Introduction to Precision CNC Machining and Metal Choices

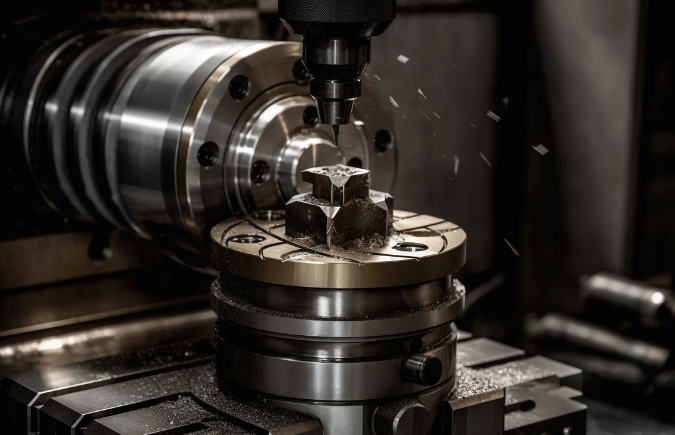

Precision CNC Machining is a crucial technique in the manufacturing industry, leveraging the power of computers for highly accurate and efficient product creation. Technicians input specific software programs into machines which then follow these instructions to produce precise components. There are several materials suitable for this process, among which aluminum and brass are most popular due to their unique properties. However, choosing between these metals can pose a dilemma as the ideal choice depends greatly on project specifics. Aluminum is renowned for its light weight and resistance to corrosion making it beneficial for delicate designs and products exposed to harsh weather conditions. On the other hand, brass comes with improved malleability and aesthetic appeal, therefore being more suited to ornamental projects or parts requiring complex shapes.

Understanding Precision CNC Machining

Precision Computer Numerical Control (CNC) machining encompasses a set of technologies and processes utilized in manufacturing to ensure high-precision parts are produced. In essence, it refers to an automated method where pre-programmed computer software dictates the movement of factory machinery and tools. With its level of precision, this technology has found wide-spread use in industries such as automotive, aerospace and electronics which require highly accurate components.

The choice of material plays a crucial role in precision CNC machining. This is primarily due to factors such as the material’s machinability, strength, conductivity, cost-effectiveness, and potential functionality within its end-use environment. For instance, aluminum is preferred because of its lightweight nature and good thermal conductivity making it ideal for applications involving heat transfer. On the other hand, brass offers better corrosion resistance and higher electrical conductivity than aluminum, hence suitable for electrically charged environments.

- Automated Method: The use of computer programs to control machine tools improves accuracy and efficiency, eliminating human error and speeding up the production process.

- Material Choice: Different materials behave differently under various machining conditions. Aluminum may be easier to machine but can also wear out tooling faster than harder materials like steel. Therefore, understanding the properties of each material helps optimize machining procedures.

Pros and Cons of Using Aluminum in Precision CNC Machining

When considering aluminum for precision CNC machining, it’s important to weigh the following pros and cons:

- Pros:

- Corrosion resistance

- Economical production costs

- High strength-to-weight ratio

- Recyclability

- Suitability for rapid tooling manufacturing

- Low maintenance requirements

- Customizability

- Cons:

- Conductivity of electricity

- Low melting point

Pros and Cons of Using Brass in Precision CNC Machining

In precision CNC machining, brass embodies several unique properties and benefits that make it an ideal choice for numerous projects. Notably, its machinability stands out; brass requires less power to machine compared to many other metals due to its softness and ductility, allowing for higher cutting speeds and a smoother finishing surface on the part being worked on. Moreover, its anti-corrosive properties and fantastic heat conduction capacity add to its appeal.

However, working with brass also presents certain challenges. Its softness, while beneficial in terms of machinability, poses durability issues for parts meant to sustain substantial mechanical stress or strains. In such cases, high-strength materials like steel are typically more suitable. Furthermore, the cost of brass can be prohibitive for larger scale projects as compared to cheaper alternatives like aluminum.

A practical example showcasing the effectiveness of using brass would be in the manufacturing of small components for musical instruments such as trumpets and trombones. The precise dimensions required in these components demand the use of precision machines, while the natural acoustic properties of brass makes it a prime candidate for such applications.

Comparison Between Aluminum and Brass for Precision CNC Machining

When deciding on the ideal metal for your precision CNC machining project, it’s crucial to make a thorough comparison between aluminum and brass. First of all, in terms of cost-efficiency, aluminum is typically cheaper than brass, making it more affordable for large-scale projects. However, if durability is your primary concern, brass tends to be stronger and have better wear resistance.

- Machinability: Both metals exhibit excellent machinability although some find that aluminum allows faster material removal rates.

- Thermal Conductivity: Aluminum has superior thermal conductivity, which can be advantageous in certain applications.

- Aesthetics: Brass provides a gold-like appearance while aluminum presents a modern, sleek silver look. Note that aesthetics might be important depending on the usage context of the finished part.

To determine the best-suited metal for specific project needs, manufacturers must assess requirements in terms of cost, durability, speed, thermal properties, and visual appeal before making an informed choice.

Conclusion

In wrapping up, we’ve explored the key characteristics of aluminium and brass in CNC machining applications. Aluminium is lightweight yet strong with excellent heat dissipation abilities, making it suitable for parts where weight and temperature considerations are crucial. On the other hand, brass’ superior machinability, strength and resistance to corrosion render it ideal for areas requiring durability and precision.

- Key takeaway 1: Aluminum is suitable for projects that demand light-weightedness as well as thermal efficiency.

- Key takeaway 2: Brass proves to be ideal in cases demanding high strength, precise machining and resistance to weathering factors.

This discussion underscores the importance of thoroughly assessing each project’s unique requirements before settling on a preferred metal. Evaluating parameters like functionality, environmental conditions, production costs and more will contribute towards successful project execution.

Other Articles You Might Enjoy

- Precision CNC Machining: Aluminum vs. Brass for Your Custom Parts

Introduction to Precision CNC Machining and Custom Parts Precision CNC (Computer Numeric Control) machining is a cutting-edge manufacturing process that utilizes computer-controlled machinery to produce intricately designed custom parts, adhering…

- Elevating Precision Standards through Chamfer in CNC Machining

1. Introduction: The Pursuit of Unparalleled Precision In the realm of CNC machining, precision is paramount. This section introduces the article by exploring the significance of precision in manufacturing and…

- Precision Prowess: Unveiling the Advantages of China CNC Machining

1. Introduction: The Role of Precision in Manufacturing Excellence In this introductory section, we delve into the critical role that precision plays in manufacturing and set the stage for an…