Introduction to CNC Machining and Surface Finish Importance

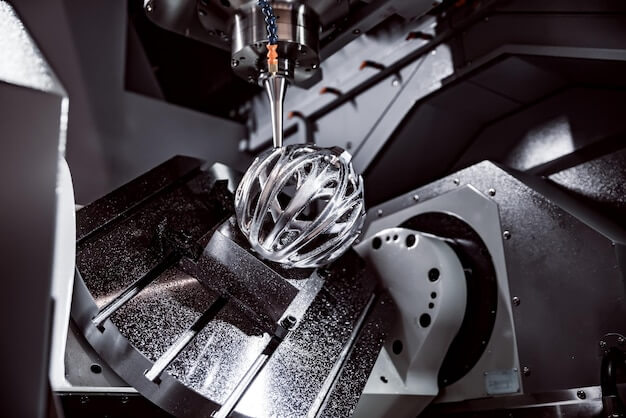

CNC machining, or Computer Numerical Control machining, is a manufacturing process involving pre-programmed computer software that maneuvers factory machinery and tools. A significant feature of this technique is its ability to control a range of complex machinery, from grinders to mills and routers – with precision, speed, and functionality being key attributes. One critical aspect in manufacturing through CNC machining, especially when dealing with materials such as aluminum and stainless steel, is the surface finish.

- A well-improved surface finish can bring several enhancing effects on the final product. These might include increased resistance to fatigue and corrosion, reduced friction, better heat treatment response, and improved appearance which is crucial for consumer-facing products.

- An unrefined surface could result in mechanical failure due to stress concentration – any scratches or irregularities acting as initiation points for crack propagation. Furthermore, poor surface finishes may lead to rapid tool wear, diminishing the overall operational efficiency.

In essence, achieving the perfect balance between material choice and surface finish lies at the heart of successful CNC machining.

Understanding Surface Finish in CNC Machining

In CNC machining, “surface finish” refers to the texture, roughness, and detail level of the exterior surface of a machined part. Achieving an ideal surface finish is crucial as it directly impacts the performance and longevity of the machine component. Multiple factors influence the surface finish quality in CNC machining. The tool type used, feed rate, cutting speed, coolant application, and material characteristics all play significant roles. For example, aluminum and stainless steel may demand different machining parameters due to their unique properties.

- Tool Type: Different tools leave distinct marks on the surface. High-quality tools tend to yield smoother finishes.

- Feed Rate: Higher feed rates can result in rougher surfaces, while lower feed rates usually lead to finer finishes.

- Cutting Speed: Similar to the feed rate principle, slower cutting speeds generally generate smoother surface finishes.

- Coolant Application: Coolants not only prevent overheating but also reduce friction between the tool and workpiece, positively influencing the surface finish.

- Material Characteristics: Hardness, ductility, and thermal conductivity of the material directly affect the surface’s final finish. Softer materials like aluminum often require less aggressive machining parameters compared to tougher ones like stainless steel.

Aluminum versus Stainless Steel in CNC machining

In Computer Numerical Control (CNC) machining, Aluminum and Stainless steel are two commonly used materials that have unique properties with respect to their usability, performance and processing characteristics. Aluminum is lightweight, easy-to-machine and exhibits high thermal conductivity, making it an ideal choice for applications requiring heat dissipation or lightweight components. On the other hand, stainless steel is valued for its strength, resistance to corrosion and aesthetic appeal.

- Aluminum: Key factors that make aluminum popular in CNC machining include its excellent machinability, relatively low cost, light weight and superior thermal conductivity. It’s easier to cut, allowing for higher speeds on the machine which results in shorter lead times compared to other metals. However, one must consider its low hardness and reduced durability when exposed to high-stress conditions.

- Stainless Steel: The main advantages of stainless steel involve its toughness, durability and resistance against corrosion making it suitable for CNC parts intended for long-term and outdoor use. While being tougher implies more effort needed in machining, this also corresponds directly to a product with higher rigidity and capability to withstand extreme conditions.

The choice between aluminum and stainless steel depends largely on the specific requirements of the project including considerations around weight, longevity, aesthetics and environmental condition exposure.

Impact of Surface Finishes on Aluminum

The choice of surface finishes for aluminum in CNC machining plays a crucial role in determining the part’s appearance, functionality, and cost. Different surface finishes such as anodizing, powder coating, and brushing offer varying levels of protection, aesthetics, and durability to aluminum components. Understanding the impact of surface finishes on aluminum is essential for achieving the desired performance and visual appeal in CNC machined parts. Partnering with a online CNC service can provide expertise in selecting the most suitable surface finishes for aluminum components.

