Introduction to Flange Technology and Its Evolution

Flange technology, the backbone of numerous industries, has evolved significantly over the years. Initially, flanges were simple, rudimentary connections used primarily in plumbing and piping. However, as industry demands grew, so did the complexity and capabilities of flange technology. The advent of precision manufacturing techniques, especially Computer Numerical Control (CNC) machining, has revolutionized flange production. With the development of Internet technology, many companies have begun to provide online cnc service and receive flange production needs, improving service efficiency.

One notable evolution in flange technology was the introduction of high-strength, corrosion-resistant materials. Initially, carbon steel was the material of choice due to its strength and versatility. However, as industries evolved, the need for materials that could withstand harsher environments and higher pressures became evident. This led to the adoption of stainless steel, alloy steel, and even exotic materials like Inconel and Monel in flange manufacturing. These materials not only enhanced the performance of flanges but also extended their lifespan, proving crucial in applications like offshore drilling platforms where reliability and durability are paramount.

The Role of CNC Machining in Modern Manufacturing

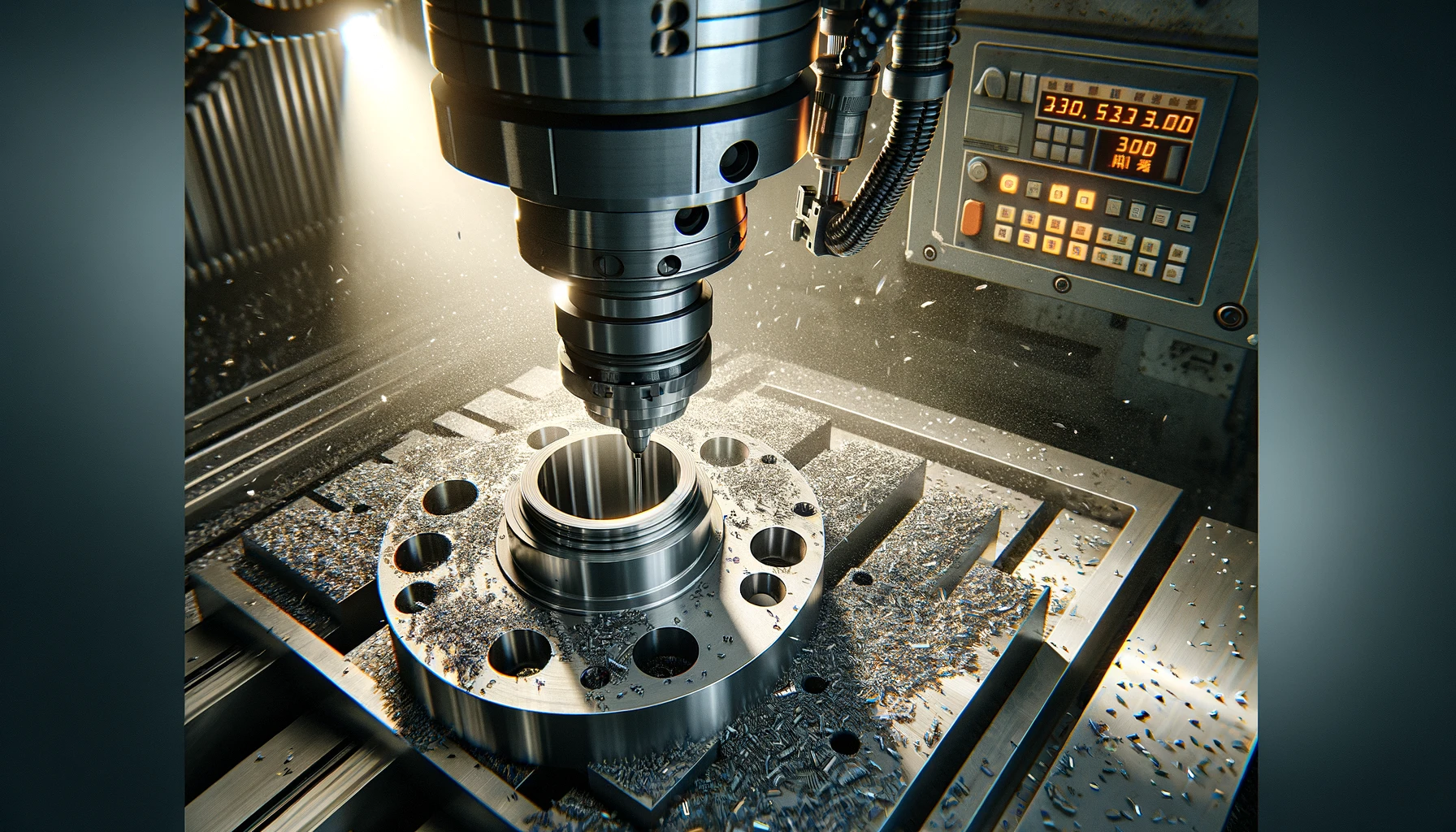

CNC machining has become a cornerstone of modern manufacturing, offering unparalleled precision, efficiency, and versatility. This technology utilizes computer-controlled machines to perform complex cutting, shaping, and drilling tasks with extreme accuracy. In the context of flange manufacturing, CNC machining has enabled the production of flanges with intricate designs and tight tolerances that were previously unattainable.

