Micro injection molding is a specialized form of manufacturing that enables the production of small and intricate plastic parts with high precision. It stands as an essential technique in various industries, particularly where components must be produced on a micro-scale with tight tolerances, such as medical devices or microelectronics. The process involves injecting molten material into a mold which contains a cavity shaped like the desired part. Upon cooling and solidification, the component can be ejected from the mold, reflecting the required dimensions often down to the micron level. This capability not only supports advancements in miniaturization but also leads to significant cost savings through material efficiency and the ability to mass-produce precise components at scale.

Principles of Micro Injection Molding

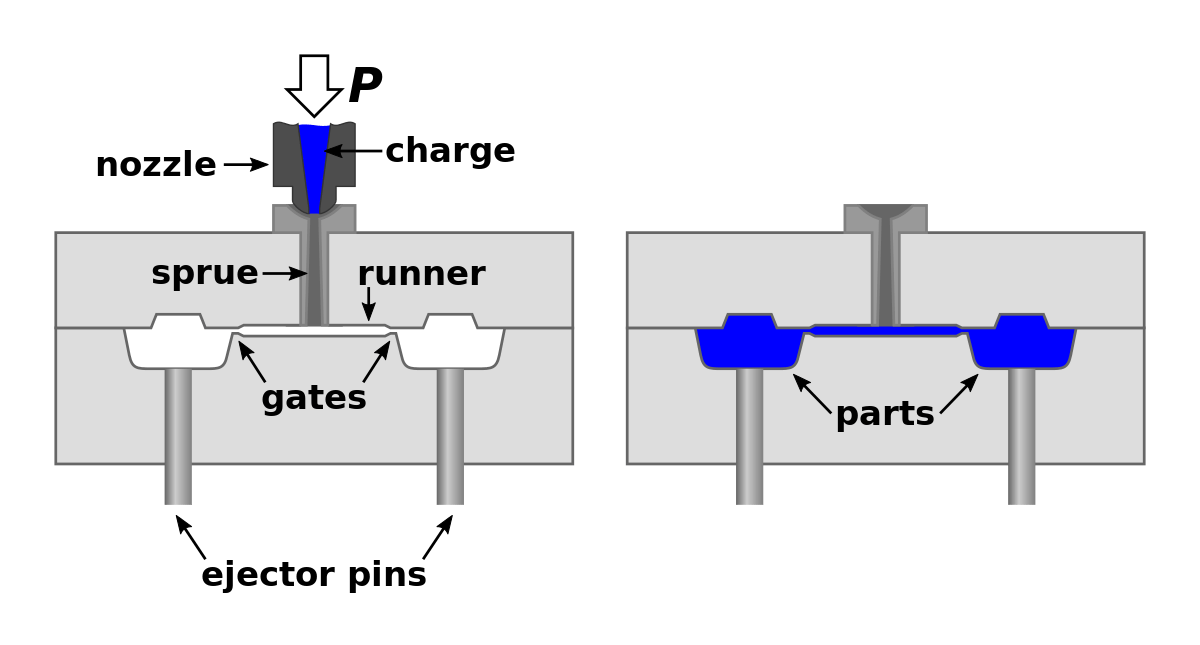

Micro injection molding is a manufacturing technique designed for the production of small, intricate components with high precision. The process begins with the preparation of a thermoplastic or thermoset material in pellet form, which is then fed into the micro injection molding machine. A screw mechanism heats and plasticizes the raw material, propelling it towards the mold cavity through an injection nozzle. Once in the cavity, the molten polymer takes on the exact shape of the mold under high pressure. Key equipment includes the micron-sized molds that feature extreme accuracy, precision screws for consistent material flow, and specialized injectors to manage smaller volumes effectively. Additionally, an advanced clamping system holds the mold together during material injection and solidification. Control systems are also integral for maintaining precise temperature, pressure, and timing during the entire cycle to ensure repeatable quality of micro-sized parts.

Benefits of Micro Injection Molding

Micro injection molding excels at producing small components with a high degree of precision and accuracy, ensuring exact specifications are met with consistent repeatability. This precise manufacturing reduces materials usage and scrap production, leading to a significant cost reduction for high-volume production runs. Noteworthy is its contribution toward enhanced part strength and quality, as the process allows for tight control over material properties during production. Furthermore, this technology’s efficiency results in reduced waste generation, thus minimizing environmental impacts and promoting sustainability in industrial practices.

Applications of Micro Injection Molding

Micro injection molding plays a pivotal role across various industries due to its ability to produce high-precision, micro-sized parts. In the medical industry, this technique is essential for manufacturing miniature components such as surgical tools, microneedles, and small implants that require intricate detailing and strict compliance with medical standards. The electronics sector benefits from micro injection molding through the production of tiny connectors and advanced sensors that are integral in modern devices, ensuring connectivity and functionality on a microscopic scale. Similarly, the automotive industry relies on this technology for creating precision components like small gears or complex fuel injector nozzles that must meet precise tolerances and durability requirements. As an example case study, consider micro injection molding’s application in producing hearing aid components which demand both miniaturization and absolute precision to provide a comfortable fit and optimal performance for users — showcasing the method’s unparalleled capability to innovate and enhance product design.

Advanced Materials Used in Micro Injection Molding

The selection of materials for micro injection molding is critical, with various types of polymers offering distinct attributes tailored to specific applications. Engineering plastics such as Polyether Ether Ketone (PEEK) and Polymethyl methacrylate (PMMA), are favored for their high strength-to-weight ratios, thermal stability, and optical clarity, making them suitable for medical devices and precision optics. Thermoplastic elastomers (TPEs), on the other hand, provide flexibility and durability, essential traits for creating small moving parts or seals found in microfluidics or electronics. With performance intricately linked to material properties, choosing an appropriate polymer is fundamental not only for achieving dimensional accuracy but also for ensuring long-term functionality in diverse conditions ranging from harsh chemical environments to mechanical stressors.

Future Trends in Micro Injection Molding

The horizon for micro injection molding is vibrant, marked by promising technological innovations alongside an uptick in demand from emerging markets. Innovations such as advancements in nano-materials and the intertwining of microfluidics with micro-molding are set to propel capabilities forward. These materials offer exceptional strength-to-weight ratios and enhanced functionality, enabling the production of components with complex geometries and precise tolerances. Meanwhile, sectors like biotechnology, pharmaceuticals, and telecommunications within emerging economies are experiencing ascension, driving demand for miniature and high-precision plastic parts. As these regions invest more in healthcare infrastructure and consumer electronics, the need for cost-effective and highly scalable solutions offered by micro injection molding will become even more pronounced.

Other Articles You Might Enjoy

- Micro Injection Molding: Principle, Benefits, and Applications

Introduction to Micro Injection Molding Micro injection molding is a high-precision manufacturing process used in producing miniature and intricate plastic parts. This procedure, employing specialised machines with high-pressure moulding capabilities…

- Micro Injection Molding: Principle, Benefits, and Applications

Introduction to Micro Injection Molding Micro injection molding is an advanced manufacturing technique that miniaturizes traditional injection molding processes. The principle of micro injection molding revolves around producing tiny, intricate…

- Micro Injection Molding: Principle, Benefits, and Applications

Introduction to Micro Injection Molding Micro injection molding is a specialized form of manufacturing that enables the production of small and intricate plastic parts with precision. The process involves injecting…