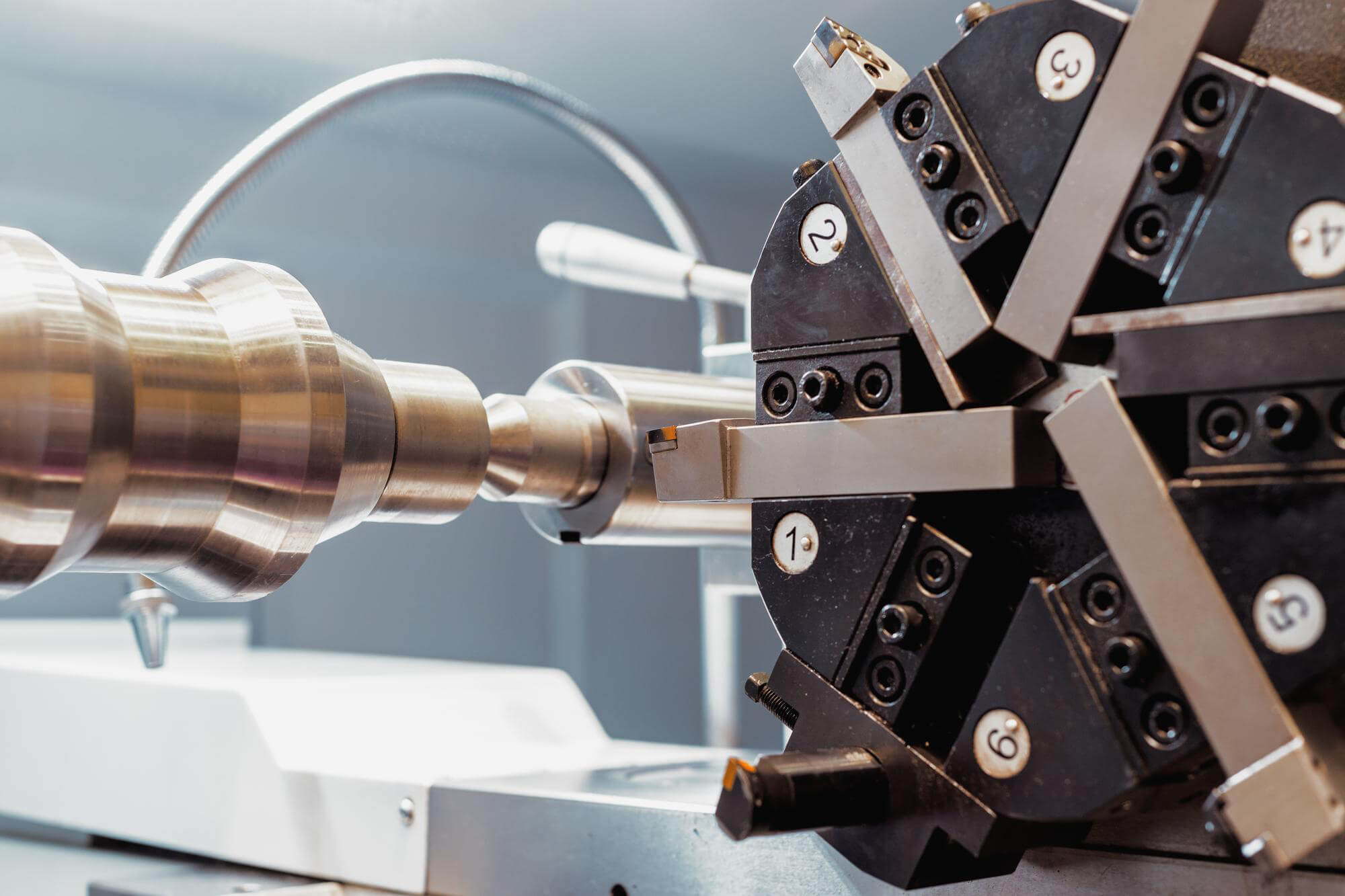

High-speed cutting tools are the backbone of modern metalworking. They play a pivotal role in shaping, cutting, and finishing metal parts with precision and efficiency. In the world of CNC machining, where accuracy and speed are crucial, the right cutting tools can make a significant difference. Let’s dive into the essentials of high-speed cutting tools and their impact on metalwork.