For instance, in the automotive industry, CNC machined flanges are used to ensure airtight connections in exhaust systems. The precision of CNC machining allows for the creation of flanges that perfectly match the contours of connecting pipes, minimizing the risk of leaks and enhancing the overall performance of the vehicle. A specific example can be seen in high-performance racing cars, where every component must perform flawlessly under extreme conditions. Here, CNC-machined titanium flanges are often used for their exceptional strength-to-weight ratio and resistance to high temperatures.

Challenges and Solutions in Advanced Flange Manufacturing

Despite the advancements in technology, flange manufacturing faces several challenges. One of the primary challenges is maintaining the integrity of materials during the machining process. High-performance materials like Inconel and titanium are difficult to machine due to their hardness and heat resistance, which can lead to tool wear and increased production costs.

To address this challenge, manufacturers have turned to specialized cutting tools and coolants. For example, using polycrystalline diamond (PCD) cutting tools can significantly reduce wear and tear during the machining of hard materials. Additionally, advanced cooling techniques, such as cryogenic machining where liquid nitrogen is used as a coolant, have proven effective in preserving material integrity and extending tool life.

Innovative Materials and Designs in Flange Manufacturing

The continuous pursuit of innovation in flange manufacturing has led to the exploration of new materials and designs. Composite materials, for instance, are gaining traction in the industry due to their lightweight and corrosion-resistant properties. These materials are particularly beneficial in aerospace and marine applications, where weight reduction and durability are crucial.

An innovative design that has emerged is the compact flange, which offers a smaller footprint and reduced weight compared to traditional flanges. This design is particularly useful in applications where space is limited, such as in subsea piping systems. The compact flange’s design minimizes the required bolt load, leading to a more efficient and reliable connection.

Revolutionizing Flange Production in China: Success Stories and the CNC Edge

In China, the flange production landscape has been dramatically transformed through the adoption of cutting-edge CNC technologies, showcasing a leap in manufacturing prowess. Central to this transformation is the utilization of advanced CNC machining centers like the DMG MORI 5-axis CNC machine, known for its high precision and versatility. These machines are equipped with sophisticated features such as live tooling and sub-spindle capabilities, allowing for the simultaneous machining of complex flange geometries, drastically reducing cycle times and enhancing productivity.

One exemplary success story involves a prominent Chinese flange manufacturer that employed the latest HAAS VF-6 CNC machining center to produce ultra-high-pressure flanges for a critical infrastructure project. The flanges, made from a super duplex stainless steel, required exceptional precision to withstand pressures exceeding 20,000 psi. The HAAS VF-6, with its advanced tool management system and high-speed machining capabilities, enabled the production of flanges with precise tolerances of +/- 0.005 mm, ensuring their flawless performance in harsh operating conditions.

Furthermore, the integration of IoT (Internet of Things) technology in flange production has enabled real-time monitoring and optimization of machining processes. This digitalization, combined with the use of AI-driven predictive maintenance, ensures maximum uptime and efficiency of CNC equipment, further solidifying China’s competitive edge in flange manufacturing.

The adoption of such high-caliber technologies not only underscores China’s commitment to quality and innovation but also positions Chinese flange manufacturers as leaders in the global market, capable of meeting the most stringent international standards and project requirements.

Concluding Remarks: The Impact of CNC Machining on the Future of Flanges

The future of flange manufacturing is inextricably linked to the advancements in CNC machining. As this technology continues to evolve, it will further enhance the precision, efficiency, and versatility of flange production. The adoption of CNC machining in flange manufacturing not only supports the growth of industries that rely on these critical components but also drives innovation in materials and designs. With ongoing advancements in CNC technology, the flange manufacturing industry is poised to meet the ever-increasing demands of modern engineering and construction projects.

Other Articles You Might Enjoy

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Precision CNC Machining for High-Performance Industrial Machinery

Precision CNC Machining for High-Performance Industrial Machinery The process of Precision CNC (Computer Numerical Control) machining is at the core of manufacturing high-performance industrial machinery. This technique leverages a computer's…