The Resurgence of a Modern Classic: An Introduction to Aluminum Siding

When I embarked on the journey to revamp my home’s exterior, I sought a material that was durable, stylish, and low-maintenance. That’s when I rediscovered aluminum siding, a material I initially overlooked, assuming it was merely a dated feature of my grandparents’ post-war home. To my amazement, modern aluminum siding, precision-crafted through advanced CNC machining techniques, has evolved into a sleek, high-performance solution that blends rugged durability with contemporary elegance. My experience with aluminum siding has reshaped my view of home exteriors, and I’m thrilled to share why it became my top choice for a house that’s both beautiful and built to last.

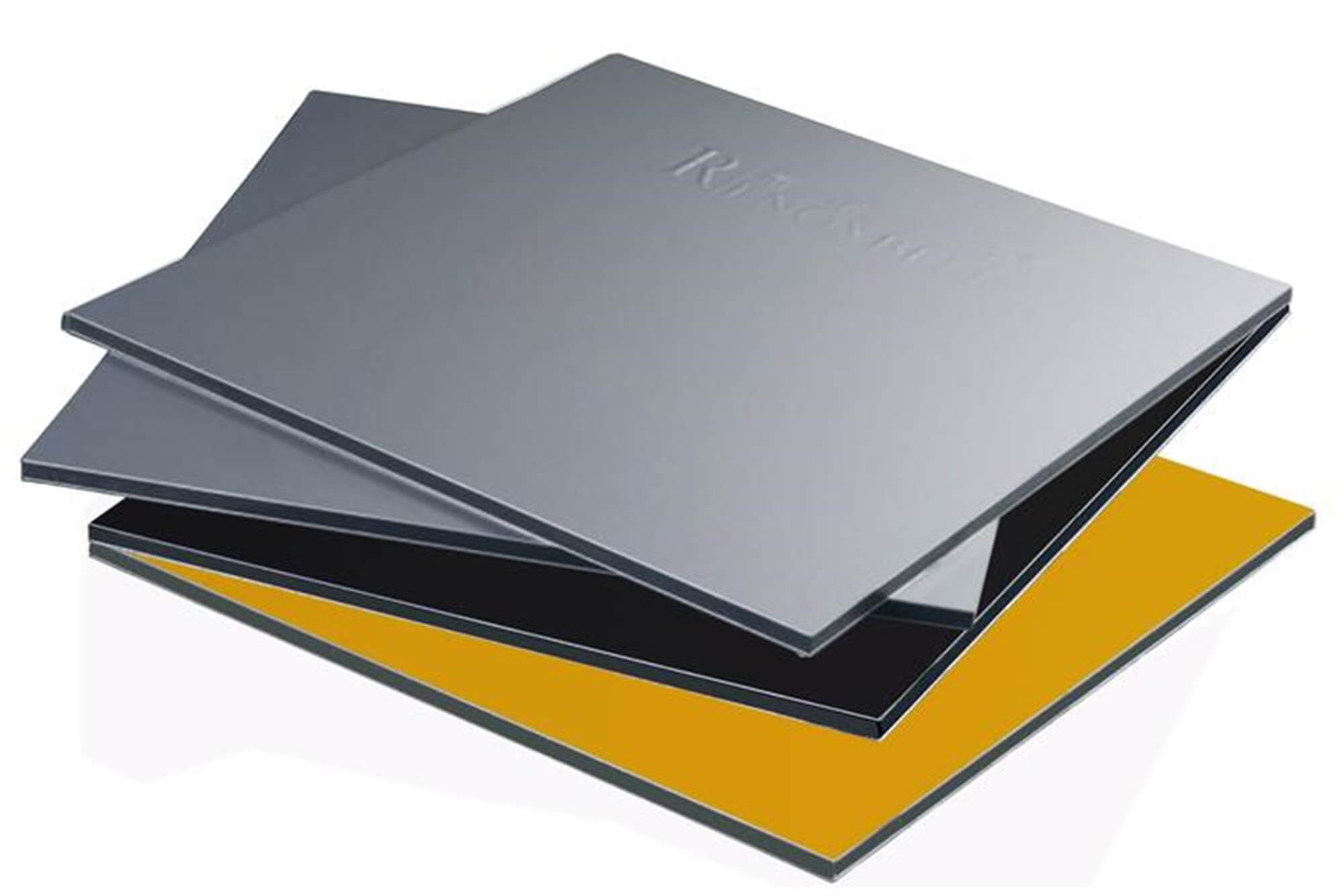

Defining Aluminum Siding: More Than Just a Metal Sheet

I quickly learned that aluminum siding is far more than simple metal panels—it’s a meticulously engineered exterior cladding system designed to protect and enhance buildings. Crafted from high-grade aluminum alloys like 3003, 3005, and 3105, aluminum siding is built to withstand extreme weather, from blistering summer heat to freezing winter snowstorms. I was particularly impressed by the manufacturing process of aluminum siding: aluminum coils are chemically treated to resist oxidation, painted for both aesthetic appeal and added protection, and then baked with enamel to create a range of textures, from smooth and modern to woodgrain for a natural look. This process makes aluminum siding lightweight, exceptionally durable, rust-proof, pest-resistant, and fire-resistant—qualities that gave me confidence in choosing it for my home’s exterior.

A Brief History: From Post-War Innovation to 21st-Century Mainstay

Exploring the history of aluminum siding sparked a nostalgic connection for me. Its story began in the late 1930s and gained traction after World War II, when homeowners sought practical solutions for their homes. In 1947, innovator Jerome Kaufman introduced “baked-on” color siding, revolutionizing exteriors with the promise of never needing to repaint. My parents’ old house had aluminum siding from that era, and I vividly recall their stories of how it freed them from the constant