Impact of Surface Finishes on Stainless Steel

In the realm of CNC machining, the influence of various types of surface finishes on stainless steel components is significant. Firstly, a smooth finish can enhance the corrosion resistance of stainless steel parts, vital in industries such as food processing or marine applications. For example, marine hardware often uses mirror-like polished stainless steel surfaces to resist saltwater corrosion. Secondly, textured or matte finishes may increase the adhesion properties of stainless steel, beneficial for coatings or bonding processes. An instance of this is seen in medical devices where a specific coating needs to adhere to the stainless steel surface effectively. Lastly, aesthetic considerations also come into play in choosing a surface finish. A brushed or satin finish on stainless steel offers an appealing look that is widely applied in decorative items and home appliances.

- Smooth Finish: Enhances corrosion resistance; utilized in marine hardware.

- Textured/Matte Finish: Increases adhesive properties; used in medical devices.

- Aesthetic Considerations: Dictates use of brushed or satin finish; found in decorative pieces and home appliances.

Comparing Effects of Surface Finishes on Aluminum vs Stainless Steel

The effect of surface finishes in CNC machining varies significantly between aluminum and stainless steel, despite the application of similar finishing processes. The outcome is defined by the inherent properties of these materials.

- Aluminum: Being a softer material, aluminum readily accepts most types of surface finishes. Polishing gives it a shiny, bright appearance while brushing delivers a satin-like finish, both improvements masking minor imperfections. However, its malleability exposes it to easy scratching which can easily mar polished surfaces.

- Stainless Steel: This harder, corrosion-resistant metal responds well to grinding or polishing that removes its oxidized outer layer unveiling a smooth and glossy surface. It can withstand higher wear contributing to extending the component life.

In short, selecting an appropriate type of surface finish for your CNC machined parts requires careful consideration of their functionality, aesthetic requirements, and deciding the best-fit amongst available choices – different materials reacting uniquely under same processes.

Choosing Between Aluminum and Stainless Steel Based on Surface Finish Performance

In CNC machining, the selection between aluminum and stainless steel is primarily rooted in their surface finish performance. The surface finish refers to both the tactile and visual quality of a part’s surface hence impacting its functionality and aesthetics. One should consider several factors when choosing either material for their project.

- Application Requirements: For applications requiring high corrosion resistance and strength under extreme temperatures, stainless steel stands out due to its inherent properties. However, if lightweight and easy machinability are vital, aluminum might be appropriate.

- Economic Considerations: Although aluminum tends to be cheaper than stainless steel, one needs to take into account the total costs including the ease of machining, tool wear, and finishing processes which may affect the final cost.

- Material Properties: Understanding the respective behaviors of each material during different machining operations is crucial. For instance, aluminum usually provides excellent finishes with high cutting speeds, while some grades of stainless steel can have lower surface finish quality at higher feeds and speeds because they are tougher and require more force to cut.

- Finishing Processes: If additional treatments like anodizing or passivation are necessary, know how these processes impact the selected material. Whereas aluminum can be easily anodized to enhance its hardness and aesthetic appeal, stainless steel can be passivated to maximize its corrosion resistance.

However, it’s essential to consult with experienced engineers or material specialists who could offer specific insight based on individual projects.

Summary and Conclusion

In conclusion, the surface finish of CNC machined components—whether they are made from aluminum or stainless steel—plays a significant role in determining their overall performance. In this article, we have explored key factors affecting the surface finish: properties inherent to both materials, machining strategies applied, tools deployed and post-processing methods employed. For instance, while Aluminum’s malleability allows for easier and less costly operations; its softer surface may necessitate additional processing steps like polishing or bead blasting to attain desired finishes. Conversely, Stainless steel being harder is prone to creating rough surfaces but provides superior corrosion resistance.

Understanding these dynamics requires practitioners to make informed choices on the type of material, appropriate cutting tools, feed rates, speeds, cooling systems or even adopting secondary finishing options—all aimed at achieving optimal outcomes. Hence emphasizing, not just mastery of CNC programming and operating skills but also an in-depth knowledge about the performance characteristics of selected materials under different conditions, can result into precision-crafted products with impeccable finishes—a key to customer satisfaction and business success.

The true essence lies in striking the right balance between operational costs, product quality and longevity based on their application needs. To sum up, having a clear understanding of how surface finish impacts CNC machining process in context of Aluminum vs Stainless Steel is fundamental for every machinist and industry stakeholder. It has a direct bearing on the end-use functionality, aesthetic appeal as well as the cost-effectiveness of manufactured parts—a decisive factor in today’s competitive market scene.

Related Posts

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Zirconium vs. Titanium: Comparing Costs and Capabilities in CNC Machining?

Introduction to CNC Machining and Material Selection Computer Numerical Control (CNC) machining is a vital manufacturing process that uses programmed software controls to dictate the movement of factory machinery and…