The Evolution of CNC Machining: From Aluminum to Composite Materials

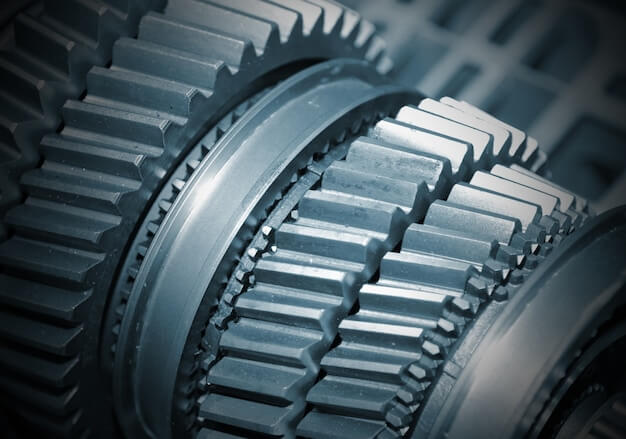

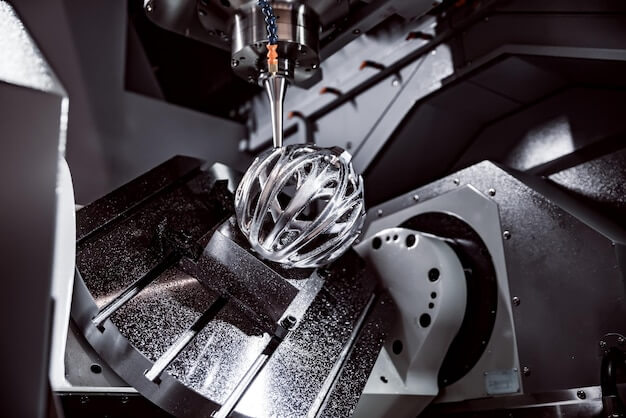

Introduction to CNC Machining CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to initiate and manipulate machine tools, such as lathes, mills and grinders. With the ability to interpret designs generated by Computer-Aided Design (CAD) software, CNC machines perform various tasks, including drilling, cutting, or shaping materials with extreme precision, […]

Zirconium vs. Titanium: Comparing CNC Machinability and Corrosion Resistance?

CNC Machinability and Corrosion Resistance: Zirconium vs Titanium The manufacturing industry often has to juggle a plethora of considerations while selecting materials for product manufacture. Top among these are two properties; CNC machinability and corrosion resistance. CNC (Computer Numerical Control) machinability refers to the ease with which a material can be shaped using automated machining […]

Zinc Alloys in CNC Machining: Benefits and Limitations

Introduction – CNC Machining and Zinc Alloys Computer Numerical Control (CNC) machining is a highly precise manufacturing process widely utilized in various industries to create complex parts. It makes use of pre-programmed computer software that dictates the movement of machinery, which can cut, bore, drill or produce intricate shapes with incredible accuracy. One of the […]

The Significance of Thermal Expansion in CNC Machining Materials

Introduction to CNC Machining and Thermal Expansion In the realm of manufacturing, Computer Numerical Control (CNC) machining stands as a modern innovation that utilizes computer programming in controlling machine tools, markedly increasing efficiency and precision. In a nutshell, these complex machines interpret designs generated by special software, then carry out the requisite operations on the […]

Titanium Grade 5 vs. Grade 23 in CNC Machining: Which is More Efficient?

Introduction: Titanium Grade 5 vs. Grade 23 in CNC Machining In the realm of Computer Numerical Control (CNC) machining, the use of titanium-based materials is quite prevalent due to their excellent strength-to-weight ratio and corrosion resistance. Primarily, two types of titanium are used – Grade 5(Ti-6Al-4V) and Grade 23 (Ti-6Al-4V ELI). While Grade 5 is […]

Choosing Between 304 and 316 Stainless Steel for CNC Machining Applications

Introduction to 304 and 316 Stainless Steel in CNC Machining Applications The selection of the right grade of stainless steel is vital in Computer Numeric Control (CNC) machining applications. Here, we focus on two of the most popularly used grades – 304 and 316. Type 304 stainless steel, also known as A2 stainless, exhibits excellent […]

Hastelloy vs. Stainless Steel in Chemical Processing Equipment: CNC Machining Perspectives?

Hastelloy vs. Stainless Steel in Chemical Processing Equipment: An Introduction In the realm of chemical processing equipment, two commonly used materials include Hastelloy and stainless steel. Hastelloy, a reputed superalloy for its exceptional resistance to severe corrosion environments, is composed of nickel, molybdenum, and chromium with small amounts of other elements such as tungsten or […]

Hardened Steel Grades for CNC Machining: Which Offers the Best Balance Between Durability and Machinability?

Introduction: Understanding CNC Machining and its Significance CNC machining, short for Computer Numerical Control machining, plays an integral role in the construction and manufacturing industries. This advanced technology eliminates manual intervention by automating the controlling processes of complex machines through computers. Primarily, it is used for cutting hard materials like steel into different shapes and […]

The Impact of Surface Finish in CNC Machining: Aluminum vs. Stainless Steel?

Introduction to CNC Machining and Surface Finish Importance CNC machining, or Computer Numerical Control machining, is a manufacturing process involving pre-programmed computer software that maneuvers factory machinery and tools. A significant feature of this technique is its ability to control a range of complex machinery, from grinders to mills and routers – with precision, speed, […]

PEEK Plastic in CNC Machining: Is It a Viable Alternative to Metals for High-Performance Parts?

Introduction to PEEK Plastic and CNC Machining The realm of material science welcomes a game-changing contender, popularly known as PEEK (Polyether Ether Ketone) plastic. A high-performance thermoplastic, PEEK boasts remarkable mechanical properties such as high-temperature stability, excellent chemical resistance, superior strength, stiffness and durability. It provides an edge for industries that necessitate robust materials with […]

Enhancing the Mechanical Properties of CNC Machined Parts through Material Blending

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated production of complex parts. This process relies on computerized controls and machine tools to remove layers from a solid block of material, thus shaping the desired part. The significance of CNC machining lies in […]

Thermal Management in CNC Machining: Selecting Materials for Heat Dissipation

Introduction to CNC Machining and Thermal Management CNC machining stands as a cornerstone in modern manufacturing, utilizing computer numerical control to operate machine tools with high precision. This process is pivotal for creating intricate parts with tight tolerances across various industries. A critical aspect often overlooked is thermal management within CNC machining processes. Effective thermal […]