upkeep of wood. By the 1960s and 70s, vinyl siding stole the spotlight with its lower cost, but recent advancements in manufacturing, texturing, and color technology have revitalized aluminum siding. Today, it’s a stylish, durable choice that feels both timeless and cutting-edge, perfectly aligning with my vision for a modern yet classic home.

Benefits of Aluminum Siding for Homeowners

Choosing aluminum siding for my house was a decision I’ll never regret. Its benefits extend far beyond aesthetics, offering practical advantages that have made my life easier and my home more resilient. For me, aluminum siding strikes the perfect balance of function, style, and long-term value.

Unmatched Durability and Longevity

I’ve watched aluminum siding stand strong against brutal weather—high winds, torrential rain, and even the occasional hailstorm—and it still looks pristine. With a lifespan of 20 to 50 years, I’m confident my aluminum siding will protect my home for decades, possibly outlasting the structure itself. Unlike wood, it doesn’t rot, warp, or become brittle in extreme temperatures, which is a huge relief living in a region with unpredictable weather patterns.

Low-Maintenance Advantage

Before aluminum siding, I dreaded the thought of spending weekends painting or staining a wooden exterior. With aluminum siding, maintenance is a breeze—I simply rinse it annually with a garden hose and mild detergent, and it sparkles like new. When the factory finish begins to fade, I can easily repaint it to refresh the look without the costly replacements vinyl often requires. The low upkeep of aluminum siding has given me more time to enjoy my home rather than constantly maintaining it.

Superior Resistance

To me, aluminum siding feels like a protective shield for my house. Its fireproof nature is a game-changer in my wildfire-prone area, potentially even lowering my insurance premiums. It’s also waterproof, preventing rot, mold, and mildew, and completely rust-proof, which is ideal for my coastal climate where salty air can be harsh. Best of all, aluminum siding is pest-proof, keeping termites and rodents from compromising my home’s structure. These qualities make aluminum siding a worry-free choice that lets me sleep soundly.