The Role of Cutting Tools in Machining

Cutting tools are the most active elements in the machining process, influenced by their materials and structure. The efficiency, lifespan, and performance of these tools depend largely on the choice of materials and the design. High-speed cutting imposes new and higher demands on cutting tools, making them a critical factor for successful machining.

Essential Characteristics of Cutting Tool Materials

For cutting tools to perform effectively under high-speed conditions, they must possess several key characteristics:

- Hardness and Wear Resistance: The tool material must be harder than the workpiece material, typically with a hardness above HRC 60. Higher hardness means better wear resistance.

- Strength and Toughness: Tools must withstand cutting forces, impact, and vibrations without breaking or chipping.

- Heat Resistance: High-speed cutting generates significant heat. Tools need to maintain their hardness and strength at elevated temperatures.

- Machinability and Cost-Effectiveness: Tool materials should be easy to forge, heat treat, weld, and grind. The cost-performance ratio should be favorable.

Types of High-Speed Cutting Tool Materials

Several materials are commonly used for high-speed cutting tools:

- High-Speed Steel (HSS): Known for its toughness and resistance to softening at high temperatures, HSS is often used for drill bits and end mills.

- Carbide: Carbide tools offer high hardness and wear resistance, making them suitable for high-speed operations.

- Ceramics: Ceramic tools are excellent for high-temperature applications but are brittle and require careful handling.

- Cermet: A composite material of ceramic and metallic components, cermet tools combine the toughness of metal with the hardness of ceramics.

- Coated Tools: Tools coated with materials like titanium nitride (TiN) or diamond-like carbon (DLC) enhance wear resistance and reduce friction.

Cutting Tool Design for High-Speed Machining

Designing cutting tools for high-speed machining involves considering several factors:

- Insert Density: The number of cutting edges on the tool affects its performance. Higher density means more edges in contact with the workpiece, requiring greater machine power.

- Entry Angle: The angle at which the tool enters the material affects the cutting forces and tool life. Negative entry angles are generally preferred for their strength and durability.

- Cutting Mode: The direction of the tool movement relative to the workpiece, such as climb milling or conventional milling, impacts the efficiency and finish quality.

Programming Techniques for High-Speed Cutting

Effective programming techniques are crucial for maximizing the benefits of high-speed cutting tools:

- Tool Path Optimization: Ensure the tool moves smoothly without abrupt changes in direction, which can cause vibrations and reduce tool life.

- Depth and Width of Cut: Balancing the depth and width of each cut is essential for maintaining tool stability and efficiency.

- Feed Rate and Speed: Adjusting the feed rate and cutting speed according to the material and tool type can significantly enhance performance.

Real-World Application and Performance

To illustrate, let’s consider a typical high-speed cutting operation on a steel workpiece:

| Tool Type | Material | Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | Tool Life (min) |

|---|---|---|---|---|---|

| End Mill | Carbide | 200 | 0.1 | 2.0 | 30 |

| Drill Bit | HSS | 50 | 0.2 | 1.5 | 25 |

| Turning Insert | Cermet | 300 | 0.15 | 1.0 | 40 |

High-Speed Cutting Tool Reliability Research

Reliability of Tool Materials

The reliability of cutting tool materials is critical for ensuring consistent performance and longevity. High-speed cutting tools must endure extreme conditions, including high pressure, temperature, friction, impact, and vibration. Therefore, tool materials should have:

- High Hardness and Wear Resistance: To withstand the constant abrasive action during cutting.

- Strong Mechanical Properties: Including tensile strength and toughness to resist breaking under high loads.

- Excellent Thermal Properties: High melting point, oxidation resistance, and stable mechanical properties at elevated temperatures.

