Introduction to 3D Printing Technology and SLS vs SLA Materials

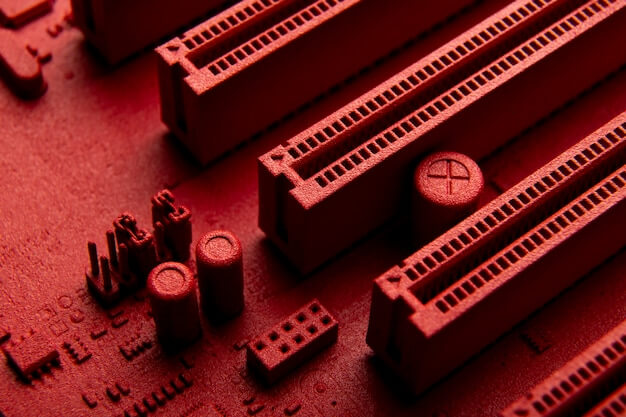

In the world of manufacturing, 3D printing technology has emerged as a revolutionary tool with its ability to transform digital designs into physical objects. This procedure functions on an additive principle, assembling layers upon layers to create three-dimensional products. Amongst the multitude of 3D printing technologies, Selective Laser Sintering (SLS) and Stereolithography (SLA) are two main types worth understanding.

China Online CNC Machining Service

SLS works by using lasers to sinter powdered material, forming the desired shape layer by layer. This method is cherished for its capacity to print strong, durable parts without supports and it can be used with a diverse range of materials including nylon, plastics or metal powders.

On the other hand, SLA functions by deploying ultraviolet light beam to harden photosensitive liquid resin, laying down one layer at a time until your object takes full form. SLA holds the advantage in delivering high resolution prints with smooth surface finishes and fine detailing, often favoured for aesthetic prototypes and models.

Understanding Selective Laser Sintering (SLS): Features, Benefits, and Limitations

Selective Laser Sintering (SLS) is a widely used 3D printing technology that offers unique features, benefits, and limitations.

1. Features of SLS

SLS technology has the following key features:

- Unsintered Powder Support: One of the main advantages of SLS is that the unsintered powder acts as a support during the construction of the component, eliminating the need for separate support material. This enables the production of products with complex geometry.

- Layer-by-Layer Production: SLS uses a programmed laser beam to melt and sinter polymers or ceramic granules layer by layer, allowing for precise and detailed construction.

2. Benefits of SLS

SLS offers several benefits for 3D printing applications:

- Complex Geometry: The ability to produce products with complex geometry is a significant advantage of SLS. This makes it suitable for applications that require intricate and detailed designs.

- Durability and Strength: SLS produces parts with excellent durability and strength, making them suitable for functional prototypes and end-use products.

- Material Versatility: SLS can work with a wide range of materials, including polymers and ceramics, providing versatility in material selection for different applications.

3. Limitations of SLS

While SLS has many advantages, it also has some limitations to consider:

- Raw Material Limitations: SLS is currently limited to certain materials, such as plastic polymers (e.g., PA-11, PA-12, PEEK). It may not be suitable for other common materials like metals.

- Health Factors: The inhalation of powdered materials used in SLS can pose health risks, requiring proper safety measures and precautions.

- Cost and Post-Processing: SLS printers can be expensive, and post-processing of SLS-printed parts can be challenging and time-consuming.

4. Summary

In summary, Selective Laser Sintering (SLS) is a 3D printing technology that offers features such as unsintered powder support and layer-by-layer production. It provides benefits such as the ability to create complex geometry, durability, and material versatility. However, it also has limitations in terms of raw material options, health factors, and cost considerations. Consider the specific requirements of your project to determine if SLS is the right 3D printing technology for your needs.

Understanding Stereolithography (SLA)

Stereolithography, popularly known as SLA is a 3D printing technology that works on the principle of light-induced polymerization. In simple terms, the process involves using UV-light to cure layers of liquid resin onto a platform until they solidify into a three-dimensional object.

- Benefits: The foremost advantages are its exceptional accuracy and surface finish detail. It offers high precision making it ideal for applications requiring great attention to detail.

- Disadvantages: However, the lacunas lie in limited material options and durability of finished products. The end products tend to be somewhat fragile due to the brittleness of the cured resin.This restricts their application in areas where robustness is crucial.

Incorporating this technique could enhance the finishing touch of minute details, although care must be taken owing to potentially brittle completed systems.

Comparison Between SLS and SLA

Selective Laser Sintering (SLS) and Stereolithography Apparatus (SLA) may fall similarly under the umbrella of 3D printing technology, but flaunt unique differences in functionality and usability that makes each suitable for specific uses. The key distinction between SLS and SLA lies primarily in how they form layers.

In terms of functional disparity, SLS uses powdered material to build structures from bottom-up by sintering successive layers together using a high power laser. On the other hand, SLA follows a photochemical process where ultraviolet light polymerizes liquid resin to harden it layer-by-layer on top of one another. This means, whereas SLS can print with metal and plastic materials, SLA is restricted to only photosensitive resins.

- Flexibility and durability make SLS ideal for prototypes or operational parts in industries such as automotive manufacturing and aerospace.

- Meanwhile, precision, resolution, and surface finish set SLA apart, making it perfect for highly detailed objects like jewelry molds, dental models, or prototyping of medical devices such as hearing aids.

Accordingly, choosing between these two technologies largely depends on the end-product you desire: if detail oriented items are required then SLA should be your go-to choice while if durable parts under complex mechanical stresses are demanded then SLS would suit better.

Conclusion: Selecting Between SLS and SLA Materials

In sum, both SLS (Selective Laser Sintering) and SLA (Stereolithography) techniques offer unique benefits in 3D printing technology. SLS, which utilizes a laser to fuse powdered material into solid form, is renowned for its ability to produce durable components with intricate geometries. Conversely, SLA employs an ultraviolet light source to cure photosensitive liquid resin, resulting in high-resolution output ideal for products demanding precision and accuracy. The choice between these two methods ultimately depends on the user’s specific requirements.

Here are some key considerations when choosing between SLS and SLA materials:

- If durability and strength is of prime concern, SLS might be the most suitable option.

- If you require a higher degree of resolution and surface finish, then SLA should be considered.

- Lastly, cost-effectiveness must also factor into your decision as each process has different operational prices, material costs and post-processing needs.

Understanding these technical principles can significantly assist users in identifying the appropriate 3D printing methodology for their distinct needs and achieving the desired results.

Other Articles You Might Enjoy

- SLS vs. SLA Materials: Choosing the Right 3D Printing Technology

Introduction to 3D Printing Technology: Material Selection and Techniques In the realm of rapid prototyping and manufacturing, 3D printing technology has revolutionized the industry by allowing for quick and precise…

- Understanding 3D Printing: Processes, Benefits, and Uses

Introduction to 3D Printing Technology 3D printing, a transformative approach to manufacturing and prototyping, enables the creation of complex structures from digital blueprints by successively layering material until a three-dimensional…

- 3D Printing Resins: Standard vs. Engineering-Grade Options

Introduction to 3D Printing Resins In the vast field of additive manufacturing, 3D printing resins hold a significant place due to their unique properties and wide-ranging applications. These thermosetting materials…