Energy Efficiency and Sustainability

Since installing aluminum siding, I’ve noticed a welcome drop in my cooling bills, thanks to its heat-reflective surface that keeps my home cooler in summer. Adding insulated panels has made my home even more energy-efficient, reducing my reliance on air conditioning. What truly won me over is the sustainability of aluminum siding—it’s 100% recyclable, often made with up to 67% recycled content. Unlike vinyl, which clogs landfills, aluminum siding supports my commitment to a greener lifestyle, making me feel good about my choice.

Potential Drawbacks and Considerations

No material is flawless, and my experience with aluminum siding has taught me its unique characteristics. Its lightweight nature makes it susceptible to dents from hail or stray objects like a kid’s baseball, but I opted for thicker-gauge panels to minimize this risk. Over time, the factory finish may fade or develop a chalky residue, but I see this as an opportunity to repaint and refresh my home’s style. I’ve also noticed that aluminum siding can be noisy during heavy rain or temperature swings, producing a faint pinging sound, though proper installation and insulation have kept this to a minimum. While the sleek, modern look of aluminum siding perfectly suits my contemporary home, I can see why someone with a historic Victorian or Colonial house might prefer the traditional warmth of wood.

Aluminum Siding vs. The Competition

Deciding on aluminum siding required comparing it to other materials, and my research and experience shaped my choice. Here’s my breakdown:

| Material | Cost (per sq. ft.) | Lifespan | Durability | Maintenance | Eco-Friendliness |

| Aluminum Siding | $6 – $10 | 40+ years | Fireproof, rust-proof, pest-proof | Low: Wash, repaint | Excellent: 100% recyclable |

| Vinyl | $4 – $12 | 20-40 years | Prone to cracking, not fireproof | Very low: Wash only | Poor: Hard to recycle |

| Fiber Cement | $6 – $15 | 50+ years | Fire-resistant, pest-resistant | Low: Wash, repaint | Good: Sustainable |

| Wood | $7 – $16 | 20-40 years | Vulnerable to rot, pests, fire | High: Paint, seal often | Good: Renewable |

| Steel | $7 – $16 | 40+ years | Dent-resistant, may rust | Low: Repair scratches | Excellent: Highly recyclable |

I chose aluminum siding over vinyl for its superior fire resistance and durability, especially in extreme temperatures. Compared to fiber cement, aluminum siding was easier and cheaper to install due to its lighter weight. Wood’s classic beauty was tempting, but its high maintenance and fire risk didn’t suit my lifestyle. Against steel, aluminum siding won for its natural rust resistance, a must for my coastal home.

Modern Aluminum Siding Styles and Finishes

The style versatility of aluminum siding truly excited me. From classic horizontal lap siding to sleek vertical panels, I opted for board & batten to give my home a rustic-modern charm. The color palette—sleek greys, crisp whites, earthy greens, or bold blues—let me choose a charcoal shade that blends beautifully with my natural surroundings. I went with a woodgrain texture for a warm, natural look without the upkeep of real wood, paired with a satin sheen for durability and easy cleaning. Aluminum siding transformed my home into a stylish statement that reflects my personality.

Investing in Aluminum Siding: Cost Analysis

Installing aluminum siding on my 2,000-square-foot home cost between $12,000 and $20,000, or $6 to $10 per square foot, which felt like a smart investment compared to pricier options like wood or steel. Materials ranged from $3 to $7 per square foot, labor from $3 to $6, and removing old siding added $0.70 to $3.75 per square foot. I chose thicker-gauge aluminum siding for extra durability, especially in my hail-prone area, which increased the upfront cost but gave me peace of mind. With a 70-77% return on investment and a major boost in curb appeal, aluminum siding has proven to be a financially savvy choice that makes my home stand out.

Homeowner’s Guide to Aluminum Siding Care

I’ve learned that professional installation is critical to maximizing aluminum siding’s longevity. My contractor ensured a waterproof underlayment and precise panel placement to accommodate the metal’s natural expansion and contraction. For maintenance, I clean my aluminum siding annually with a garden hose and Simple Green, using a bleach-and-water mix for stubborn mold stains. Small dents are easily fixed with auto-body filler, and I patched a minor hole with butyl caulk and a spare piece of siding. When the finish eventually fades, I plan to repaint with high-quality acrylic latex paint using an airless sprayer for a professional, long-lasting result. These simple steps keep my aluminum siding looking as good as new.

