reducing shear force. I’ve seen chips glow red-hot in HSM, carrying heat away and saving my tools.

The Ripple Effect: Shear Force Impacts

In my shop, unstable shear force is the enemy. Too much shear force causes tool deflection, leading to scrapped parts and rough finishes. I’ve heard the telltale hum of chatter from unbalanced shear force, ruining surface quality. High shear force also accelerates tool wear—I’ve replaced tools mid-job because of it—and stresses machine components, hiking power consumption. Once, a sudden shear force spike in an Inconel job snapped a tool, teaching me to respect force management in CNC machining.

Strategic Tooling: Enhancing Shear Force Control

- Tool Coatings (TiN, TiAlN): These reduce friction and heat, easing shear force. I swear by TiAlN for titanium jobs.

- High-Pressure Coolant (HPC): It’s a must for tough materials, cutting shear force and cooling the cutting zone.

- Minimum Quantity Lubrication (MQL): I use this eco-friendly option for aluminum, minimizing shear force with an oil mist.

Intelligent Toolpaths: CAM’s Role in Shear Force

Modern CAM software is a machinist’s best friend for controlling shear force. Adaptive Clearing keeps tool engagement steady, avoiding shear force spikes in corners. I’ve used Trochoidal Milling for deep slots, maintaining low shear force with smooth, circular paths. These toolpaths have saved me hours and tools in complex CNC machining projects.

High-Speed Machining: Redefining Shear Force

HSM is a revelation in CNC machining. By combining high speeds, light DOC, and fast feeds, it softens materials, slashing shear force. I’ve watched chips fly off glowing hot, carrying away heat and protecting my tools. It’s a delicate balance, but when dialed in, HSM transforms tough jobs into smooth operations.

Advanced Analysis: Precision Shear Force Management

- Dynamometers: I’ve used these to measure shear force during R&D, fine-tuning setups.

- FEA Simulations: These predict shear force and heat, saving trial-and-error costs.

- Adaptive Control Systems: These adjust feeds in real-time to stabilize shear force. On a recent job, this cut cycle time by 35%, a game-changer for CNC machining efficiency.

Micro-Machining: The Shear Force Challenge

In CNC micro-machining, small DOC increases specific cutting energy. The material gets ploughed, not sheared, spiking shear force. I’ve struggled with this on tiny features, where sharp tools and precise control are critical to manage shear force.

Conclusion: My Path to CNC Machining Excellence

From my years on the shop floor, I’ve learned that mastering shear force in CNC machining is about control, not just minimization. By understanding the shear plane, leveraging tool coatings, optimizing CAM toolpaths, and embracing HSM, I’ve turned challenging jobs into successes. Stable shear force delivers flawless parts, longer tool life, and efficient CNC machining.

FAQ:

1. What is shear force in CNC machining, and why is it important?

Shear force is the mechanical force applied by the cutting tool in CNC machining to deform and remove material, forming chips along the shear plane. From my experience, it’s critical because it determines the efficiency of material removal, impacts tool wear, and affects part quality. Managing shear force properly reduces power consumption and heat, ensuring precise, high-quality cuts in CNC machining. A well-controlled shear force can make or break a job, especially with tough materials like titanium.

2. How does shear force differ from shear stress in CNC machining?

Shear force is the total force (in Newtons) exerted by the tool to shear material, while shear stress is the material’s internal resistance per unit area (in Pascals, τ = F/A). In my shop, I think of shear force as the “push” I apply and shear stress as how the material fights back. Understanding both helps me adjust CNC machining parameters to prevent tool damage and achieve smooth cuts.

3. How can I reduce shear force in CNC machining?

Reducing shear force in CNC machining involves optimizing several factors:

- Tool Geometry: I use tools with a positive rake angle to lower shear force, though I ensure the edge isn’t too fragile.

- Cutting Parameters: Lower depth of cut and higher cutting speeds (as in HSM) reduce shear force by softening the material.

- Coolants and Coatings: High-pressure coolant and TiAlN coatings cut friction, easing shear force.

In one job, switching to adaptive clearing toolpaths slashed shear force spikes, saving my tools and improving finish.

4. What materials require the highest shear force in CNC machining?

Materials like Inconel 718 and Ti-6Al-4V demand the highest shear force due to their strength and work-hardening properties. In my experience with CNC machining Inconel, the extreme shear force and heat required robust setups and slow speeds. The article’s table highlights how these materials’ low thermal conductivity and abrasive chips amplify shear force, making high-pressure coolant essential.

5. How does shear force affect tool life in CNC machining?

High or unstable shear force increases friction and heat, accelerating tool wear. I’ve seen tools dull quickly when shear force spikes, especially in stainless steel jobs. Using CAM toolpaths like trochoidal milling keeps shear force steady, extending tool life. Regular tool inspections and coatings like TiN also help me manage shear force and protect tools in CNC machining.

6. What role does the shear angle play in CNC machining?

The shear angle defines the shear plane where material deforms. A larger shear angle shortens the shear plane, reducing shear force and improving efficiency. In my CNC machining work, I adjust feed rates and tool geometry to increase the shear angle, which cuts down heat and power use. It’s a simple tweak with big payoffs for precision and tool longevity.

7. How do CAM toolpaths help manage shear force in CNC machining?

CAM toolpaths like adaptive clearing and trochoidal milling control tool engagement, minimizing shear force spikes. I’ve used adaptive clearing on complex parts to maintain consistent shear force, avoiding chatter and tool failure. These toolpaths make CNC machining smoother and more predictable, especially for deep cuts or tough materials.

Reference

https://en.wikipedia.org/wiki/Shear_force;

https://efficientengineer.com/shear-force-and-bending-moment-diagrams/;

https://www.numberanalytics.com/blog/shear-force-essentials#google_vignette;

https://www.youtube.com/watch?v=CVno4aJjMuc;

Other Articles You Might Enjoy

- The Role of the Shear Stress Equation in CNC Process Optimization

A Personal Approach to CNC Process Optimization As someone who’s spent years working in the CNC machining field, I've come to realize that understanding the Shear Stress Equation is not…

- Why Shear Strain Matters in CNC Machining

The Importance of Shear Strain in CNC Machining Understanding shear strain is essential not only for selecting the right materials but also for optimizing machining processes in CNC applications.but also…

- How to Use Shear Stress Formula in CNC Design and Production

In the field of CNC machining, understanding mechanical properties and stresses in materials is crucial for designing parts that can withstand operational loads without failure. One of the most critical…

- Understanding the Stress Strain Curve for CNC Material Selection

The Importance of the Stress-Strain Curve in CNC Machining In the world of CNC machining, understanding the stress-strain curve isn't just a technical necessity—it's a strategic advantage. When I first…

- How Does Tensile Stress Affect CNC Machining Processes

Tensile stress is a fundamental concept in material science that has far-reaching implications in CNC machining processes. Understanding how tensile stress interacts with various materials can greatly impact the effectiveness…