- Good Fatigue Resistance: To endure cyclic stresses without premature failure.

Tool Life Models Under Specific Cutting Conditions

Researchers have developed various models to predict tool life under specific cutting conditions. These models help in understanding how different factors like cutting speed, feed rate, and depth of cut affect tool wear and failure. Common models include:

- Weibull Distribution Model: Used to describe the statistical distribution of tool life and predict the probability of tool failure under different conditions.

- Log-Normal Distribution Model: Often used for tools that experience brittle failure, such as ceramic and carbide tools in intermittent cutting.

- Fatigue Life Models: Based on fracture mechanics, these models predict tool life considering cyclic loading and the resulting micro-cracks and fatigue failures.

Designing High-Speed Cutting Tools Based on Reliability

High-speed cutting tools must be designed to maximize reliability. This involves not only selecting the right materials but also optimizing the tool structure and assembly:

- Comprehensive Reliability Modeling: Building a reliability model for the entire tool system, including inserts, tool holders, and fasteners.

- Finite Element Analysis (FEA): Using FEA to simulate stresses and strains in the tool components under operational conditions.

- Dynamic Balancing and Testing: Ensuring tools are dynamically balanced to minimize vibrations and performing high-speed tests to validate the design.

Steps in Designing Reliable High-Speed Cutting Tools

- Define Cutting Conditions: Determine the specific requirements for the cutting operation, including material type, cutting speed, and feed rate.

- Develop Structural Reliability Model: Create a model that includes all components of the tool system.

- Identify Failure Modes: Analyze potential failure points and modes for each component.

- Stress Analysis: Perform detailed stress analysis using FEA.

- Reliability Calculation: Calculate the reliability of each component and the overall system.

- Iterative Design: Refine the design through iterations until the desired reliability level is achieved.

Innovations and Future Directions

Continuous innovation in tool materials, coatings, and designs is pushing the boundaries of what high-speed cutting tools can achieve. Future advancements may include:

- Advanced Coatings: New coatings that further reduce friction and enhance wear resistance.

- Smart Tools: Integration of sensors and IoT technology to monitor tool condition in real-time.

- Material Engineering: Development of new composite materials that offer superior properties for high-speed machining.

Conclusion

The advancements in high-speed cutting tools are revolutionizing the metalworking industry. By understanding and applying the principles of tool material selection, design, and programming, manufacturers can achieve higher efficiency, better quality, and lower costs in their machining operations. The future of metalworking looks promising with continuous innovations in high-speed cutting technology.

Other Articles You Might Enjoy

- High-Speed Cutting Legends Transforming CNC Machining Parts

High-speed cutting (HSM or HSC) is not just a technological advancement; it's a fascinating journey of innovation that has transformed CNC machining parts over the decades. Let's take a trip…

- Comprehensive Guide to Metal Cutting Tools

In modern mechanical manufacturing, metal cutting processes are the most widely used methods, accounting for over 50% of the total workload in mechanical manufacturing. Whether it's a conventional lathe, an…

- Exploring Bead Blasting In CNC Machining(cnc cutting tools Hale)

Bead blasting is a crucial technique applied extensively in the realm of Computer Numerical Control (CNC) machining. This process transforms the exterior aesthetics and surface quality of machined parts, augmenting…

- Understanding Bead Blasting in CNC Machining(cnc cutting tools Miles)

CNC machining is a manufacturing process known for its precision and versatility. One important aspect of this process that contributes significantly to both its functionality and finish quality is bead…

- Optimizing for Speed: Lightweight Materials in High-Speed CNC Machining

Introduction to CNC Machining and the Importance of Speed Optimization In the manufacturing industry, Computer Numerical Control (CNC) machining plays a crucial role. It is a process employing computerized devices…

- Transforming CNC Machining with Smart Manufacturing Techniques

Introduction: CNC Machining and Smart Manufacturing Techniques CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory machinery. This technique enables complete…