Precision CNC Machining and the Role of Silicon Nitride vs. Tungsten Carbide

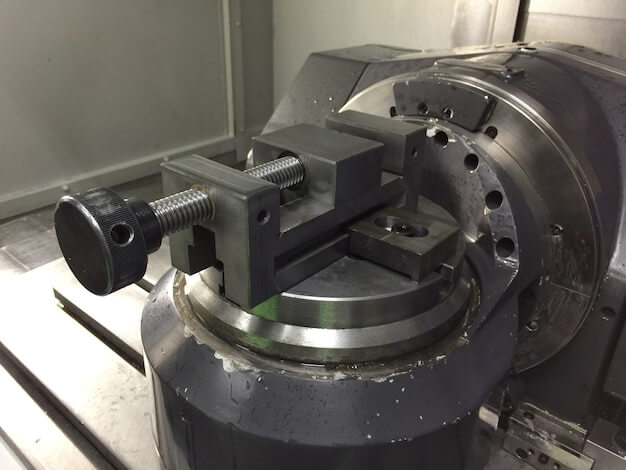

Precision CNC machining is a pivotal process in manufacturing that leverages computer numerical control (CNC) for creating intricate parts with high dimensional accuracy. Key to its successful implementation are Silicon Nitride and Tungsten Carbide, two materials extensively used due their unique properties. Silicon Nitride exhibits excellent resistance to thermal shock and wear while having low friction coefficient, making it advantageous for various cutting tools. On the other hand, Tungsten Carbide distinguishes itself by offering exceptional hardness, heat resistance, and long service life.

- Silicon Nitride: Highly resistant to wear and thermal shock, making it ideal for cutting tools applications.

- Tungsten Carbide: Known for its extreme hardness and resistance to heat, ensuring longevity.

In this comparative study, we will delve deeper into how these two materials fare in precision CNC machining, identifying their strengths & weaknesses, as well as guidance on their optimal application context.

Silicon Nitride Explained

Silicon Nitride, a synthetically produced ceramic material with a unique combination of robust mechanical properties and resistance to temperature fluctuations, stands out in the world of CNC precision machining. Its lower density compared to other ceramics like tungsten carbide allows for lighter components, making it ideal for applications where weight is a crucial factor. It also has superior thermal shock resistance which ensures dimensional stability even at high temperatures, such as machining automotive parts.

One real-world example that demonstrates its utility is seen in cutting tools used for hard steel materials. The hardness, toughness, and heat-resistance of Silicon Nitride mean that tool edge sharpness can be maintained longer, reducing down-time for tool changes.

- Hardness: Making it ideal for heavy-duty industrial usage where physical stress is high.

- Toughness: Reduced risk of cracking or fracturing under intense operational conditions.

- Heat-Resistance: Suitable for usage in high-temperature environments without deforming or melting.

However, using silicon nitride isn’t without potential drawbacks. These might include its somewhat limited toughness when exposed to sudden temperature drops and its slightly less wear-resistant nature compared to some other ceramics like boron carbide and alumina.

Exploring the Characteristics and Functionalities of Tungsten Carbide in Precision CNC Machining

Tungsten carbide is a popular material in precision CNC machining due to its exceptional hardness, wear resistance, and thermal conductivity. It is widely used for cutting tools, inserts, and wear parts in various industries such as automotive, aerospace, and manufacturing. The unique properties of tungsten carbide make it an ideal choice for applications that require high precision and durability. When utilizing tungsten carbide in precision CNC machining, it is crucial to partner with a Precision Machining Service that has expertise in working with this advanced material to ensure optimal results.

Performance Comparison Between Silicon Nitride and Tungsten Carbide in Precision CNC Machining

When it comes to precision CNC machining, both silicon nitride and tungsten carbide bring their unique properties into play. Silicon nitride stands out for its high fracture toughness – an aspect that makes it perfect for operations involving severe mechanical shocks. For instance, in milling hard steel material or drilling nodular cast iron materials, the robustness of silicon nitride becomes more beneficial. On the other hand, tungsten carbide is cherished for its unequalled hardness and wear resistance which increases tool longevity significantly. It becomes a superior choice in tasks like cutting glassy metals, creating smooth surfaces, or operating under continuous high-speed condition.

Suitability greatly depends on specific requirements and types of machinery. Silicon nitride’s lower thermal conductivity reduces heat build-up during operation, making it suitable for long hour applications while tungsten carbide’s rigidity is preferred where dimensional stability is critical. Notably consistent across various applications is silicon nitride’s better performance in shock-absorbing machining exercises and tungsten carbide leading in wear resistance-related tasks.

Silicon Nitride versus Tungsten Carbide in Precision CNC Machining

Upon analyzing expert opinions, research studies, and user experiences, it can be concluded that the choice between silicon nitride and tungsten carbide is highly influenced by specific machining conditions. Both materials offer unique advantages in precision CNC machining. Silicon nitride exhibits superior thermal shock resistance and excellent toughness – features particularly beneficial under intermittent cutting conditions or when machining hard materials. It also has a low level of friction against metals which significantly reduces adhesive wear.

On the other hand, Tungsten carbide emerges as a more appropriate choice when stability and rigidity are paramount, its intrinsic hardness makes it an ideal candidate for continuous high-speed metal cutting operations. Take as an example this case: in a study where a series of drilling processes was conducted using both materials, tungsten carbide demonstrated better performance on cast iron due to its excellent hot hardness properties and balanced strength-to-rigidity ratio.

- Silicon nitride receives preference under intermittent cutting conditions with its superior thermal shock resistance.

- Tungsten carbide demonstrates better performance during continuous high-speed metal cutting due to intrinsic hardness and optimal strength-to-rigidity balance.

Therefore, neither material categorically outperforms the other; rather, their usage efficiency lies within varying machining contexts and application-specific requirements.

Other Articles You Might Enjoy

- Precision CNC Machining for the Aerospace Defense Industry

Precision CNC Machining in the Aerospace Defense Industry In modern manufacturing sectors, precision Computer Numerical Control (CNC) machining plays a critical role. It is an automated process that uses pre-programmed…

- The Evolution of CNC Machining: From Aluminum to Composite Materials

Introduction to CNC Machining CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to initiate and manipulate machine tools, such as lathes, mills and grinders. With…

- Advanced Ceramics: The Future of High-Precision Machining?

Introduction to Advanced Ceramics and High-Precision Machining In the field of manufacturing, advanced ceramics have emerged as a crucial element. These are essentially non-metallic, inorganic compounds that exhibit a range…