Conclusion

If you’re considering a home exterior upgrade, I can’t recommend aluminum siding enough. Reach out to a local contractor or explore manufacturer websites to discover the perfect style for your home. For me, aluminum siding has been a game-changer, combining durability, low maintenance, and modern style into a home I’m proud to call my own. It’s not just a practical choice—it’s a reflection of my values, blending sustainability, beauty, and resilience in a way that makes my house truly feel like home.

FAQ:

Q: How long does aluminum siding really last? A: With proper installation and routine maintenance, aluminum siding can easily last 40 years or more. In many cases, its lifespan is limited only by the life of the structure it is attached to.

Q: Is aluminum siding noisy? A: It can be. Because it’s metal, it can produce a pinging sound during heavy rain or hail, and it may make subtle noises as it expands and contracts with temperature changes. However, using thicker-gauge siding and installing it over an insulation board can significantly reduce these sounds.

Q: What is the number one cause of problems with aluminum siding? A: The two most common issues are its susceptibility to denting from impacts and the eventual fading or chalking of its factory-applied paint finish due to long-term sun exposure.

Q: Can you replace just one damaged piece of siding? A: Yes, it is entirely possible to have a professional replace a single damaged panel without having to reside the entire house. This makes repairs for isolated damage more manageable and cost-effective.

Q: Is aluminum siding cheaper than vinyl? A: Generally, no. Vinyl siding typically has a lower upfront material and installation cost. However, aluminum often provides better long-term value due to its superior durability, fire resistance, and the ability to be repainted to extend its aesthetic life.

Q: Is aluminum a good choice for coastal or wildfire-prone areas? A: It is an excellent choice for both. Its natural resistance to rust and corrosion makes it ideal for coastal environments with salt air, and its non-combustible, fire-proof nature makes it one of the safest siding options for areas with a high risk of wildfire.

Q: Do I have to repaint aluminum siding? A: Eventually, yes. While the factory finish is very durable, it will likely begin to fade or chalk after 10 to 15 years of sun exposure. Repainting is the best and most cost-effective way to restore the siding’s appearance and add another layer of protection, extending its life for many more years.

Reference:

https://en.wikipedia.org/wiki/Siding_(construction);

https://hkxb.buaa.edu.cn/CN/abstract/abstract8729.shtml;

https://www.epa.gov/lead/renovation-repair-and-painting-program-homeowners ;

Other Articles You Might Enjoy

- Aluminum Angle Uncovered: Tips for Machining, Industry Application, and Beyond

Introduction: Unique Advantages of Aluminum Angle I’ve always been fascinated by the lightweight properties of aluminum angle and the sheer range of possibilities it opens up for different industries. Aluminum…

- Aluminum Plate for CNC Projects: A Practical Buying and Application Guide

Introduction If you've ever worked on a CNC project—whether in a garage workshop or a full-scale production facility—chances are you've handled an aluminum plate. I remember the first time I used…

- How to Polish Aluminum Parts in Precision Machining: A Professional Workflow Guide

Introduction I’ve worked in industrial manufacturing for over a decade. One of the biggest production bottlenecks I've faced is achieving quality surface finishes without disrupting manufacturing speed. Aluminum polishing is…

- Aluminum Square Tubing for CNC Projects: From Material Choice to Precision Cutting

Introduction When I first started getting into CNC machining, I experimented with a bunch of different materials — wood, steel, plastics. But over time, aluminum square tubing became my default choice. It's…

- 80/20 Aluminum Machining: From Standard Profiles to Precision Structures

Chapter 1:Introduction Why 80/20 Aluminum and CNC Are the Perfect Match? I first came across 80/20 Aluminum a few years back, working on a small automation project. At the time, I was…