About Acrylic

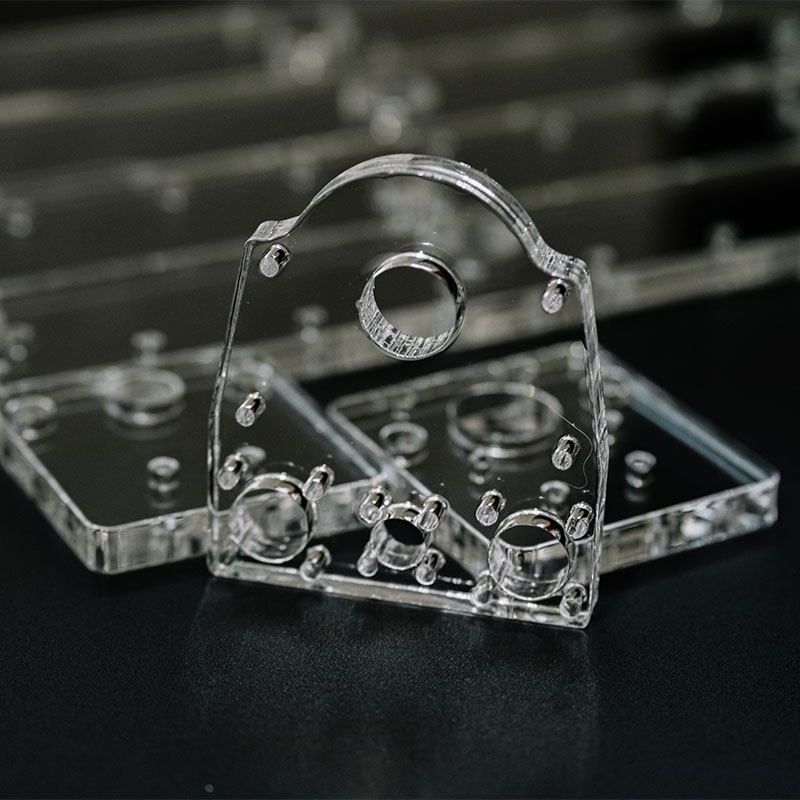

Acrylic is a popular and versatile material that is commonly used in a wide range of applications. Acrylic, also known as polymethyl methacrylate (PMMA), is a thermoplastic plastic material that is lightweight, strong, and durable. It is also known for its excellent optical clarity, making it an ideal choice for applications that require transparency.

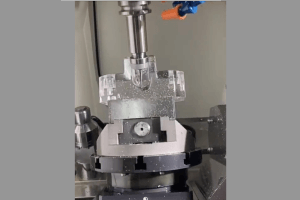

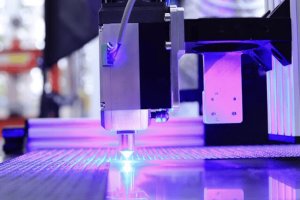

Acrylic is easy to machine and can be CNC machined into a variety of shapes and sizes. It can also be easily polished, making it a popular choice for applications that require a high-gloss finish. In addition, acrylic is resistant to weathering, UV light, and chemicals, making it a suitable choice for outdoor applications.

One of the key advantages of acrylic is its affordability, making it a cost-effective alternative to other materials such as glass. Acrylic is also available in a wide range of colors and finishes, allowing designers and manufacturers to create custom parts that meet their specific requirements.

Overall, acrylic is an excellent choice of material for CNC machining due to its versatility, durability, and cost-effectiveness.